- Bunnings Workshop

- >

- Discussion

- >

- Bathroom and Laundry

- >

- Re: Tap spindle too short

How to extend a wall tap spindle?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to extend a wall tap spindle?

I have recently brought new mondella pin lever 1/4 turn ceramic taps - https://www.bunnings.com.au/mondella-black-resonance-pin-lever-wall-top-assembly_p5004187

However once installed we don't have enough spindle left to properly attach the cover plate, tap handle and secure the screw so that the tap handle doesn't fall off we are only maybe 2/3mm off it working (the handle can be attached without the cover plate).

We tried to use these spindle extenders but they don't reach to the seat at the back of the tap, so the water constantly flows. https://www.bunnings.com.au/kinetic-28mm-ceramic-disc-spindle-extender-2-pack_p5050142

Does anyone have any ideas of what we could use? I cant find any spindle extenders or longer spindles that are the correct style for these taps.

I need these but in a different style? https://www.bunnings.com.au/kinetic-20-25mm-spindle-top-extender-4-pack_p5050144

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Tap spindle too short

I had a similar issue with one of my shower taps ... I got these and it worked a treat! Worth asking at your local Bunnings if they'd work with your taps.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Tap spindle too short

Hi @Samviv,

It's great to see @DIYMum has offered a solution that worked for them.

I just wanted to check that you adjusted the depth on the spindle locking nut when changing them from the wall to the extenders. It's commonplace that even without extenders, people experience installing 1/4 turn ceramic disk spindles and the water not being shut off, myself included. You might be well aware of this, but it also exhibits the same issues you are experiencing here, and we need to rule it out before looking for other options. Even though the spindles cut the water off when installed in the wall, it doesn't mean they'll cut the water off when installed in the extenders. So my question is, are the extenders not reaching the seat of the wall fitting, or are the spindles not reaching the seat of the extender? Both of these scenarios prevent the water from being shut off.

When installing the spindles into the extenders, did you re-adjust the copper locking nut to suit their new depth or just swap them over? If you adjusted them, we can move on. If not, undo the copper nut on the threaded section of the spindle's body. Screw the spindle into the extender until it mates with the seat. Only then do the nut on the body up to lock in place and nip it up tight with a tap spanner.

I apologise if you are already aware of this, but it's worth mentioning as it's a common issue. It had me stumped for a good half an hour as I'd only ever installed traditional valve taps before where their height doesn't need to be adjusted.

Either way, let me know what you've tried, and we can work on a solution.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Tap spindle too short

Hi @Samviv,

We're having this exact same issue with the very same taps. Did you ever find a resolution to bring out the spindle far enough to get the cover flange and tap both fitted?

@MitchellMc

Would fitting something like this inbetween the breech outlet and spindle work in order to bring out the spindle from the wall - hence exposing more threads or wouldn't it work as it'd also mean the spindle base would no longer be against the seat of the breech?

https://www.bunnings.com.au/kinetic-20mm-brass-male-female-threaded-adaptor_p4700205

We tried the https://www.bunnings.com.au/kinetic-28mm-ceramic-disc-spindle-extender-2-pack_p5050142 but they then extended the spindle out too far to the point the cover flange wouldn't sit flush against the wall. If only they came in a shorter size than 28mm! I know you can purchase 'trouble domes' to fill in the gap but we would prefer to not have those for a cleaner install. When we also fitted this, it worked fine for the first 20 minutes during the shower then it started to squeal (usually a sign of high water pressure) then after the shower and water had been off for say 5 minutes - there was a 'pop' followed by the hot water coming on despite the tap being off so we had to remove it. What would be the cause of this if you happen to know?

If we can't figure out something then we will probably just have to remove them and look for something else with a longer spindle out of the box rather than dealing with extenders and extensions of sorts.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Tap spindle too short

Welcome to the Bunnings Workshop community @Vic477. It's great to have you join us, and many thanks for your question about extending taps.

I don't believe that fitting would work. Ezy-Fix does some similar extenders, but they are only suited to the old jumper style valves. I've checked around, and I can't find any extenders suitable for ceramic disc taps that are less than 28mm. It seems to be a bit of a standard size.

You could try adding these Kinetic 20 - 25mm Spindle Top Extenders. I suspect they might induce a bit of a gap in between the tap handle and cover plate. That would likely look better than a gap between the cover plate and wall.

In regards to the hot water coming on, I'm not quite sure. If the spindles were installed correctly, the only thing I can think of would be that the O-ring that mates with the breech or the ceramic disc failed. I can't imagine why this would have happened and haven't heard of it before, but that's the only reason I can think of for water to be bypassing the valve.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Tap spindle too short

@Vic477 We did end up solving the issue although I’m not sure Bunnings would recommend doing this.

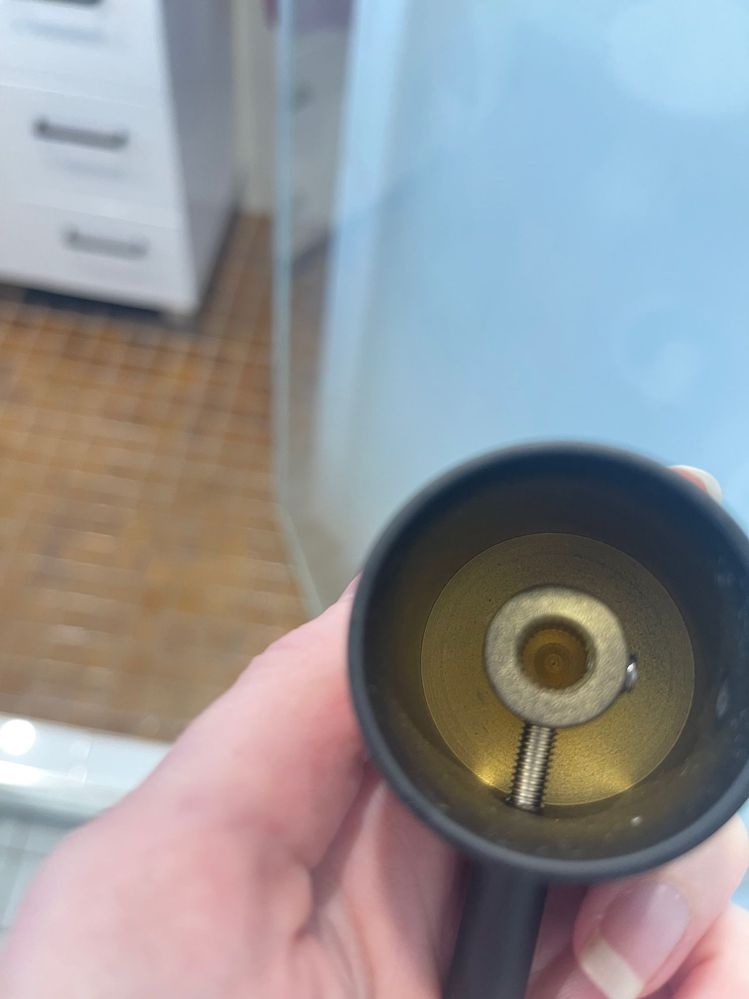

We ended up having to drill a small hole into the spindle end. Added a screw and then wrapped copper wiring around the screw so it was the same width as the spindle itself. You wouldn’t be able to do that if the handle doesn’t catch on the spindle at all. (We we’re ok because there was enough overlap for the tap to still function. Like the handle worked without adding the screw it just wouldn’t stay on the spindle.)

Then we did the nut up on the handle. So far it’s held good!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Tap spindle too short

Thanks @Samviv!

I don't suppose it'd be too much trouble to take a photo of the screw you fitted to the end of the spindle when you have some time just so we have a better idea as we could try that before we opt on removing it all in turn for another brand of spindles?

We have, what feels like, 3-5mm of overlap from the spindle with the cover flange fitted so think this should be enough for the splines to catch (hopefully).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Tap spindle too short

Hello @Vic477

I'm sorry to hear that your shower handle issue has not been resolved. I recommend using Kinetic 20 - 25mm Spindle Top Extender - 4 Pack. It will be necessary to modify the sides of the extenders using Craftright 9 Piece File Set in order for the Mondella handle to fit. Please make sure to file evenly on all sides of the top extender. Once you have it at the right size, please make sure that the grub screw is secure to prevent the handle from slipping. I've placed a quick sketch at the bottom for you to see, please tell me what you think.

Please keep us updated with your progress, we look forward to seeing your shower set assembled and ready for use.

If you need further assistance, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Tap spindle too short

Hi @EricL,

Thanks for the idea. I did see these but didn't think they'd suit given the Modella's specific spline pattern on the spindle as in order to fit those spindle extenders to the end of the original spindle - it'd involve also filing down the splines on the spindle correct?

I also assume those spindle extenders are held in place by another grub screw given the allen key in the photos?

Lastly, even at 20mm with the shorter extender, it may be too long of an extension to the point that the handle would then stick out further than ideal and result in not being identical to the other tap (I should've mentioned it's only one side of the breech that's recessed and causing this issue, the other side is fine).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Tap spindle too short

Hi @Vic477

There's no need to file down the splines on the spindle unless it doesn't fit. If you do have to file them down, it will not be a great deal as the top extenders are built for generic spindles. Yes, you're correct they are held in place with a grub screw. The best part about this top extender is that it is made out of brass. You can trim it down using a hack saw. Please note, you don't want to trim too much off otherwise it will become too short and the grub screw on the handle will not be able to lock on to the top extender.

The tap handle spline receiver is actually quite deep. I suggest filing down the top extender as best you can and then testing for height. Your other option is to exchange the set for a traditional one with rubber jumper valves. If you decide to give it a go, please let us know.

Eric

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.