The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: General wooden shed build questions

How to build a wooden shed?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to build a wooden shed?

Hi all, I am about to build a small wooden garden storage shed (3m wide x 2.4m deep) on a gravel base. I have been soaking up tutorials, reading the various excellent posts on this forum and on wooden framing and feel fairly confident about most stages but there are a few grey areas that I would love the community guidance on (and will likely lean on you for tips along the way!).

I previously prepped the ground and laid a gravel pad. The plan is to put 2 x 6 treated joists directly into TuffBlocks as the base of the shed and build on top of that.

So my questions are:

Flooring

1. I am looking at treated yellow tongue STRUCAflor is this suitable or is there a better alternative? Treated plywood looks very expensive but I don't mind paying if it means increased longevity.

2. Silly question, but given the fact an exposed tongue in these boards will be at one edge of the shed. Do you just cut these off or just fill the gap with sealant?

Walls

1. What options do I have for external wooden wall panels? I would like something that looks nicer than particleboard or OSB. Is there an outdoor option of these slotted panels? I guess I could use weatherboards but curious at alternatives.

2. Should I use building wrap?

Roofing

1. What are my options here? Just colourbond sheets? If yes, should I still put a plywood/OSB roof on and apply the colourbond to that or just attach it straight to the rafters? I assume I would have lots of gaps if I attach directly to the rafters.

2. If colourbond is the way to go, I'm curious to know what you use so that you don't just have sharp raw edges and what to use for the apex of a pitched roof?

Fasteners

I'm going to use screws instead of nails for framing (Personal preference, if I had a nailgun it might be different 😄). So I don't want to have to pre-drill or anything. What gauge is best, 12g? or thicker? Something like these Buildex RapidDrive Treated Pine Screws 12g x 75mm?

I think that's all I need to know at the moment, once I have these answers I can make my materials order and get stuck in!

Thanks so much

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: General wooden shed build questions

Hi @mikebarker,

Structural flooring would be suitable for your project. You might like to paint the underside with bitumen paint for additional moisture protection. From my experience, marine-grade plywood does not cope well in moist conditions, despite the name. It's great for marine environments when it's entirely encapsulated with epoxy resin.

Instead of having the groove exposed, I'd just trim the edge of the board off or add an aluminium angle to cover the edge.

You have exterior fibre cement cladding sheets like the BGC Fibre Cement 2450 x 1200 x 9mm Duragroove Smooth Narrow Fibre Cement Sheet - 2450mm that will give you a similar look. You should most definitely use sarking.

Typically, you would attach the roof sheeting to the rafters. What sort of gaps were you envisaging? There is a variety of different flashings to cover gaps around the sides and various other places. Corrugated roofing is likely the most cost-effective and popular solution.

Edges are normally left as is, and corners can be rounded with aviation snips, but flashings are used to cover most edges, so there should be too many left exposed. Ridge flashing is used on the apex of a roof.

I'd be going for the 100mm instead, depending on the size timbers you're using. Say you're using 45mm studs, with the 75mm screw that only leaves you with 30mm in the joining timber.

Please let me know if you have further questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: General wooden shed build questions

Hi @MitchellMc, Superb advice as always! That's really helpful.

Wow, so cement board is the only external type of that kind of siding? I wonder if the materials I am thinking of are just meant to be sealed/painted to be able to handle the outdoors. Is cement board hard to screw into (Need special screws)? And I assume cutting it is tricky too? Is there a valid cheaper option?

Ok cool, I'll just attach the roof sheeting straight to the rafters. I thought there would be a gap on the edge unless the groove of the corrugation of the roof sheeting lines up perfectly with the rafters and noted on the screw size.

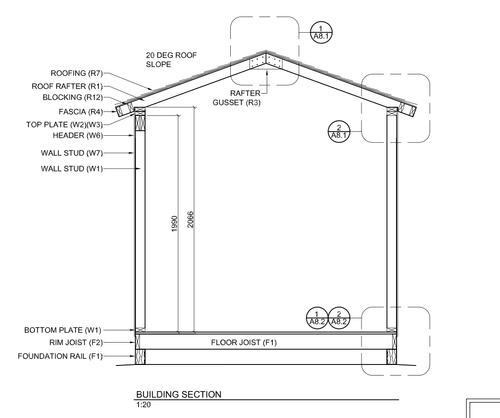

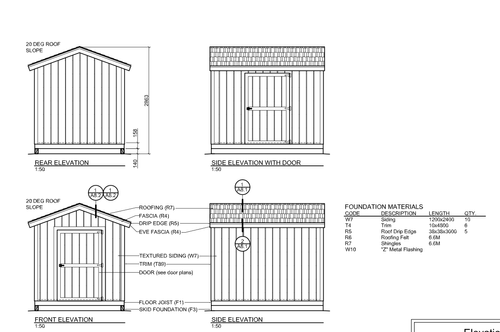

In case it's helpful, this is the design I'll likely be following, which shows the edging details, but this is based on an OSB roof with shingles which I'm pretty sure no one uses in Australia. I just need to make sure this will still work for using roofing sheets, I'm sure it'll be fine.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: General wooden shed build questions

Hi @mikebarker,

Cement board is not the only type of siding available. However, those Duragroove boards are the closest example I can think of that match the internal Easycraft panels you've referenced. There are fibre cement screws, but typically clouts would be used for fixing. Cutting is not particularly tricky and can be done with a score and snap knife or sheet cutter.

Sorry, I just realised you asked about external timber wall cladding options. There are some options available, but per square meter would come in above the cost of cement sheeting. I guess it comes down to whether you'll be painting the walls or if you want a natural timber finish.

That design looks like it would work fine with corrugated roofing sheets.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: General wooden shed build questions

@MitchellMc Thanks for the tips on handling those sheets, not as bad as I was thinking.

So even a weatherboard solution will cost more than the concrete siding? Or is that just categorised as "timber cladding"? I see there are a lot of options for weatherboards, I had no idea the cost of the walls was going to be more than the rest of the shed combined 😄

Forgetting my initial cladding example, what would you deem the most budget-friendly-but-not-totally-awful option for walls? Regarding the final look/finish, I'm open to ideas.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: General wooden shed build questions

Hello @mikebarker

Looking at the fibre cement cladding sheets, I'm afraid you are absolute right when you say that the cost of the walls is more than rest of the shed combined. I propose looking at BGC Durasheet 3000 x 900 x 4.5mm Fibre Cement Cladding 2.70sqm depending on the height of your shed you would conservatively need a minimum of two sheets per wall.

You can get creative by putting timber moulding strips on the cladding to break up the flat surface look of the sheets. When you paint the shed, I suggest painting the moulding in a contrasting colour so that the shed will have a nice look to it.

Another method to get creative is to paint lines on the cladding sheet to mimic the look of timber cladding.

Let me call on our experienced members @Dave-1 and @TedBear for their recommendations.

If you need further assistance, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: General wooden shed build questions

Evening @mikebarker

![]() I know that shocked feeling! I remember working out the tin for my deck roofing and what it would cost... Almost fell off my seat and thats a decade ago! Fast forward today and I think since we dont usually work in an area it always catches us unawares.

I know that shocked feeling! I remember working out the tin for my deck roofing and what it would cost... Almost fell off my seat and thats a decade ago! Fast forward today and I think since we dont usually work in an area it always catches us unawares.

A couple of questions for you of course ![]()

Are you going with that style rafter from your pics above? I have never used it myself and the style and weight of your roofing needs to match that brackets strength.

What are you using the shed for? (I thought of the clear Suntuf boxed panels Suntuf Sunlite 8mm x 610mm x 3.0m Clear Twinwall Polycarbonate Roofing ) It just depends on how secure and viewable you mind your shed.

Instead of the weatherboards and there are some nice ones that Id choose straight up ![]() How about something like Fielders 1800mm 0.42mm BMT Zincalume Steel S-Rib Corrugated Steel Cladding. You could stand it vertical or horizontal depending, you could also have the non viewable side of the shed as the corrugated style and the facing side as the weatherboard?

How about something like Fielders 1800mm 0.42mm BMT Zincalume Steel S-Rib Corrugated Steel Cladding. You could stand it vertical or horizontal depending, you could also have the non viewable side of the shed as the corrugated style and the facing side as the weatherboard?

I really like the American/European style shingles with a tar sheeting under them, I have wondered if I would have a go doing the same one day ![]() Tho Id probably use trusses as they seem stronger (personal preference is all)

Tho Id probably use trusses as they seem stronger (personal preference is all)

I also like the idea of the Hardie sheeting and then as @EricL suggested put some timber molding strips to seal the joins or form a pattern. I just used a sheet of it for a backing of a bench and at $16.50 for a 600mm by 2.4m length I was surprised at the price. Maybe by a sheet (it fitted in my car ![]() ) and have a go at securing it to some timber, that way you can get a feel of how to use it. (I cheated and didnt put a screw through my piece but clamped it)

) and have a go at securing it to some timber, that way you can get a feel of how to use it. (I cheated and didnt put a screw through my piece but clamped it)

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: General wooden shed build questions

@EricL that is a great cost-saving idea, thanks for that. Definitely food for thought.

@Dave-1 ha yeah, I genuinely thought a DIY shed build, including the groundwork, would come in under $1000 😆 I'm slowly realising the real cost of things.

Answering your Q's:

1. Are you going with that style rafter from your pics above? - That is the plan and I think it'll be fine. The design calls for OSB with shingles so some colourbond or similar will be fine.

2. What are you using the shed for? - A storage shed for gardening gear, bikes and some tools. I think adding a clear sheet on the roof would be great, but I wouldn't want the entire contents exposed to the sun that way. You can get clear corrugated panels can't you?

3. Steel cladding - it's not a bad shout. If I did it I'd do the full thing rather than certain sides, I think it would bother me it being mismatched but that would be a nice cost saver.

4. All the designs I see use shingles for the roof but as far as I could tell they aren't used in Australia? I assumed due to the heat.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: General wooden shed build questions

Afternoon @mikebarker

Yeah clearish suntuff sheets are available ![]() And yeah I wouldnt want people to see that stuff inside

And yeah I wouldnt want people to see that stuff inside ![]()

hahaha Id have to do the lot the same style as well, it would drive me nuts but I am not he one paying for it so was going easy ![]()

About the shingles, not sure why we dont have them here, you would think the hard wood split would have been for sure?

I have seen videos of people using soft drink cans cut and opened up then layered like the shingles. Maybe because corrugated iron has been around for years (My grandfather "acquired" his from the local power station when they were building their house. Maybe because it was produced so prolifically that was the preferred?

Cant wait to see how you go if you use timber shingles ![]() I think it would look pretty slick!

I think it would look pretty slick!

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: General wooden shed build questions

Evening @mikebarker

I saw shingles today! Slate! lol I went up the blue mountains West of Sydney for a drive and cruising along I saw these funky looking tiles! ![]() Couldn't take a pic as I was driving and no way did I really have time

Couldn't take a pic as I was driving and no way did I really have time ![]() They do exist but wonder why they were never taken up so much?

They do exist but wonder why they were never taken up so much?

Dave

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.