The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: How to fix patio concrete crack and ...

How to fix patio concrete crack and steel post issue?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to fix patio concrete crack and steel post issue?

Afternoon All

I have an issue with my patio and handrail.

The Steel posts that were originally concreted into to the actual concrete slab have expanded with rust and cracked the concrete slab to a point where there are wedge shape gaps of concrete missing.

I was debating to fix the concrete and put new Stirrups in or replace the metal posts with new ones and/or recondition the old ones.

I have decided to go with replace the old ones / maybe reuse the old posts after cleaning and rust proofing.

The way I was going to do it was to clean the cracked area, drill horizontal holes into the slab and put in anchors. Then use expanding concrete to fill around and bond to these anchors and post.

The question I have is anyone have other ideas/solutions to fix the issue?

This is the expanding Concrete I am thinking of using.

These are the anchors I wa sthinking of screwing in half way to give the concrete something to bond to.

Another product Iwas considering but am heading towards the expanding concrete for strength.

First Crack/wedge

Second crack and wedge

I havnt cleaned the area up yet. One question is does anyone know what that yellow powder is? I will use a cold chisel to take out loose pieces of concrete, then drill and fix anchors and then put some right angled formwork (Never done that before) to hold the concrete mix in. Is there something you put on the timber/proper formwork material to make it non stick?

Old post before I tapped it out.

This is the rust and yellow powder? I thought maybe a byproduct of rust? Really dont know. There is another crack in another post but that has not expanded yet.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix patio concrete crack and steel post issue?

G'day/afternoon Dave! @Dave-1

How much concrete is missing from the edge?

From my end it looks like a cosmetic patch?

Do you weld?

I have managed to concrete bolt steel plate into position - then weld pipe or square to create a railing.

I was hoping we could steer away from the stirrup approach?

And I'm not a smart man (I have the sutures to prove it) but how are those concrete screws installed?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix patio concrete crack and steel post issue?

"Is there something you put on the timber/proper formwork material to make it non stick?"

My father used sump oil on concrete form-work.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix patio concrete crack and steel post issue?

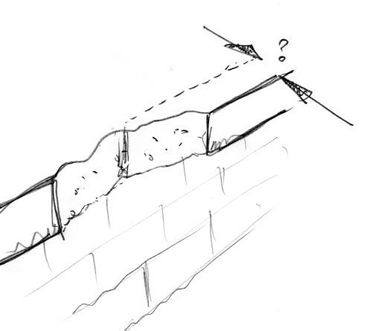

![]() Yeah it pretty much is cosmetic except that it will be supporting a post. Your sketch nails it. Think it is about a 75mm hole.

Yeah it pretty much is cosmetic except that it will be supporting a post. Your sketch nails it. Think it is about a 75mm hole.

No I dont weld, Have thought of learning but never got around to it. I do have access to a workshop at my workplace that has all the trades you could wish for ![]() I just talked to one of them and I can get replacement posts cut so no issue there. Might put some bolts T wise across the base that will be embedded in the concrete. I really dont want to use stirrups in the main patio. Will if I haveto but if I can repair the existing stuff it would be far better.

I just talked to one of them and I can get replacement posts cut so no issue there. Might put some bolts T wise across the base that will be embedded in the concrete. I really dont want to use stirrups in the main patio. Will if I haveto but if I can repair the existing stuff it would be far better.

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix patio concrete crack and steel post issue?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix patio concrete crack and steel post issue?

Hi @Dave-1

It's great that you've received excellent advice from @Noyade. Just to add to the suggestions made, I recommend grinding away any leftover steel still stuck to the concrete.

It might be necessary to build a bit of formwork to hold the concrete patch in place. If you do build form work, just remember to spray the inside of the timber with WD40 before you tip the concrete inside. This will act as dressing allowing you to remove the timber from the concrete face.

If you need further assistance, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix patio concrete crack and steel post issue?

Thank you @EricL

WD40 sounds like a good option. If I use normal/pine timber would I get a nice surface is my main concern (Compared to buying the smooth coated sheet for concrete formwork). I always sit there and go through the steps, end up stressing too much sometimes. Mostly it comes down to me biting the bullet and kicking my butt to get me moving.

I found out that the yellow powder is possibly sulphur. Apparently when they would put the steel posts in they coated the ends of the steel in it to help bind it to the concrete. Will be getting rid of it plus any old rust/steel before hand for sure.

Will keep you posted ![]() hahahahah and no that isnt a delibrate pun.

hahahahah and no that isnt a delibrate pun.

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix patio concrete crack and steel post issue?

Normal Pine timber will give you an acceptable result @Dave-1. I wouldn't be looking for a super smooth finish, as it likely wouldn't resemble the slightly textured surface around it.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix patio concrete crack and steel post issue?

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.