The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: Steel shed corner converted into an ...

Steel shed corner converted into an Exercise Area

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Steel shed corner converted into an Exercise Area

I have been asked about this project before so I thought I'd share details with the Workshop.

This article is focussed on lining the walls more than on equipping the area.

My home workshop is bigger than I need now that my projects are mostly home repairs, so I was able to partition a quarter of it off as an exercise area, which I need more.

A walled off space was essential for the purpose, to prevent being distracted by what else I could do (such as my queue of workshop tasks) and it also minimises dust transfer from the Workshop area.

[Pic No 1 is a panorama, which is why the walls look bent. It shows the two steel-framed walls and equipment. Pic No 2 is normal aspect, looking in through the open door.]

The steel structure is hot in summer and cold in winter and not visually appealing to be in (not that it’s exactly beautiful now), so I lined the inside of the two steel walls with MDF and also created two inner "walls". The outer walls can hold equipment and the inner walls are to keep out the dust.

One inner is made up of timber cupboard units (from Ikea), which house our extra gear, such as Christmas decorations, camping gear, etc. [Can be seen on RHS in the panorama view.]

The other return wall has a door and is otherwise made from Cube units from Bunnings, which I stacked together, added backs to stiffen them and keep dust out of the exercise area.

They give me more storage in the workshop too. [pics No 3, 3a & 3b] I ran a timber rail across the top of them (not shown), bolted to the top of the cupboards at one end & through to the wall of the workshop. The cube units are not designed to be free standing so are bolted to the overhead timber rail with brackets, to keep them firmly upright and able to take the load.

I created a timber framework within the steel one to attach the MDF wall lining sheets with minimal holes in the steel structure, and also to keep the joins aligned. They would otherwise bend in or out away from each other over time. The extra framework allows me to attach some equipment to the walls without risk of the attachment points being pulled away when any exercises put moving forces on the wall.

My starting point was the timber upright next to the centre steel upright near the roller door. [shown in pic No 4]

Issue No 1: I didn't want to drill any holes through the main C channel uprights of the workshop because the holes could compromise its strength.

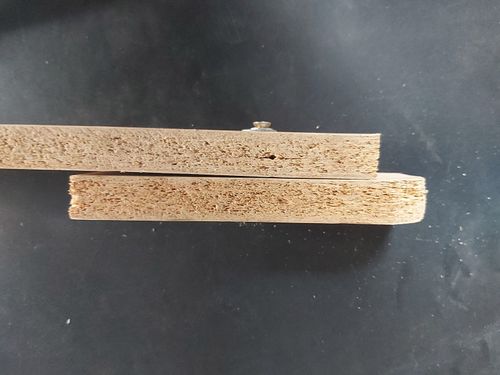

I made up pivoting clamps, out of pine strips. [pic No 5] (I didn't photograph the originals; this demo-model is just chipboard.) The length is the inner width of the channel. They have rounded ends so they can be put into the channel upright and then twisted to horizontal. They are held in place by the edges of the C channel’s opening. [pic No 6 & 6a ] Loosely screwed to the centre of that piece is another piece, which is longer and can pivot. [pic No 5]

When the inner piece is in place the outer piece is swivelled to the horizontal where it clamps tightly against the steel's slot's edges. [pic No 7] It also protrudes beyond both the steel upright and the added timber upright, giving me places to bolt the timber upright to. The clamps don't need to be all that strong, since the timber framework is holding all the weight... they just need to stop the timber from falling over or moving away from the steel.

They were made like this because they had to be inserted between the C channel uprights and the shed's outer covering. I didn't have any access to that area for drilling or screwing anything there, even if I wanted to. They were tensioned by pre-adjusting the pivot screw (trail and error). [Pic No 8] I attached short timber strips to the timber upright, at right angles, next to the pivoting clamps. This meant I could attach the Pivot clamp and the upright protrusions, screwing in from the bottom or top. [Pic No 9]

The same method attaches a timber upright to the steel at the outer corner, and to the horizontal rail that runs across from the roller door to the corner for attaching the top edges of the MDF panels along that sloping-top wall. The return wall of the workshop has a steel C section running horizontally across the top, so I just screwed the MDF directly to the top, after installing the vertical joining strips.

The bottom joining strips had nothing to attach to, so I added scrap Melamine pieces behind them to spread the load while drilling and screwing MDF to them. [Pic No 10] (The joiner strips then don’t touch the walls.)

Importantly, for my set-up, I added timber uprights [Pic No 11] at the places where the Suspension Trainer frame [Pic No 12] was to be mounted in the corner. (The other wall’s support upright isn’t shown. The closer upright in pic 11 is to where the MDF strips join.)

I didn't want to trust timbers screwed just into MDF knowing that the structure would be pulled forcefully outward when in use. (I have a b-i-l who visits from overseas and is into fitness seriously, so his bigger and stronger body would give the gear a good workout.) To ensure I could find those uprights once the MDF was in place, I wrote the distance from the corners to the uprights and photographed that. [Pic No 13] Digital cameras are so useful.

But that was the hardest phase of the project. Handling the 16mm thick MDF was awkward due to its size and weight (doing that alone is not recommended in hindsight), but otherwise was just routine measuring, cutting, positioning and screwing into place.

I sat the bottoms on plastic L shape strips to stop moisture seeping into the MDF from the concrete floor.

I added a small timber strip along the top of the "Cube" wall, aligned with the roof support steel, so I could attach Corflute to fill in that upper gap while also letting light through. Did the same along the tops of the cupboard "wall", adding strips along the sloping roof-line too as there wasn't anything there to hold up the Corflute. This was a cheap, easy to cut and very effective answer to keeping out the dust from the workshop without losing light. [Can be seen in Pic 3 & 3a]

The wall-mounted equipment is fixed where there are timber supports behind the MDF (mostly at the joins).

The mirror [in Pic 2] is on a hinged frame so it can swing to wherever a mirror may be needed to check that you are moving as you should.

A shelf unit holds any small gear and importantly - houses a music source. In my case it's a PC and a now defunct TV (pre-digital tuning, but has a video input socket for a computer, so it's a big screen PC at no extra cost).

This enables me to have exercise guidance videos and music to exercise to.

Exercise:-

It has been proven by a team of scientists in Canada that exercise movements on a beat (not just background music) has a developmental effect on both brain and muscle, which exercise alone does not have. (i.e. It develops fine, controlled reflexes in complex movements, not just good looking muscles that may not work together usefully.) My interest is in keeping my balance and coordination in good shape and maintaining strength, not doing muscle training for the Olympics or competitions, so the rhythm aspect is essential in my exercise area - and it makes it more pleasant to be there. As does the fan.

(Maybe I’ll even paint the walls someday. With music & on the beat of course; “Rock and Roller”.)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Steel shed corner converted into an Exercise Area

My apologies for the photos that are out of sequence. It was not clear to me how to get them where I wanted them to be before posting.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Steel shed corner converted into an Exercise Area

What a fantastic transformation, @TedBear!

I love how you've got creative with the fixing methods for the structure. The space is so much more inviting now, and I'm sure it is excellent for working out in.

Many thanks for the amazing amount of details you've added to your project. I trust any of our members dealing with a similar situation will appreciate all the information.

Great work.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Steel shed corner converted into an Exercise Area

This is such a great project @TedBear. The TV is a great addition as I also use videos from time to time, so much easier for early morning workouts to just follow along! Really interesting research about how music beats has on brain and muscle development, I will need to make a new playlist.

Thank you for going through your wall lining process. I am quite interested in the flooring, which material did you choose? What size space did you create in the end?

Katie

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Steel shed corner converted into an Exercise Area

Thanks for the encouraging feedback Katie & Mitchell.

Floor size is 2700 x 2500. It is in a 6 metre square shed, but that's outside measurement and the cupboard units use up some floor space.

Covering is just cheap, short pile, hard wearing, carpet from Bunnings. We were limited in choice due to the cupboards already being there with the door bottoms, which open into this area, being close to the floor. If I had known that I would be doing this when I installed them, I would have put the cupboards on a plinth to get more clearance. However, since we are only doing lightweight stuff, that covering is ample for us, with a mat for when lying on the floor and a bench than can be laid on too.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Steel shed corner converted into an Exercise Area

Hi @TedBear

Having a dedicated space for working out is a great idea. I can never do any exercises in the house as there are too many things to distract me. Especially if I am right next to the fridge and pantry. I'm in total agreement with @MitchellMc on your ingenious way of mounting timber to the steel structure. This technique should come in handy for members who have the same type of shed structure and are wondering how to mount timber onto it.

That TV I reckon is your best idea. Aside from looking up data for health and fitness. There are youtube clips that focus on bike paths that are anywhere from 30 minutes and upwards. Not only do you get the exercise, but you get to see some fantastic scenery around the world.

Again, thank you for sharing your converted exercise area.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Steel shed corner converted into an Exercise Area

Thanks @EricL . Great tip. I'll look up some of those videos so I can at least mind-travel while exercising!

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.