The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: How to make a saw-table?

How to make a saw-table?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to make a saw-table?

Hi everyone, when I need to cut long pieces of wood or boards, I find my circular saw awkward to keep straight, especially when I have to start leaning across the workpiece to get to the far side. I don't have a proper workbench, just an old Black & Decker workmate stand that I can clamp the pieces to. Now, If I could find way to mount my circular saw under the workbench, so I could feed the work through it, I think that might be a solution. Yes, I could go and buy a table saw, but storage space is at a premium and I'm not sure I would use it enough to justify the cost. Any thoughts would be welcome.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a saw-table?

Hi @Noyade

I wonder how accurate this table saw is? My only other concern is the safety aspect of the saw itself. A few timber screws holding the saw does not fill me with confidence.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a saw-table?

I think I will stick to my Bosch GTS 10 XC.

Unless someone wants to buy me a MiniMax CU410 Elite Combination Machine.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a saw-table?

Hi @Brad

"Belt driven with a washing machine motor."

And I'm sure it worked a treat. My father's hybrid table saw is powered by a floor polisher motor - 1 1/2 HP.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a saw-table?

Not sure if this is a washing machine motor?

But he made a disc sander outta a spare motor from somewhere.

Used a belt pulley to mount the face.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a saw-table?

Given the ease that the motor stalls I think it may be 1hp or less.

Used a linkage belt.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a saw-table?

Some of these home-built contraptions are wondrous bits of ingenuity and lateral thinking, but somewhat scary in these OHS days. However, like many things, they were "of their time" and served a purpose without too many fingers being lost. You would have to hope that anyone clever enough to think of the design, and then build it, would have the common-sense to know how to use it safely!

My search for a machine for the current time has brought me back to the $699 Makita unit. (Bunnings i/n 0118523). I had a chance to get my hands on one and it seems to hit the sweet spot for price, build quality and being a well-known brand. Now I just have to start saving my pennies, and clearing a suitable space in the garage. Thanks to everyone for your information, ideas and stories about table-saws.

Happy building.

John.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a saw-table?

It's great to hear you managed to get your hands on the Makita and found it suitable @VulcanJohn. What convinced you that it was the most suitable machine? Less play in the guides?

I'll be looking forward to hearing your review on it.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a saw-table?

Hi @VulcanJohn,

I bought one of the cutting guides from Bunnings a couple of years ago, for the very reason you're describing.

Best thing I ever bought, once you know the offset from the edge of your saw blade to the edge of the base-plate, it's too easy to make good,

straight cuts every time.

Sorry to go off topic here, but I was watching a YouTube video by a guy in the US and he was using some type of solid foam sheet insulation as a base for his timber and having the saw blade cut into it with the whole setup on his workshop floor.

Has anyone here heard of a brand name for this material and if it can be sourced down-under?

Cheers,

Mike T.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a saw-table?

Hi @MitchellMc

I watched a fence contracting team trim the bottom of a newly installed picket fence the other day. They were using a Festool plunge saw and rail system.

Very impressive. They must be able to connect the rail as it was a 10 metre length? Wanted to ask, but they looked busy.

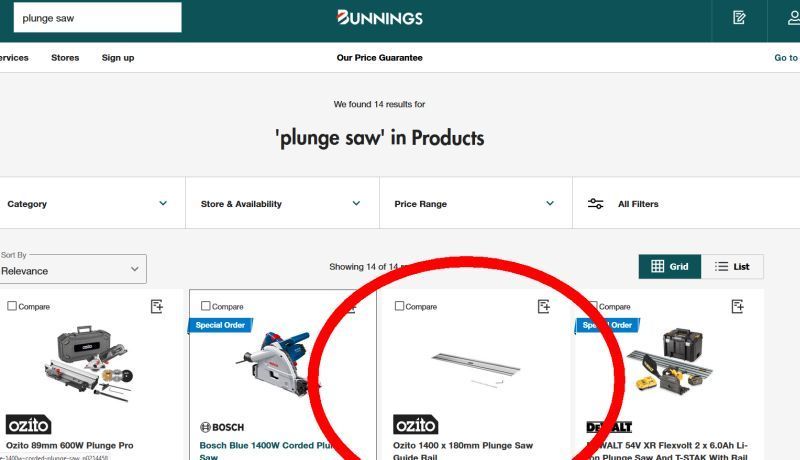

Does Ozitio still make a plunge saw? I only see the rail...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a saw-table?

The kit still appears on the Ozito website @Noyade, so we should be able to order it in. They might be changing the model hence it not appearing on the webpage. I can't imagine it's going anywhere as plunge saws are becoming more popular with D.I.Y. enthusiasts. I was using a Makita plunge saw a few weeks back and was very impressed.

Mitchell

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.