The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- How to reinforce treadmill deck?

How to reinforce treadmill deck?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to reinforce treadmill deck?

G'day All,

So my treadmill is breaking under the workload that is me. Between the rubber belt on my treadmill is a 15mm wooden (mdf?) deck. This is the part that cracks down the middle under my weight.

Customer support has suggested that I attempt to reinforce the deck. I have made my first attempt by screwing wood across the deck, but two out of three of them have come out (I screwed from the bottom up, rather that top down... my bad).

I was wondering if anyone had a simple idea on how I could secure a metal bar across the bottom of the deck?

Note: Pictures to be attached soon.

- Labels:

-

Craft and Hobbies

-

Repairing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to reinforce treadmill deck?

Hi @topper,

I would be extremely hesitant to provide any recommendations, as a failure of the deck could cause serious injuries to the user, especially if this is a powered unit. If the unit is under warranty and it's being used within the guidelines, I would suggest you work with the retailer to find a solution that doesn't involve you making modifications to the machine. All goods need to be fit for purpose, and if the deck has failed under normal use, then that sounds like an issue that would be covered under your warranty.

If this treadmill was purchased through us and is under warranty, then I'd be happy to assist in resolving this issue.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to reinforce treadmill deck?

"I would be extremely hesitant to provide any recommendations" - Me too, that's why I am to the people that know more than I do.

"as a failure of the deck could cause serious injuries to the user, especially if this is a powered unit." - A risk I'm currently taking, with my terrible efforts.

"If the unit is under warranty and it's being used within the guidelines" - It is and the deck isn't covered. Trust me, this isn't my first solution.

"I would suggest you work with the retailer to find a solution that doesn't involve you making modifications to the machine." - If you would note in my post, this was the advice from the vendor.

"All goods need to be fit for purpose, and if the deck has failed under normal use, then that sounds like an issue that would be covered under your warranty." - Nope, hence, why I'm here.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to reinforce treadmill deck?

That's a difficult situation, @topper.

Let me mention @Dave-1 and @Jewelleryrescue to see if they have some suggestions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to reinforce treadmill deck?

Oh tell me about it! IT sucks. I'm on to my third deck and I'm under the recommended weight.

I understand and will happily say no one suggesting anything can or will be held responsible for my efforts to put a suggestion together.

Honestly, the main thing from this would be the best fastener. I can tell you now, wood screw from top down doesn't work. I might need to nut and bolt it?

If I go with metal, I have to ensure there is still a little flex, just not so much it'll rattle or still break the wood.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to reinforce treadmill deck?

Afternoon @topper

That sounds like a pain to deal with 😕 Frustration level high and I feel it.

So a couple of questions for you. Lets see if I have this right.

Picture one with the end of the tape measure sitting at the same level as the tread part of the unit?

Picture two is a board that is directly below this?

Picture three is the width of the board.

How much space do you have to play with underneath the cracked board?

Does the surface of that black base board have to be flat (no screw heads sitting high? )

If you have around 25-30mm of space to play with you could mount some 20mm square bar (Metal Mate 20 x 20 x 1.6mm 3m Galvanised Steel Square Tube ) across the width in three places and bolt through the timber and the bar (you will need to drill holes to match.)

If the surface has to be smooth then you can countersink the tops of the bolts and use countersunk bolts instead to give you that flat surface.

If you have less space then that then use some flat bar (Australian Handyman Supplies 20 x 3mm x 2m Steel Flat Bar ) Id probarly go for 4 pieces across the width if using this. So the only added height to the flat panel would be 3mm for the bar + nut height + washer height.

Id also look for a wider head of countersunk screw or allow for a washer in the process. The more points of attachment across either bards will help it stop flexing.

If you havnt already done so it maybe an idea to grab the exact measurements of the backing board so you can make another if needed? Its only chipboard and that stuff dosnt like standing up to much 😕

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to reinforce treadmill deck?

Hi @topper

Like @Dave-1 ideas but i get the feeling that top deck needs to flex to allow move nateral running lower knee shock and the belt to move too

Think of a wrestling ring that floor needs too bounce. Admitadly different reasons .

To make a robust yet flexable frame replicate your base made out of 19mm smooth ply of good quaiity.

Make a exact replica using there attachment points etc asa a guide.

Hope this is easy for you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to reinforce treadmill deck?

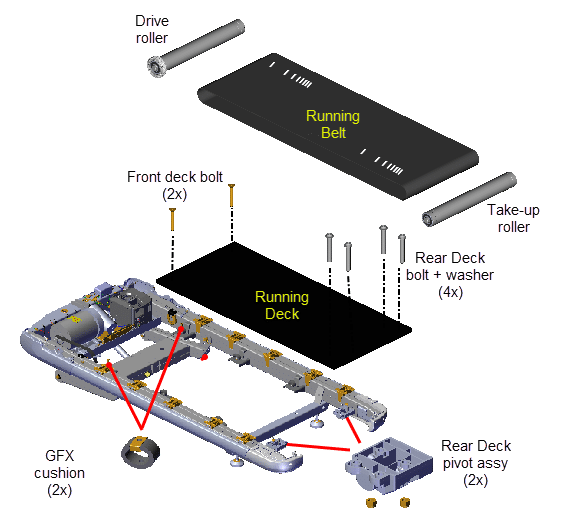

Here is a better generalised schematic that may help with what I'm dealing with.

Currently I have a piece of wood (I had 3, 2 have dropped off). going horizontal across the deck to stop it snapping in half.

Between the running deck and the underside of the belt isn't much, approximately 21mm.

Does the surface of that black base board have to be flat (no screw heads sitting high? )

- That's correct, there is a plastic cover that goes over the top. But I might be able to put pieces of wood between the screw heads to lift up everything evenly? (Or just sink it like you suggested.. I should finish reading before replying)

Similar to what @Jewelleryrescue suggested below, just wondering if there would be a way to fasten the metal to the wood in a way that would still allow for a little flex as well as not 'slapping'/bouncing against the wood with each step.

Id also look for a wider head of countersunk screw or allow for a washer in the process.

- Do you think this would allow for a little flex in the metal?

Sorry for delayed response.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to reinforce treadmill deck?

Hi @topper

thanks for the exploded diagram of what we are dealing with.

Having sean whats going on it should be pretty easy to do.

The key repair he is replacing the MDF deck board with Ply I know it will out perform mdf with out the need of extra reenforcings of any kind. Second thing isto cut running board out of a single sheet so it is all solid no joins.

Now Your original board was 15mm I am now probably recommending staying close to this thickness as performance tolerances maybe effected.

Closet and in a smaller piece is

1200 x 596mm 18mm Plywood Pine BC Grade If that will match your running deck ine one single peice is imortant, You may need larger raw material size?

I/N: 0390159

$49

Now to need to cut you ply as close to the original running deck board ask bunning to cut to you board dimentions at a small cost.

Now your suspension comes from two gfx cushions that attach to screws on under side of your board.

So the next step is to lay the old board on top of the new perfectly (clamp it will help) and drill the same size holes you look like you have 6 holes to drill. Now ideally countersink all the holes on top deck so the screw heads will tighten up below the level of the timber board. any lump will where the belt out in that spot and failure in time.

If you use your original screws should work as the have the threads that go into the metal frame mountng points. As the ply is many times stronger then mdf in this application.

Best to counter sink a little deeper so counter sink and drop the screw in it until is is under. Dont forget plastic sheet will lift the head a little too so allow for that.

Craftright 3pce Countersink Bit Set

$6.91

Your timber foot slapping ( sound)can be greatly redueced by a peel off foam tape stuck on to the metal frame all the way down where ever the board and metal make contact. making little cushions.

Moroday 24 x 5mm x 10m Grey PE Foam Tape

$9.53

Hope this is all clearto you and it all works. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to reinforce treadmill deck?

Evening @topper

I still like the idea of the flat bar straps across the width with the washers (if needed) The flat bar is mainly to give it strength. You could replace the sheet with plywood as @Jewelleryrescue suggested but think normal use will end up with the same issue without those bars being installed.

Countersinking the timber board is what I mean, the flat board would be under the timber sheet and wouldnt need to be countersunk. The only reason Id put a screw within a larger countersunk hole on the timber would to spread the contact area around. You also wouldnt have to have them at the 4 attached points of the drawing, you could space them half way between them as they are only going to be supporting the timber from flexing so much.

Dave

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.