- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

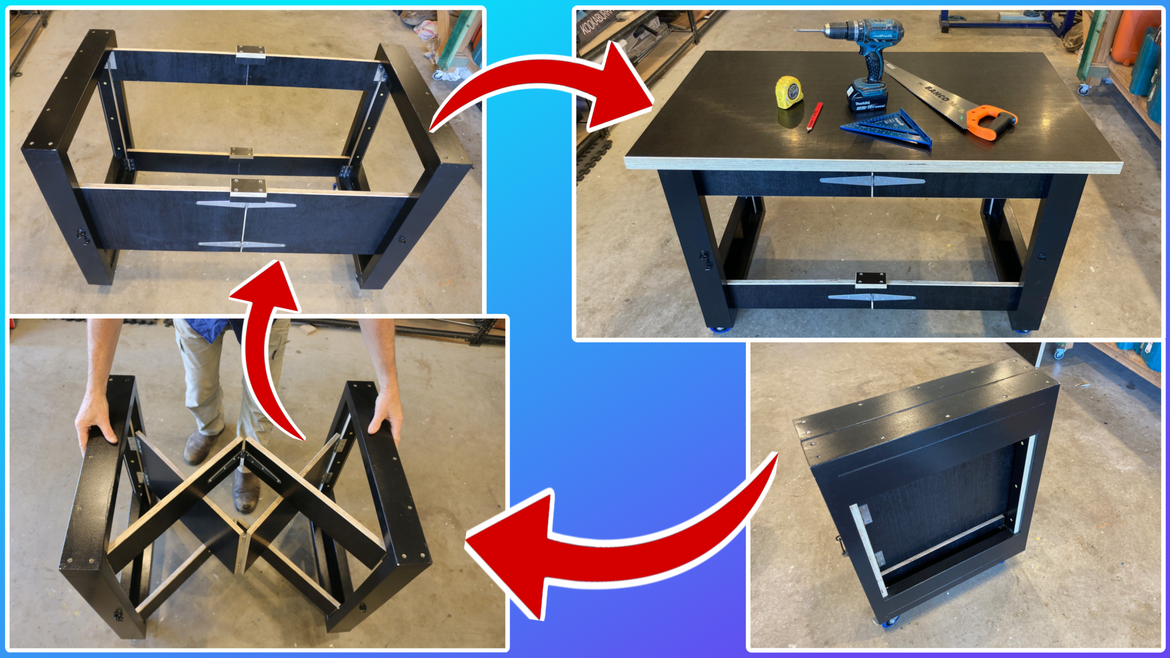

The Amazing Folding Workbench for Small Workshops. A surprisingly easy project that is a great solution for small work spaces where a static workbench is not suitable as it takes up to much room. Every DIY enthusiast needs a workbench and now there isn’t an excuse not to have one especially if you are like me and only have a single car garage. Head on over to my DIY For Knuckleheads YouTube Channel for the Easy to Follow Step by Step Tutorial 👍😁

Materials

Tools

17mm Black Formply x 1: 2400mm x 1200mm https://www.bunnings.com.au/specrite-1800-x-1200mm-17mm-formply-f17_p0390220

90mm x 42mm Dressed All Round Pine. 3 x 2.4m. The reason l chose this is that it is generally blemish and knot free so looks better and can be painted easily: https://www.bunnings.com.au/90-x-42mm-2-4m-f7-h3-treated-pine-primed-losp_p0021265

150mm Strap Hinges x 4: https://www.bunnings.com.au/pinnacle-150mm-zinc-plated-strap-hinge-2-pack_p4230231

70mm Butt Hinges x 8: I used polished silver hinges but l reckon these black ones would look pretty cool: https://www.bunnings.com.au/lane-70mm-black-matte-fixed-pin-butt-hinge-2-pack_p0097023

Cabin Hook: https://www.bunnings.com.au/pinnacle-65mm-matte-black-cabin-hook_p0038295

75mm Casters with Brakes x 4: https://www.bunnings.com.au/easyroll-75mm-90kg-blue-rubber-swivel-brake-castor_p0073907

7 1/4" Makita Circular Saw: https://www.bunnings.com.au/makita-185mm-1200w-corded-circular-saw_p6240318

Makita Cordless Drill: https://www.bunnings.com.au/makita-lxt-18v-cordless-brushless-hammer-drill-kit_p6240427

Makita Orbit Sander: https://www.bunnings.com.au/makita-300w-random-orbital-sander_p6240110

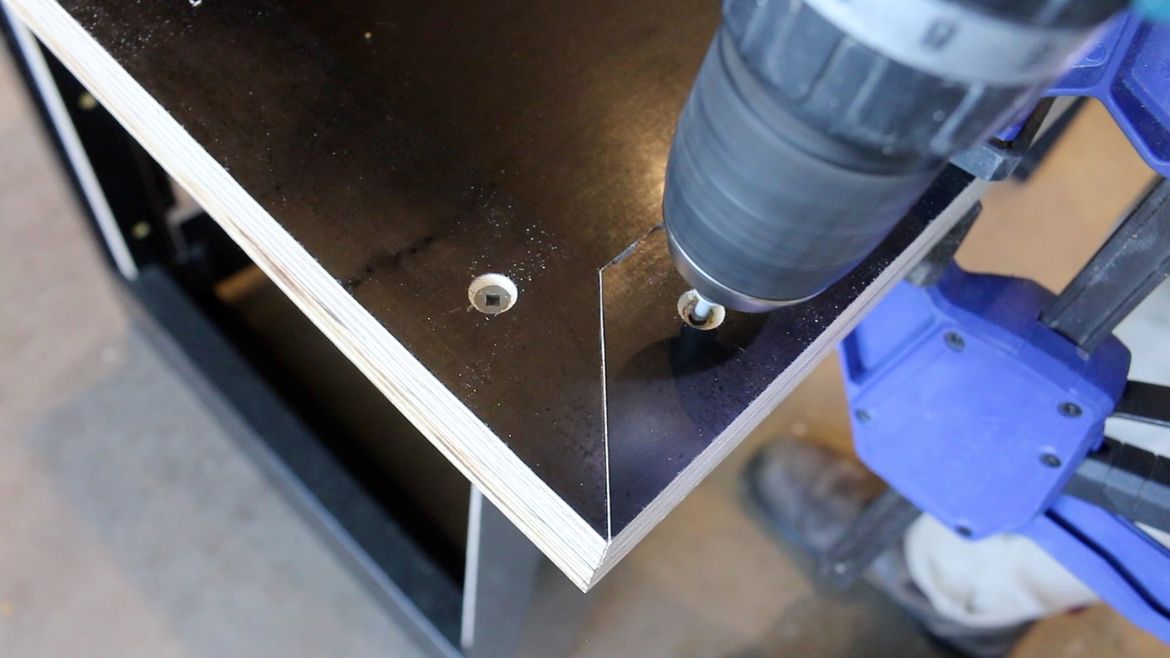

10 Gauge Macsim Countersinking Bit: https://www.bunnings.com.au/macsim-10g-clever-tool-standard-head-blister-pack_p2360698

Empire Speed Square: https://www.bunnings.com.au/empire-180mm-laser-etcher-rafter-square-true-blue_p0154654

Makita Trim Router: https://www.bunnings.com.au/makita-18v-brushless-laminate-trimmer-skin-only_p6240437

Steps

Step 1

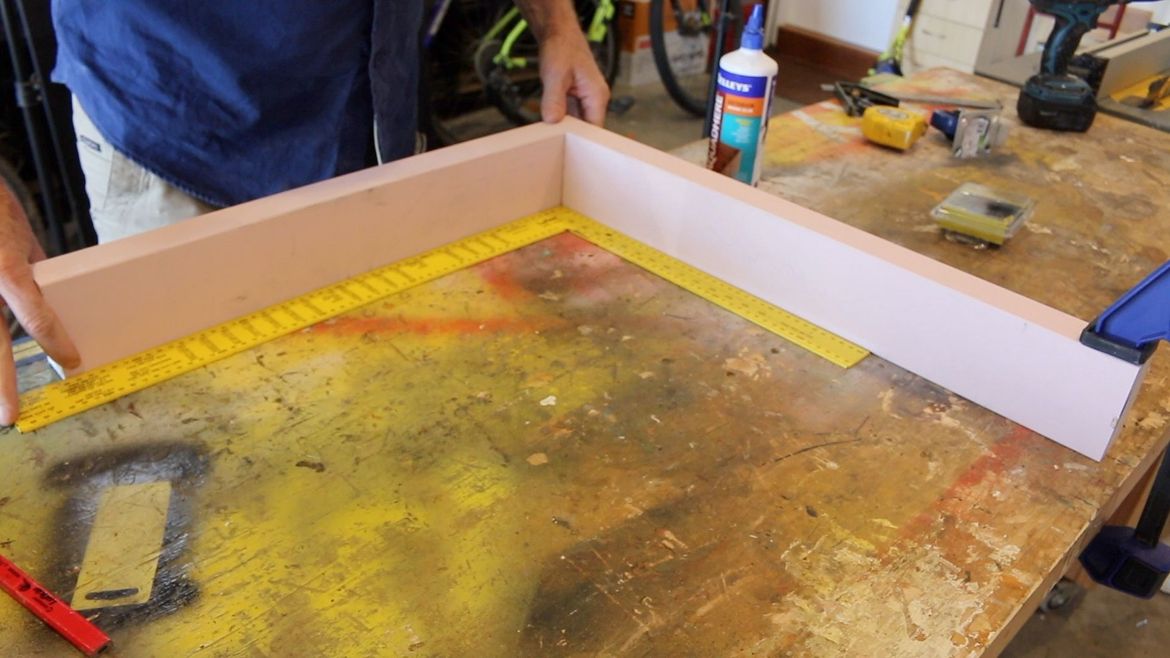

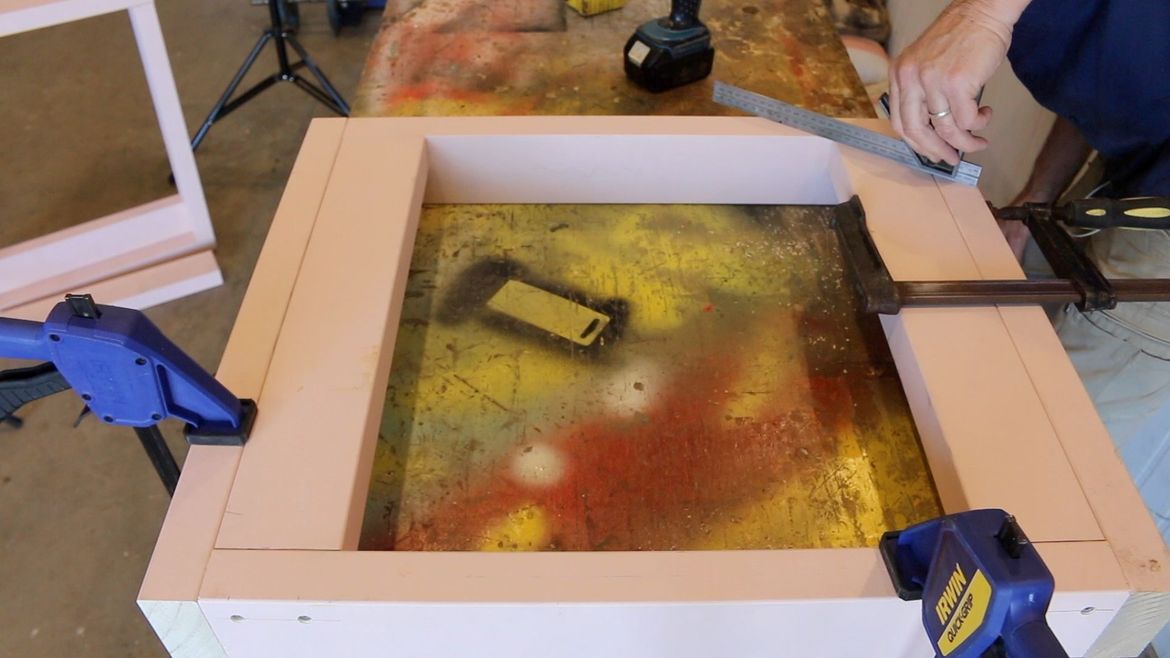

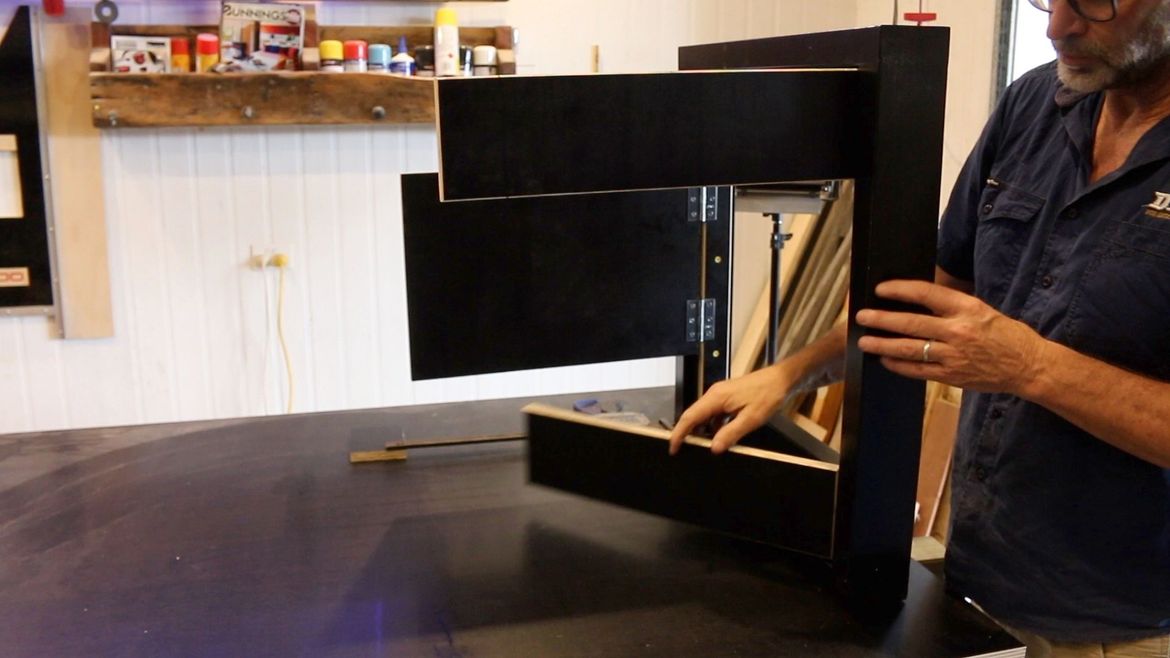

1/10Cut the pieces and assemble the two end frames. It's pretty important to get these exactly the same as they need to fold neatly in together.

Step 2

2/10Patch all the holes and imperfections with Spacfilla. https://www.bunnings.com.au/selleys-180g-spakfilla-rapid-gap-filler_p1231864

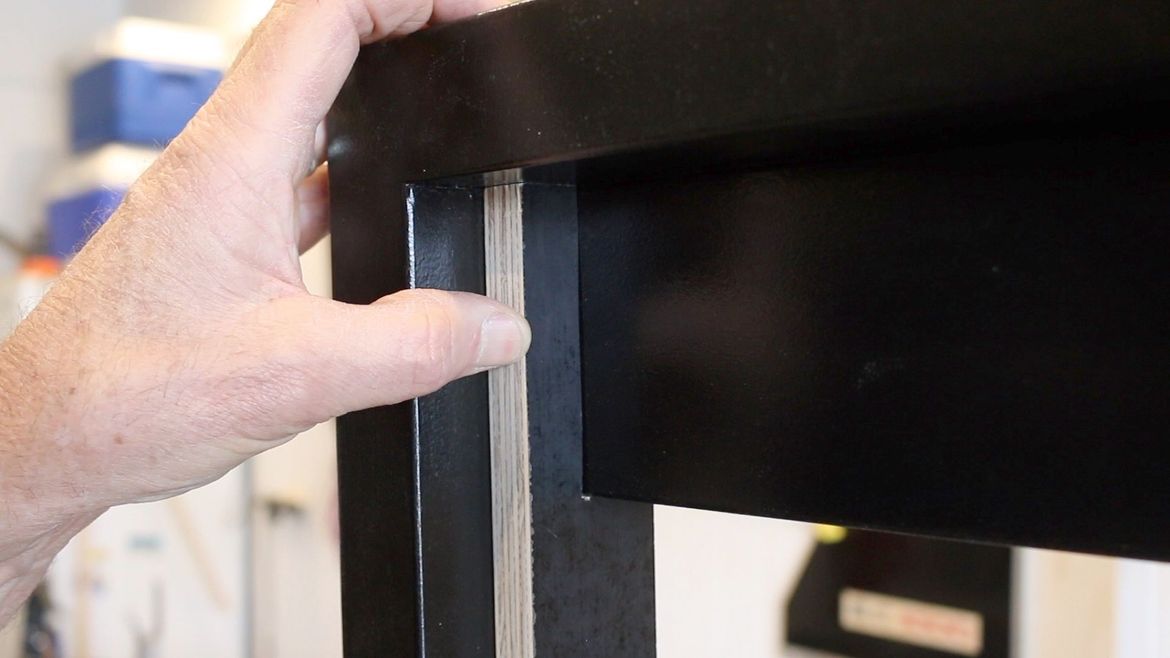

Apply an undercoat and then follow that up with two coats of gloss black enamel.

Step 3

3/10Cut the pieces of Formply for the folding arms. A great way to get these nice and straight is to clamp a straight edge to the formply and run your saw up against it. Of course if you have a table saw you can always use that. Once the pieces have been cut it's time to assemble and connect to the two end frames.

Step 4

4/10Give the folding arms a test. As you can tell from my facial expressions l was pretty surprised by how well it all folded together!

Step 5

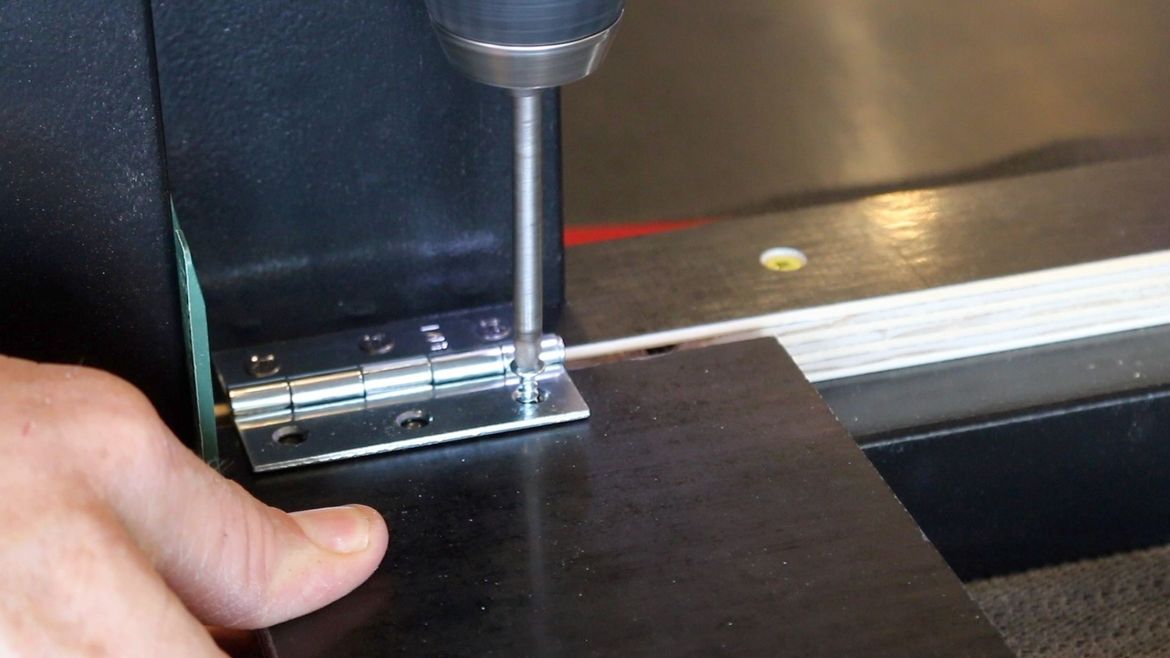

5/10With the frame now complete it's time to cut the formply for the top. I've added some thickness to the edge of the bench top by screwing a strip of formply to the underside of the bench top.

Step 6

6/10With a router or even some sandpaper, chamfer the edges of the benchtop to get rid of the sharp edge.

Step 7

7/10Make up the stabiliser blocks for the folding arms. These prevent the arms from folding in and keep the arms straight.

Step 8

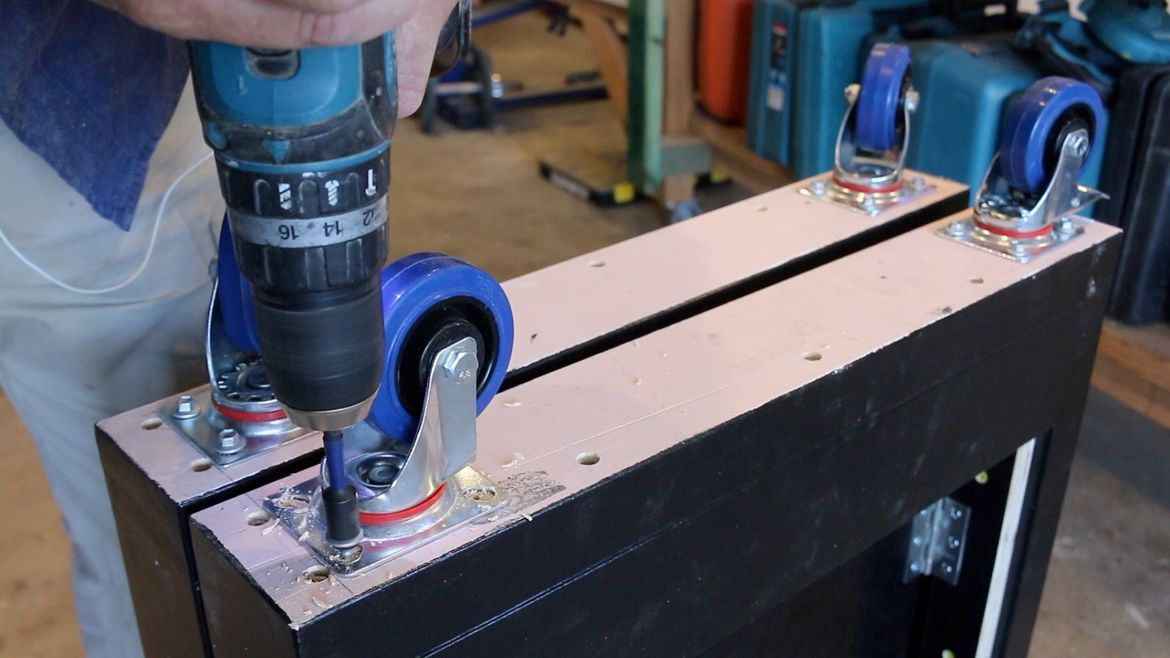

8/10Attach the wheels to the underside of the end frames. One word of advice is to offset the wheels. As you can see in the photo, l originally didn't do that causing the wheels to occasionally clash when when wheeling it away which was a little annoying. I have since offset the wheels and it now works a lot better 👍

Step 9

9/10As you can see it folds up to a very slim and tidy 180mm which is small enough to even store inside a cupboard when not in use!

Step 10

10/10And here is the finished product!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Space-saving folding workbench

Don't fight the urge Dave.....you know you want to go 😂

- « Previous

-

- 1

- 2

- Next »

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects