The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: Outside timber lounge with wheels

Outside timber lounge with wheels

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Outside timber lounge with wheels

I have wanted a replacement for my old timber sunlounge. It had been too many years in the sun and one day when I dropped myself on the timber frame I hearad a "Craaaaak" The old joined timbers had spit... Noooo not because of the weight on it ![]() But it did feel that way! Anyway I wanted a solid replacement that I could move around depending on the weather and/or parties that could be on.

But it did feel that way! Anyway I wanted a solid replacement that I could move around depending on the weather and/or parties that could be on.

Materials

10 of Pine Structual Treated H3 90*45mm by 2.4m

4 of Castor Metal Ctr Brake Move it 100mm Black Rubber

Decking screws 45mm (left over box of 1000)

Yellow Gum decking 90 * 18 by 2.4m

Merabu decking 90 *18 by 2.4m

Natural clear Timber oil Cabots (leftover 1/5th of the can)

Tools

Ozito torqued battery drill

Makita powered drill

Nakita drop saw

Countersink Bit

Ratchet Staps

Timber spacers

Steps

Step 1

I had finished my Bench ( Outside bench ) for the pool/deck area and had the leftover yellow gum slats, but not enough to do the seat and backrest. No matter how I configured it I couldnt create a more covered seat. I decided to go with Merabu slats and tried alternate slats between the Yellow Gum then Merabu, but in the end the backrest looked great as Yellowgum and the seat which will be covered with a cushion one day are Merabu Slats.

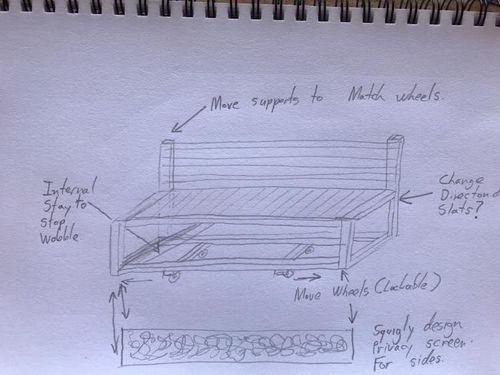

This was my first sketch when I was nutting out ideas and trying to maximise the use of the yellowgum timber slats

Half the project is finding the information out, I know its online but seeing it and then slotting it together certainly helps me out in visualising the problems.

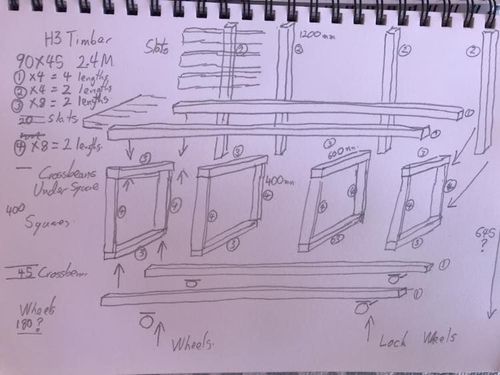

An exploding diagram to show how the bits should come together.

All the slats I had left over from the bench... Tried so hard to figure out wider spaces between slats ect but in the end using two colurs of timber worked really nicely

Have to say I love my dropsaw, it really allows me to do all sorts of nicer cuts.

So the bits are not screwed together at this point as I was trying to figure the height of the base of the seat. I was checking if I could sit at it and not have that pain under the knees if its the wrong height.

I am glad I did a test as the original height I had in my head would have been way to tall.

I made four of the frames up and then attached rails to them. I had to switch the rails around from on top to underneath once I worked out how the slats would run.

It wasnt quiet square so I stood it on end and loosened the screws off. It came together nicely at that point.

You can see the rails under the frame, looking at the picture now I realise I could have done away with these top two rails and just relied on the seat slats. Tho I think I like knowing that the frame is solid no matter what.

Resting on the wheels so I can get the placing right as I dont want it to be too far apart with the wheelbase. Also testing out the backrest height. It will be double use as a windbreak in the winds if I spin it around so its 90 degrees from where it is now.

Step 2

This project really didnt take too long to complete, from memory is around a week at a couple of hours every afternoon.

Backing posts secured.

Playing with the perspective and size of the seat. I didnt want it to overpower the area.

Slats just resting at this point. I was going to see if I could get some more yellow gum but the shortesy lengths were 4m and I didnt want wastage but wanted it to look good. Quandry plus!

I take photos, lots of photos as I know i will be somewhere trying to recall the information. This was for the height of the backrest and trying to work out the gaps between the slats...

I fluked out! I got a discount on these Merbau slats as they were very heavily cystalised.

I thought Id take a chance cleaning them as I could scratch the crystals off with my fingernail...

Spatula worked a dream, It was a mid 30deg day and it was hot!

The red ran like crazy!

After they dried. They had come up really nice.

Playing with patterns, nothing fixed at this point. I really wanted to make the most of what I had.

Bingo! found the most appealing colouring match, yellowgum back and merbau seat. Plus one extra piece for just under the lip of the seat!

Ratchets are my friend, The merbau slats had bends in them. I use the ratchets to straighten them out and then screw them down.

Showing how I use the ratchets to pull the bend in line.

This is to pull the seat slats into line. It works but sometimes figuring out how to run the webbing so that there is only stress on the right part is difficult.

Wastage ![]() The 2.4m lengths were 2.4m's long

The 2.4m lengths were 2.4m's long ![]()

Seat done! Tomorrow the backrest!

I want the chair to be able to breath, I also reused the spacers I had for the privacy screen (to the left of the seat) so it matched in spacing.

Trying to figure out what to use as a kickboard...

I used this for a kickboard under my bench. It may be too much under the seat as well... Thinking..

Sighting the height it would go to. I really had started to like the idea of a windbreak so I could enjoy the area even in winter. In winter and Autumn the wind cuts straight across the deck to the pool so a high backrest would be handy to have.

Soap on the screws ![]() Makes them go in easier. also showing my spacers. So this is pic one

Makes them go in easier. also showing my spacers. So this is pic one

Pic two

Pic three, this is the one piece of timber that really had a bananna bend to it. Nerver fear the ratchets saved the day ![]() I just slowly worked my way along. It was handy having four posts to the backrest while doing this so the force was distrubuted over a larger distance.

I just slowly worked my way along. It was handy having four posts to the backrest while doing this so the force was distrubuted over a larger distance.

Standing back you can see the bananna...

Step 3

Somedays I am just thankful to have a nice spot to be working in ![]()

Back to continuing the backrest slats. I left a gap down the bottom of both the backrest and the seat slats as It was never going to be used (The part in the corner between the backrest and seat)

Trying to determine if I should go higher or trim the posts...

Posts trimmed! I decided the backrest was high enough.

All done bar the wheels and oiling of the timber before it rains.

Final wheel spacing decided. I didnt want the wheels further towards the ends as then potentially someone running and jumping onto the seat may make it flex in the middle (well not really with the amount of timber in it lol ) but that was the thinking behind the spacing.

Seat lyng down on the job. Surprisngly not heavy. I tilted it by myself and stoood it back up with no issues.

So this is the piece that sits below the lip of the seat. It had a huge bananna bend to it and I had very limited fix points for the ratchet. After 40mins of trying it this way, with levers here and there I step back looked at it, shook my head at making something more complicated then it needed to be and used a chock and taped it into place and that forced the bend level so I could screw it in.

Wheels all done, the last of the skirt is done for now (unless I find another yellow gum piece or two of 2.4m yellow gum ![]() )

)

Wastage from the bench and seat projects...

Offcuts ![]()

Back of the seat, I could put a flat board on the base under the seat slats to store things underneath but like the idea of free airflow around and under the seat.

In the "Windbreak" configuration

With the bench (tho skirt wasnt dont at this point)

Main place the seat will live. Pretty happy with how it turned out and very surpprised at how easy it moves and wheels lock if needed.

Whoops, almost forgot to oil it!

Very fidly but considering its outside I thought better to make sure then not..

I have just redone the deck (sanded it back from grey and then re-oiled it) so didnt want oil drops on the newly done deck. (the maintanence of the deck is another project yet to be posted )

Oiled everywhere I could reach.

I was getting worried I would not have enough oil left to do the job....

Really changed the tint of the timber.

Made it! ![]() Nothing left in the tin and all the oiled surfaces are done!

Nothing left in the tin and all the oiled surfaces are done!

Both the Bench, now with skirt and the seat are completed. Next stage is the bessa block wall of the pool.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Outside timber lounge with wheels

Wow, @Dave-1! What a super project that looks sensational.

The amount of detail you've included will surely assist any of our members wanting to replicate this timber lounge. I love that you included the wheels, as it will make it a breeze to re-locate if needed.

Many thanks for sharing your project, as I trust it will inspire many community members to give it a go themselves.

Well done!

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Outside timber lounge with wheels

Thank you @MitchellMc

![]() I really had fun doing building it and think the materials cost around $300 (Maybe a little higher) but will add them all up later and put them in here

I really had fun doing building it and think the materials cost around $300 (Maybe a little higher) but will add them all up later and put them in here ![]()

Dave

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.