The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- How To

- >

- How to build a portable workbench

How to build a portable workbench

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Intermediate

Build a portable three-tiered workbench that includes storage space for your tools.

Inspiration for this project comes from Workshop member @Sarma1 who built a custom portable workbench with tool storage.

As this project involves power tools, please follow all safety guidelines provided by manufacturers and use the recommended protective gear, including face mask, safety glasses and gloves.

Steps

Step 1

Measure and cut the timber lengths.

This three-level workbench is 900mm tall, 1000mm wide and 600mm deep.

Clamp the 2400 x 70 x 35mm Pine pieces securely to the sawhorse. Now use a tape measure and pencil to mark the lengths according to the cut list below. You can use a combination square to mark straight lines.

Cut list:

• Four pieces measuring 930mm for the front and back of the cabinet shelves

• Eight pieces measuring 600mm for the sides of the top, middle and bottom shelves. Plus the drawer sides

• Two pieces measuring 765mm for the front and back of middle shelf

• Four pieces measuring 900mm for the legs of the table.

MDF Panel:

• One piece measuring 850 x 600 x 12mm for middle shelf.

Cut the above pieces using a circular saw. After cutting, sand the timber edges using 240-grit sandpaper.

Step 2

Assemble the benchtop, lower shelf and pull-out shelf frame.

Take two pieces of 930mm cut timber and two of the 600mm pieces. Form a rectangle shape with the 600mm pieces on the outside and the 930mm pieces on the inside. Position the corners together by doing a simple butt joint. A butt joint is where two timber pieces meet at right angles.

Clamp the pieces tight on the sawhorse and drill a pilot hole in the middle of the corner where the 600mm and 930mm pieces meet.

Now drill a single 10G 65mm screw into the pilot hole. Repeat the process for the remaining three corners. Once the first rectangle frame is assembled, repeat the steps above to construct a second one.

Assemble the middle pull-out shelf frame in the same manner but using the 765mm pieces at the front and back.

Step 3

Attach the front legs.

Position both the rectangular frames on the floor spaced 700mm apart. Make sure they are standing vertically with the long side facing up.

Take one 900mm timber piece and position its end to the right corner of the first shelf. Use a clamp to keep them together and use your combination square to make sure the leg is straight.

Drill four pilot holes on the top part of the leg, 18mm away from the edge of the timber. The first two on the right should be in line with the end of the 600mm piece. The second two on the left should be in line with the end of the 930mm piece.

Once the holes are drilled, use four 10 x 65mm screws to attach the 900mm piece to the corner of the first shelf.

For the bottom shelf use your tape measure to leave a gap of 100mm from the foot of the table to the bottom of the frame.

Clamp the bottom shelf into position and use your combination square to make sure the leg is straight. Repeat the screwing instructions above to attach the bottom shelf to the first leg.

Repeat the steps above to attach the left leg of the table.

To attach the back legs, turn the work table over so that the attached legs are now facing the floor. Repeat the same steps used to attach the front legs. Once all the legs are attached, stand the table frame up.

Step 4

Attach the shelves.

Double check these measurements against your unit before cutting.

Use your pencil, tape measure and combination square to measure and mark the Specrite Okoume timber panel according to the following:

• One piece measuring 1000 x 600 x 22mm cut from the 2100mm timber panel for bottom shelf

• One piece measuring 1100 x 600 x 22mm to be used for the top shelf.

Clamp the panel onto the sawhorse and cut it with a circular saw according to the measurements above. After cutting, sand the edges using 240-grit sandpaper. Position the 1100mm panel on the top shelf and the 1000mm at the bottom shelf to make sure they fit.

Remove the panels from the table’s shelf frame. Use your Kreg jig and position it 70mm away from the internal corner of the frame. Use timber off-cuts as spacers to ensure that the mounting holes are in the correct position. Drill the mounting holes using the drill bit that comes with your Kreg jig.

Once the mounting holes are drilled, reposition the tabletop and clamp it in place. Use 8G 30mm screws to screw your tabletop to the shelf frame.

Step 5

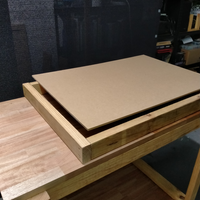

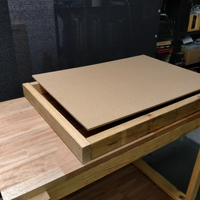

Install the pull-out shelf’s top.

Measure and mark 835 x 600mm on the MDF panel using a tape measure, combination square and pencil. This will be the top of the middle shelf.

Clamp it on to the sawhorse and cut it with a circular saw. After cutting, sand the edges using 240-grit sandpaper. Position the 835 x 600mm panel on the pull-out shelf frame created in step two and use four 8G x 30mm screws on top of the corners to secure the MDF panel onto the drawer frame.

Step 6

Position the drawer sides.

Using your combination square put a pencil mark on the table legs 300mm below the bottom of the top shelf. Do this on all four legs. Starting on the left side of the table take one of the 600mm timber pieces and position it below the pencil mark. Use clamps to position the timber piece accurately. Drill two pilot holes in front of the legs then use two 10G 65mm screws to anchor the timber piece in place.

We will now refer to this piece as the drawer side. It’s where the drawer slides and shelf will be attached to. Do the same anchoring steps for the back of the drawer side and repeat the process for the right-hand drawer side.

Step 7

Install drawer slide.

Take your drawer shelf and position it standing with the 600mm side facing up. Position your drawer slide at the front of the drawer frame and place it just under the MDF panel top. Once in position, pull the drawer slide to reveal the drawer rail and screw the front of the rail to the timber frame, using the screws that came with the drawer runner. Making sure that the drawer slide is still square, keep pulling until you reach the middle of the rail and screw it in place as well.

To screw the end of the drawer rail, pull down on the drawer runner release clip. This will allow you to remove the drawer slides body.

Take the drawer slide body and position it at the start of the 600mm drawer side. Place it 10mm below the top of the drawer side, clamp it to the drawer side and screw it in place with the screws that came with the drawer runner.

Repeat the same steps to attach the drawer slide on the other side of the drawer.

Once both drawer slides are installed slide the drawer into position and make sure that the release clips have locked into place.

Step 8

Install tool holders.

We’ll be using a basic tool holding system using 42x19mm FJ timbers. Cut the timber to 100mm lengths, cut 10 pieces to start with and cut more if you require more to hold your tools.

Position your tools on the pull-out shelf making sure to use all the available space. The first tool in my line up is my Ozito sander. Place two pieces of the 100mm timber pieces that you’ve cut on either side. Mark their position with a pencil all around.

Put the sander and timber aside and drill two pilot holes for each timber holder with your drill. Put the first timber piece back into position and use 8g x 30mm screws and screw it into place from the bottom of the shelf.

Repeat the process for the rest of the tools.

Step 9

Attach wheel supports and wheels.

Flip the table on the left-hand side so that you have access to the bottom of the legs. Place a 600mm piece between the legs of the right-hand side of the table. Secure with clamps and make sure they are square. Secure the 600mm pieces by screwing them to the bottom of the legs of the table with 10 x 65mm screws on both sides.

Now place one fixed castor wheel in the centre where the leg and wheel support meet. Secure the wheel in place using 8G x 25mm screws. Repeat the same process for the other three castors. Put the locking castors on the legs of the left-hand side of the table.

You have now successfully built a portable three-tiered workbench.

Materials

- Nine pieces of 2400 x 70 x 35mm untreated non-structural Pine

- 2100 x 600 x 22mm SpecRite Timber Panel Okoume FJ Laminated

- 42 x 19mm 1.8m DAR Pine Premium - 1.8m

- 9mm MDF Panel Standard 1200 x 600mm

- 10G 65mm timber screws 100 pack

- 8G 50mm timber screws 100 pack

- 8G 30mm timber screws 100 pack

- 8G 25mm timber screws 100 pack

- Goliath Standard Drawer Slide Pair - 550mm.

Tools

- Screwdriver

- Drill driver

- Circular saw

- 2.5mm drill bit

- Kreg jig with drill bit

- Tape measure

- Combination square

- Ruler

- Clamps

- Pencil

- Sawhorse

- Table

- Safety gear, including face mask, safety glasses and gloves.

Images

- Tags:

- Garage and Shed

You must be a registered Workshop community member to comment. Please join Workshop or sign in to join in the discussion.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.