The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: How to build a wooden shed?

How to build a wooden shed?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to build a wooden shed?

Hi all, I am about to build a small wooden garden storage shed (3m wide x 2.4m deep) on a gravel base. I have been soaking up tutorials, reading the various excellent posts on this forum and on wooden framing and feel fairly confident about most stages but there are a few grey areas that I would love the community guidance on (and will likely lean on you for tips along the way!).

I previously prepped the ground and laid a gravel pad. The plan is to put 2 x 6 treated joists directly into TuffBlocks as the base of the shed and build on top of that.

So my questions are:

Flooring

1. I am looking at treated yellow tongue STRUCAflor is this suitable or is there a better alternative? Treated plywood looks very expensive but I don't mind paying if it means increased longevity.

2. Silly question, but given the fact an exposed tongue in these boards will be at one edge of the shed. Do you just cut these off or just fill the gap with sealant?

Walls

1. What options do I have for external wooden wall panels? I would like something that looks nicer than particleboard or OSB. Is there an outdoor option of these slotted panels? I guess I could use weatherboards but curious at alternatives.

2. Should I use building wrap?

Roofing

1. What are my options here? Just colourbond sheets? If yes, should I still put a plywood/OSB roof on and apply the colourbond to that or just attach it straight to the rafters? I assume I would have lots of gaps if I attach directly to the rafters.

2. If colourbond is the way to go, I'm curious to know what you use so that you don't just have sharp raw edges and what to use for the apex of a pitched roof?

Fasteners

I'm going to use screws instead of nails for framing (Personal preference, if I had a nailgun it might be different 😄). So I don't want to have to pre-drill or anything. What gauge is best, 12g? or thicker? Something like these Buildex RapidDrive Treated Pine Screws 12g x 75mm?

I think that's all I need to know at the moment, once I have these answers I can make my materials order and get stuck in!

Thanks so much

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Morning @mikebarker

Mmmmmm been going through your post and the pictures. (Half asleep still lol)

The floor Joist are 3m long, Are you going to put timber the other way before the floorboards or straight on these joists?

Id probarly like the Tuffblocks to be under the corners of the shed. The structure above transfers its weight down through the posts and studs, I am thinking id want the corners supported for sure.

The spacing of the blocks will depend on the bearers and joists if you are using them or setting on the bearers themselves.

You can always "notch" the timber to loose that 4mm of timber (I have done that before with the stirrup posts for the deck) Multiple 5mm depth cuts across the end and then chisel and mallet ![]() Its actually a pleasure to do and I really felt that I acclomlished something when I did it.

Its actually a pleasure to do and I really felt that I acclomlished something when I did it.

As to the skids idea, If you ar using the Tuffblocks, I dont think I would. They should support the frame and weight with teh spacing (I am not sure f the spacing as I havnt use dthem before but may after seeing how you go ![]() )

)

Will have a coffee and wake a little more and think about it.

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Morning @Dave-1! Only the rim joists are 3m. The others are just shy of 2.4m.

Sorry, I'm not sure what you mean by "Are you going to put timber the other way before the floorboards or straight on these joists?"

I feel the same about needing the edges supported.

If I opt to use skids I won't be using Tuffblocks. I'm currently leaning that way.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Morning @mikebarker

Sorry the what I was trying to describe was the way the base is built up to the floor and then walls. So first would be the skids and so on.

Tuffblocks/skids (Piers)

Bearers (The long wide beams that support the overall structure)

Joists (At 90 degreese smaller pieces of timner "joists" that the floor is attached to.)

Would the skids have direct contact with the ground? I am not sure what they are made off.

I like these to rest your bearers on DEKO 250 x 150 x 150mm Instant Concrete Foundation Block

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Thanks for clarifying so rim joist = bearer?

The pressure treated 90x90 posts would be in direct contact with the gravel. An appeal of doing it this way is that it'll be simpler to level the 3 posts. Levelling 25+ TuffBlocks is going to be fiddly.

The TuffBlocks are supposed to be a replacement for the concrete ones. Also, the concrete ones are quite high and I'm already pushing it with how high my structure is. I don't want to go over 3m otherwise I'll need a permit. How many of those would you expect to use?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Hi @mikebarker,

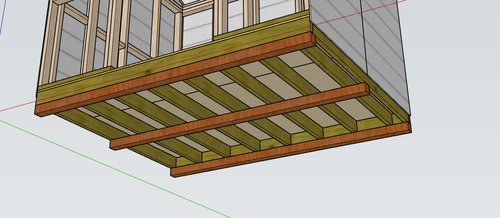

If you want to achieve the floating look, I'd add an extra joist and have the floor extend further out than the wall. It's fine to counterlever joists on a deck, but on a structure like a shed with additional weight, I'd want that weight bearing down directly over the Tuffblocks as per the image below.

On the left and right, it's fine to have the structure extend to the ends as the joists are a continuous span, but the top and bottom worry me as it's just the fixings supporting the weight; that's why I suggest extending out further for the floating look.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Hello @MitchellMc!

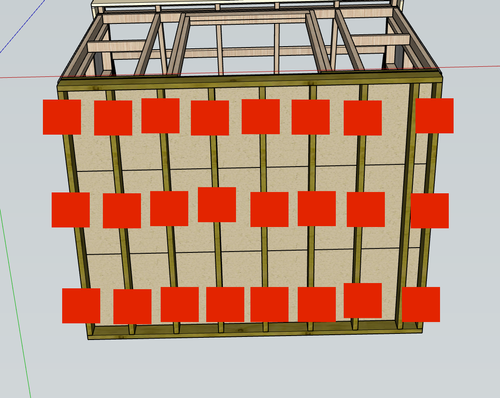

Applying your comment "On the left and right, it's fine to have the structure extend to the ends as the joists are a continuous span" to my design. So would this be ok? (Apologies for the terrible mockup) - essentially inset at the front and back. Note, I will inset as little as I can. They will be close to the rim joists as I can get them, this isn't about it appearing to float 🙂

I'm just curious, gathering as much understanding as I can before I proceed so thanks everyone as always for fielding my questions.

One last question: What are your thoughts on forgetting the blocks and using 3 or 4 90x90 treated posts as skids underneath the joists as shown a couple of posts back? All the tutorials I see use this method when on a gravel base like I have. It will be so much easier to level it all as I'll be able to level the posts before putting the joists on.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Morning @mikebarker

I am not a fan of the skids 😕 It always worries me with timber in contact with the ground will cause rot a lots ooner then expected.

Id even be tempted to have bricks under the skids inset into the gravel so there is a little airgap between the skid and ground.

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

That's fine having the supports as you've pictured @mikebarker.

You'll see the method of posts or sleepers directly on gravel and then joists on those mainly from American guides. That's not really something I've seen a lot of over here. I can't see many reasons why it wouldn't work; it's just not something I've seen implemented before. One thing that would concern me is the timber wicking water up from the ground through capillary action into the structure. You'd certainly need to paint the skids with bitumen paint or install a vapour barrier to prevent this.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Morning @MitchellMc and @Dave-1

Ok, that's great to know that the suggested layout is fine. That makes things a little easier with the amount of Tuffblocks I'll need.

Gosh darn Americans leading me astray again! 😄 Ok, I won't bother with the skids. It's strange it's such a popular choice in the US, with no mention of sealants other than the fact the wood is treated, and on gravel.

On another topic, I had a moment thinking that I should change the orientation of the shed so that the gable roof runs front to back (on the shortest 2.4 part of the shed) rather than from side to side. Reasons are: Better aesthetically and water and pine needles etc will all flow off the sides rather than in front of the door. But my question is: Is there anything wrong with having the rafters on the longest part of the roof? I think it probably makes less sense structurally but probably nothing catastrophic. Like on this example basically.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Hi @mikebarker,

I can't see any reason why you couldn't switch the roof's orientation. It does make sense to have the runoff to the sides instead of the front.

Mitchell

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.