The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: How to build a wooden shed?

How to build a wooden shed?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to build a wooden shed?

Hi all, I am about to build a small wooden garden storage shed (3m wide x 2.4m deep) on a gravel base. I have been soaking up tutorials, reading the various excellent posts on this forum and on wooden framing and feel fairly confident about most stages but there are a few grey areas that I would love the community guidance on (and will likely lean on you for tips along the way!).

I previously prepped the ground and laid a gravel pad. The plan is to put 2 x 6 treated joists directly into TuffBlocks as the base of the shed and build on top of that.

So my questions are:

Flooring

1. I am looking at treated yellow tongue STRUCAflor is this suitable or is there a better alternative? Treated plywood looks very expensive but I don't mind paying if it means increased longevity.

2. Silly question, but given the fact an exposed tongue in these boards will be at one edge of the shed. Do you just cut these off or just fill the gap with sealant?

Walls

1. What options do I have for external wooden wall panels? I would like something that looks nicer than particleboard or OSB. Is there an outdoor option of these slotted panels? I guess I could use weatherboards but curious at alternatives.

2. Should I use building wrap?

Roofing

1. What are my options here? Just colourbond sheets? If yes, should I still put a plywood/OSB roof on and apply the colourbond to that or just attach it straight to the rafters? I assume I would have lots of gaps if I attach directly to the rafters.

2. If colourbond is the way to go, I'm curious to know what you use so that you don't just have sharp raw edges and what to use for the apex of a pitched roof?

Fasteners

I'm going to use screws instead of nails for framing (Personal preference, if I had a nailgun it might be different 😄). So I don't want to have to pre-drill or anything. What gauge is best, 12g? or thicker? Something like these Buildex RapidDrive Treated Pine Screws 12g x 75mm?

I think that's all I need to know at the moment, once I have these answers I can make my materials order and get stuck in!

Thanks so much

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Thanks @MitchellMc that tread looks good also.

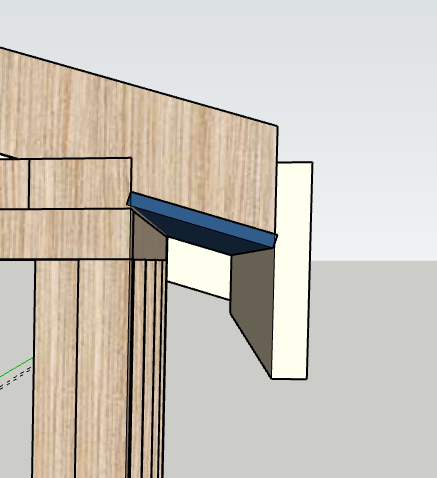

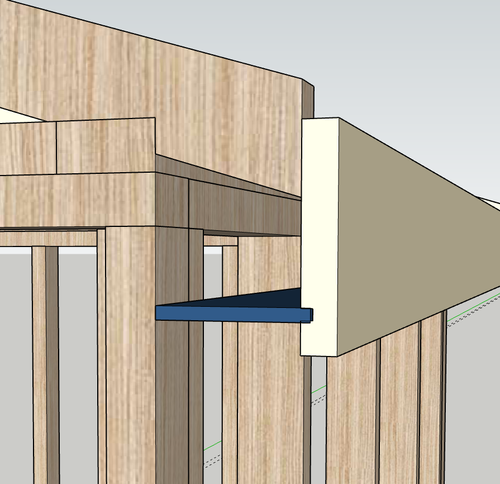

@Dave-1 Ha ok, I'll do eves 😅 where do you attach soffits? To the rafters on a diagonal? I have those fascia boards with the indentation at the top and bottom for (I assume) soffits but then:

A. What do I attach them to?

B. There is a huge void left as the soffit is so low down, or is that ok?

See here

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Afternoon @mikebarker

Id attach to the rafters, I do know of the slots on the facia but not sure what theyare for. The way I figure it is the facia boards are what the gutters are attached to so factor that in when putting the tin sheet on the roof (I didnt when I built my deck and kinda nervous about when I do)

Also the second photo woul mean you need to install another piece of timber on the wall to support that side of the facia board.

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Howdy chaps! I hope your weekend is going well. The shed build is going really well, mildly slowed by some cladding indecision on my part but I've decided to go with full Colorbond (Cladding and roofing).

Given the material choice for cladding I have questions about preventing water ingress in the window and the door. Purely due to the corrugated nature of colorbond. Using the top of the window as an example, assuming I put some flashing around the window cavity, I assume there is then just gaps where the corrugation dips? I know I'll be using the foam inserts for the roof gaps but is that also applicable here? And with the door, unless I use colorbond on the door exterior and match up the corrugation to the external walls, water will easily get in.

I'm sure this is a problem that has already been solved but I am clueless!

So, adjacent to my water concerns, to give my door some coverage, I am now considering adding eves to the roof above the door. But I've already partially completed the rafters - without the extension component for the eves. I opted for thinner 90 x 35mm timber, so my question is, with a small overhang (I was thinking approx 400-500mm) can I stick with this thinner timber or do I need to replace my rafters with 90 x 45mm? There will be the weight of the colorbond and the fascia boards. It would be great to be able to keep what I have and just replace the rafters with longer pieces, and not the blocking that sits in between the rafters but I'll do it if needed.

Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Afternoon @mikebarker

Like your idea ![]() I have never thought of how to fit a window or a door to a corrogated wall before. First thought was maybe check out some sheds around the place or pics of sheds online and backwards figure out how to?

I have never thought of how to fit a window or a door to a corrogated wall before. First thought was maybe check out some sheds around the place or pics of sheds online and backwards figure out how to?

Second thought was what requirements are def needed, A Window sill with a bit of a slope, and maybe a top window with a bit of a slope? the sides can be covered in trim. For the door the same idea, A sill with a slope and a cap to it so the water if it gets on the tin runs down and is naturally funneled to the edge of the timber.

For the extension, you could add legth to a few of your trusses by bolting/screwing long lengths to the existing rafters side by side with the extended bit for the overhang? That way the strength you have is still there if not added to making it more solid.

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Hi @mikebarker,

Have you got the window unit that you plan to install? This would likely shed some light on how to go about waterproofing it best.

They often have a flange around them that can be taped using a butyl tape such as Consolidated Alloys 48mm 15m Butyl Double Sided Tape at the waterproofing weak points. But it is hard to tell the best method without seeing the window unit.

I would suggest to create a cantilevered overhang of 400-500mm you would need to increase the size of the timbers. This is less because the weight from above, and more from the cantilever that is unsupported from underneath. If the timbers are unsupported from below, their own structure is what is supporting any load applied to it, so larger timber is always better.

You would also need to change the orientation of the timbers. In supporting structures, the 90mm should always be oriented vertically as there is much more support for downward forces in this orientation and all engineering for structures is done with this orientation in mind.

The next thing I note with this gable end, is that the roof is supported by only one post under the ridge beam. I don't know if you've removed some things for ease of viewing in your Sketchup file, but there should definitely be additional vertical members at 450mm spacings where I have circled below.

Just some thoughts, happy to help further if you require it.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

@Dave-1 I thought you'd like the idea, you're the main reason I'm doing it 😆. I can't argue with your logic. I have been looking at sheds but not focusing enough on the door solutions. I'll keep my eyes out.

I can't quite picture what you're suggesting for the overhang, any chance of a doodle?

@JacobZ This is the exact window I have, a "standard" aluminium house window I believe.

Great points on the wood, I figured as much. Putting the batten wood vertically makes complete sense but I might have some issues fastening them to the rafters as I'll need some huge screws, unless I toenail them but doesn't sound ideal. What would you suggest? Just considering options: Do you think 90x45mm oriented horizontally would be adequate for a small overhang? If not, would 70x45mm vertically be a better option? (I'm asking partially because I designed this shed to be dangerously close to the 3m height limitation without a permit (In Victoria) and using 90mm on their side might push me past a point of comfort 😬)

Also, I do have posts where you suggested to support the gable ends, this SketchUp file is incomplete but thanks for checking!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Afternoon @mikebarker

Lets see if I have it right...

Existing look, No extension of eaves over the door or window

For the doorway, Think long triangular frame that is attached to the wall either side of the door up and into part of the end truss. You mayneed to add in some posts for the triangle to be screwed to in the truss space is all. This way the water will keep away from running down and into the top of the door. btw it dosnt need to be that steep.

Green = vertical posts screwed to the studs in the wall and truss.

Pink = sloped timber to attach the awning to.

Red = horizontal support the distance from the wall you want.

This is what I was referingto about extending the top of the trusses. Attaching a longer piece of timber to the side of the truss that extends past the existing point. If you have the length of timber stretched over a larger distance it will only firm up the strength of the truss.

Pink = existing top of truss

Green = new pieces added. Would suggest a min of three but at least a half foot either side of the window...

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

@Dave-1 Ah so you mean create an additional structure over the door and window. Well, the sides already have eves so hopefully the sides will be ok, I just need to be able to seal around the window well enough. It's the gaps, due to the peaks and valleys in the corrugation of the colorbond that are the issue.

Door-wise, I don't mind the idea but much prefer the look of a full overhang extending the roof from the battens. I was thinking I'd see how I went with water ingress with the overhang and then add something like you suggested if I need it. If I can create a door perhaps with the corrugation of the colorbond panels perfectly lined up then it'll probably be fine.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Afternoon @mikebarker

Yeah pretty much, I was thinking how to effectivly seal the corrorgations and was tryingto make sure water couldnt get into it so would need to waterproof the peaks and ridges.

You could always mark out on a wide piece of timber the peaks and valleys of a sheet of tin and then use a jigsaw to cut the shape so it slots into the groove and then waterproof with a silastic of some kind (sealing the timber with paint as well) But I am not sold on that idea as I figure it raises the chance of rot down the track.

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build a wooden shed?

Agreed. I must be missing a trick. When you look at the doors on any of the pre-packed colorbond sheds they don't appear to have anything going on to stop water getting in the door seals - https://easyshed.com.au/

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.