The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: How to build a wooden shed?

How to build a wooden shed?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to build a wooden shed?

Hi all, I am about to build a small wooden garden storage shed (3m wide x 2.4m deep) on a gravel base. I have been soaking up tutorials, reading the various excellent posts on this forum and on wooden framing and feel fairly confident about most stages but there are a few grey areas that I would love the community guidance on (and will likely lean on you for tips along the way!).

I previously prepped the ground and laid a gravel pad. The plan is to put 2 x 6 treated joists directly into TuffBlocks as the base of the shed and build on top of that.

So my questions are:

Flooring

1. I am looking at treated yellow tongue STRUCAflor is this suitable or is there a better alternative? Treated plywood looks very expensive but I don't mind paying if it means increased longevity.

2. Silly question, but given the fact an exposed tongue in these boards will be at one edge of the shed. Do you just cut these off or just fill the gap with sealant?

Walls

1. What options do I have for external wooden wall panels? I would like something that looks nicer than particleboard or OSB. Is there an outdoor option of these slotted panels? I guess I could use weatherboards but curious at alternatives.

2. Should I use building wrap?

Roofing

1. What are my options here? Just colourbond sheets? If yes, should I still put a plywood/OSB roof on and apply the colourbond to that or just attach it straight to the rafters? I assume I would have lots of gaps if I attach directly to the rafters.

2. If colourbond is the way to go, I'm curious to know what you use so that you don't just have sharp raw edges and what to use for the apex of a pitched roof?

Fasteners

I'm going to use screws instead of nails for framing (Personal preference, if I had a nailgun it might be different 😄). So I don't want to have to pre-drill or anything. What gauge is best, 12g? or thicker? Something like these Buildex RapidDrive Treated Pine Screws 12g x 75mm?

I think that's all I need to know at the moment, once I have these answers I can make my materials order and get stuck in!

Thanks so much

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Ok done! Levelling all 27 blocks wasn't my idea of fun. I had raked and tamped the gravel about 20 times over the last couple of months and it was still off. Most were just raking a bit out and re-tamping but I did have to add some small shims made from sliters of treated joist offcuts to a few of them.

The next step is to add another screw to each joist (So they have 3 in each) and add some joist tape before putting the floor on.

Oh that's a point: Should I use joist tape on the joists and bitumen paint on the bottom of the flooring panels, or is that overkill?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Nice work @mikebarker!

Since this is not a deck where rain falls through it and hits the top of the deck joists, causing decay, I don't see the point in adding joist tape. However, I would be painting the bottom of the STRUCTAflor, as it will help prevent it from absorbing water from the moist environment after rain.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Morning @mikebarker

![]() Now that looks great! Getting things level to start with is a pain but so worth it down the track.

Now that looks great! Getting things level to start with is a pain but so worth it down the track. ![]() Cant wait to see the walls go up!

Cant wait to see the walls go up!

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

@MitchellMc it did not even occur to me that joist tape was for decking for that reason 🤦🏻♂️ I'll certainly do the bitumen paint on the floor though.

@Dave-1 Yeah definitely!

Speaking of walls, I think I'm going to do 400mm on centre studs instead of 600mm. I'd rather it was as sturdy as possible, no point in scrimping on a few studs. Unless you guys think 400mm spacing is overkill for a shed this size?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Afternoon @mikebarker

Mmmm maybe overkill ![]() Its your shed tho

Its your shed tho ![]() Depends on what you may mount on the walls one day. Also if you do change the standard width id suggest to write it down somewhere as I am sure you will be hunting for the stud to hang things one day

Depends on what you may mount on the walls one day. Also if you do change the standard width id suggest to write it down somewhere as I am sure you will be hunting for the stud to hang things one day ![]()

You have reached the point of going "Yeah, I want it that way" ![]() I always think of that point as about the third way up the slope of building something.

I always think of that point as about the third way up the slope of building something.

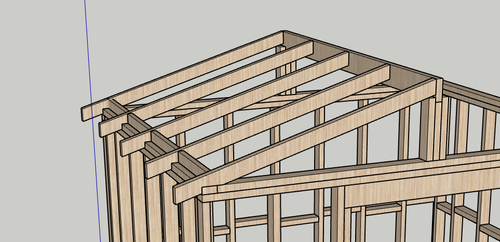

Next point is the frames all up and the final point before the downward run to the end is the roofing trusses ![]()

I can remember standing on the trusses and "Seeing forever" ![]() Makes me want to build all again!

Makes me want to build all again!

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

@Dave-1 Is 600mm the standard for walls in Australia? All the American plans I see are 16" (400mm) on centre. Not planning on mounting much on the wall, a bike or 2 really... but I haven't thought that far either!

Ha I really thought I was locked in with the design but I keep tinkering. I'm not currently doing roof trusses but I expect, given I barely have any room around the structure to get a ladder, I might need to get on the roof to put the roofing on so hopefully my beam and rafter setup can handle me up there 😅

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Hello @mikebarker

Timber wall frames commonly have a depth of either 90 or 70mm, featuring studs with thicknesses of 35 or 45mm, depending on the load and spacing requirements. These studs are positioned at centers of 450 or 600mm. Noggings, serving as spacers, are added between the studs to offer lateral support.

I suggest having a look at this guide - How to build a stud wall.

If you need further assistance, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

@EricL Ah thanks for the extra info. That's interesting that 450mm is a standard. I thought 400mm and 600mm made sense in that it seems most sheet goods come in 1200mm wide sections (Like the cement board sheets I'll be using for the walls) so you can hit a stud right in the middle. 450mm would throw things off a little. If 600mm will still make for a sturdy structure (With 90x45mm studs) then I might just do that as originally planned.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Evening all! My floor has ended up a touch out of square once I added all the joists in. I'm 13mm out 😑 - I've tried jostling it around but haven't been able to make it budge. My plan is to try and square it up more using the flooring sheets, i.e. squeeze it and then secure the floor, holding it in more in place. Sound like a plan? Anything more I can do?

Also, to get things level with the tricky gravel base I've used chocks of treated joists to raise a few of the feet up. This will be ok right? I figure the weight is distributed well enough there won't be a crazy amount of pressure on a single block.

I know non of this is ideal, I'm just keen to proceed with some sensible solutions that doesn't involve pulling things apart to get it perfect.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Evening @mikebarker

Bugger 😕 Know that out of square feeling.

How heavy is the actuall outside square? (Just the four pieces) Maybe you could put the outside square together on the grass then move it over and get that level before adding in the timber joists and tuffblocks? That way you can meausre diagonally to make sure its staying square.

The gravel can be packed underneath once you have the frame right and the joists are down.

Dave

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.