The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Kitchen

- >

- Re: How to join timber panels to form L-...

How to join timber panels to form L-benchtop on pantry cabinets?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to join timber panels to form L-benchtop on pantry cabinets?

Hi there!

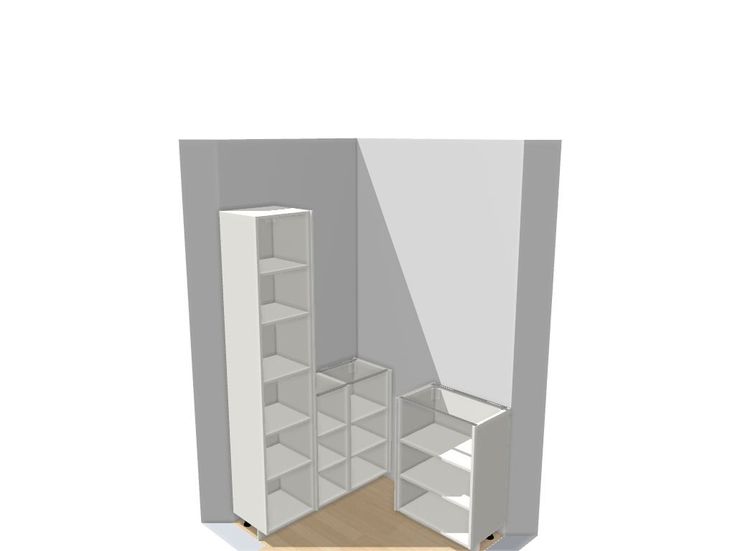

I'm going to be installing some kitchen cabinets in our small pantry and need some advice about benchtops as it will need to fit an L-shape over the cabinets.

I'm thinking of a long bench top spanning across the wider pantry over the gap and onto the corner cabinet top. Then I'd complete the L-shape with a smaller panel over the remaining space over the cabinets (which will join to the high cabinet). The cabinets have a depth of 37mm. What's a recommended overhang for benchtops?

I was thinking of something like this panel (https://www.bunnings.com.au/specrite-1800-x-405mm-18mm-timber-panel-beech-fj-laminated_p8330198) with a couple coats of polyurethane.

What's the best approach to making the L look nice? I think I'll leave a 5mm (or less) gap to the walls and high cabinet and caulk those gaps, but what's the approach to join the two bench tops together. They will all be secured to the cabinets from the underside, but not sure how to deal with the butt joint part.

Thanks!

Solved! See most helpful response

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to join timber panels to form L-benchtop on pantry cabinets

Hi @barydos,

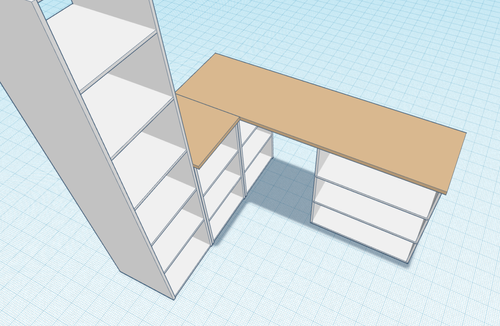

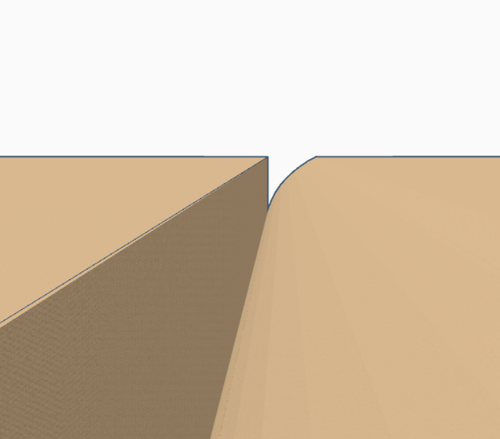

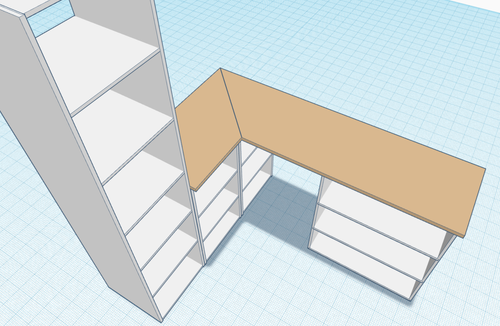

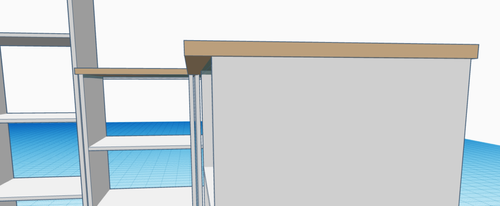

If you look at those panels' edges, they've been chamfered. This means that if you butt join the two bench sections together, there will be a chamfered side joined to a square-cut side. I've created the below renderings to illustrate.

To avoid this, I'd recommend a mitred diagonal join in the corner.

Given the cabinets are 370mm deep, and the panel 405mm wide, the overhang of 35mm would be around right.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to join timber panels to form L-benchtop on pantry cabinets

Thanks for the reply @MitchellMc

I understand your concern around the chamfered edge, that totally makes sense.

When it comes to joining the mitre cuts, would you recommend applying wood glue to join them? And BEFORE securing these to the cabinets?

And afterward, do you think I'd need to do anything extra for that join. Or would you expect the cut to be seamless enough to else as is?

Thanks again! Excited to do this soon

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to join timber panels to form L-benchtop on pantry cabinets

Wood glue will be needed, and the Kaboodle Benchtops Join Kit would be useful to get a seamless joint. It includes biscuits if you wish to use them for alignment, but that would require a biscuit joiner. It also includes benchtop joiners that pull the edges together and compress the joint. At a minimum, you would need wood glue and flat brackets to join the bench sections. I'd recommend joining the sections in situ to avoid any fitment issues.

You could achieve a seamless join if your mitre cuts are perfect (I'm not that good). I suspect a little timber filler would assist in hiding any inconsistencies.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to join timber panels to form L-benchtop on pantry cabinets

Based on what you've said, I'm interested in going down the benchtop joiner kit path. Also the description of that product says it has 12mm benchtop joiners. Which is that metric referring to?

Just thinking that I'd need to consider what size boring bit to use to fit the joiner, and also the fact the benchtop is 18mm thick - so the depth of the cavity to fit the joiner.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to join timber panels to form L-benchtop on pantry cabinets

I'm so sorry @barydos. I've provided an incorrect product there, as it's only designed for benchtops with a minimum thickness of 20mm. We do have the 2200 x 600 x 26mm Beech Laminated Panel that would give a more premium look, and its thickness would allow you to use the joiners. You'd need to trim the width down as it's 600mm. On the plus side, it doesn't appear to have chamfered edges, so you could have a butt-join which would be easier to achieve than the mitre. Unfortunately, the Taskmaster and Hafele joiners are also 18mm thick and are not suitable for your 18mm panel.

On the Kaboodle kit, the 12mm is a reference for the nut size, and the spanner is included for that. The bored hole to accommodate the head is to be 35mm, and it would need to be 18mm deep to accommodate the thickness of the joiner. Then, the channel needs to be around 12mm for the bolt. Here are the Kaboodle instructions on the joiner installation. I'll also include the video below.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to join timber panels to form L-benchtop on pantry cabinets

Thanks for that clarification and video, all super useful resources for me!

Moving forward, I think I'll do some practice attempts with some off cuts first. Anyway, is the order basically getting the measurements and joining done first (no glue) and then disassemble to apply oil (then reassemble after)?

On that note, I remember applying some water-based polyurethane on my office desk (used the beech laminated panel) and had some struggles (used brush and random orbital sand 3 times basically with 2 hr waiting in between). Is there a good video for the proper technique on this? I was also a bit unsure on the proper way to discard the excess varnish. Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to join timber panels to form L-benchtop on pantry cabinets

Hi @barydos,

Were you going to use an oil or polyurethane? Either way, I'd suggest cutting done first, applying your oil or poly to any hidden edges that will be hard to access once the bench is installed and then joining the sections. Once the bench is in place, you can apply your coating to it.

What sort of struggles did you have applying the polyurethane coating? Typically, you'd require three coats and a light sanding in between them.

Excess varnish can be dropped off to your local recycling and waste management centre that accepts paint cans.

Please let me know if you have further questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to join timber panels to form L-benchtop on pantry cabinets

Thanks @MitchellMc.

My bad, I think I'll go with water based poly. I hear it seems to do well protection-wise and require less maintenance thereafter.

I think I previously struggled with probably over brushing? And also the varnish that would drip over the side of the timber panel - would just sand it down again after I guess. And still not too sure what's the best approach to cleaning the brush and storing it between coats as well.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to join timber panels to form L-benchtop on pantry cabinets

Hi @barydos

The best way to keep your brush in good condition is to wash it after you've finished painting for the day. However, if you are letting it sit in between coats, I suggest getting a small bucket and filling it with water. Place the brush in the bucket making sure that the water level is above the brush head.

When it's time to apply another coat, tap the brush on the side of the bucket to remove the water. Wrap the brush in an old tea towel to remove all the excess water in the brush. Do it several times and when the brush is dry you can then begin painting again.

Just remember to give your brush a proper wash at the end of the day. Do not leave it sitting in the bucket overnight as this will damage the brush ends.

Here is a handy step-by-step guide: How to restore wooden furniture (the techniques used are applicable to your benchtop)

If you need further assistance, please let us know.

Eric

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.