The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: Raised Cubby House

How to raise a cubby house off the ground for a sandpit beneath?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to raise a cubby house off the ground for a sandpit beneath?

Hello,

Have purchased a cubby house and would like to raise it off the ground to a height of about 1m as I would like to incorporate a sandpit beneath. Have a few ideas in mind but not exactly sure which approach would be most ideal and wanting some advice/recommendations. The cubby house is 2.7m x 2.5m. My intention is to have 9 posts dug at a dept of 600mm and at a width of 180mm using 90mm x 90mm H4 treated pine posts. To build the subfloor I was going to have two bearers and about 5-6 joists. Am not exactly sure which way the bearers should run and how they should attach to the posts.

Also how should the joists be attached to the bearers, just nailed in on an angle, bugle screws or joist hangers?

And what would the recommended size of the bearers and joists be?

Tagging @MitchellMc for ideas.

Picture below is the idea that I have.

Thanks in advance

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Raised Cubby House

Thanks @MitchellMc I'll go 100 x 100mm.

Also I dug out 200mm diameter holes at a depth of 600mm. Is this sufficient ? Reading online suggests the diameter should be 300mm but others suggest you just double the post size to get your hole size. Paralysed by reading too much information.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Raised Cubby House

I'd go with 300mm @globetrotter. Doubling your post size wouldn't be sufficient unless it was in a non-load-bearing application. For instance, I was always taught that even a letterbox with a 50mm post should have a concrete footer 300 x 300 x 300mm. You've got plenty of depth, but I'd like to see the width more than 200mm.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Raised Cubby House

@MitchellMc I'm still going with the cubby house. Posts are in, cubby house floor and walls are assembled. I need to complete the decking, roof and deck railings. I was wondering what you would suggest for the rail banisters? I was looking for something narrow and obviously treated pine. The smallest I could see was 70x35mm which I think I would need to rip in half otherwise it would look a bit too chunky. Would you say that's my best bet as I couldn't see anything else suitable. Thanks in advance.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Raised Cubby House

It's great to hear that you're making excellent progress with the cubby house. Have you thought about using Ekodeck Panels? If you rip cut them you'll be able to get three strips of 43.5mm x 23mm conservatively. It's inorganic, will not need to be painted or maintained and the best part is that it does not contain any chemical preservatives.

I'm sure @MitchellMc will let us know if he has additional advice.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Raised Cubby House

Ripping the 70 x 35mm timber down is likely a good option @globetrotter. We do also have a range of H3 treated mouldings and LOSP FJ primed timber if you're planning on painting.

Feel free to post some update images if you'd like. I trust our members would love to follow along.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Raised Cubby House

I'll go with ripping 70x35 to keep costs down. I think I underestimated the cost of this project.

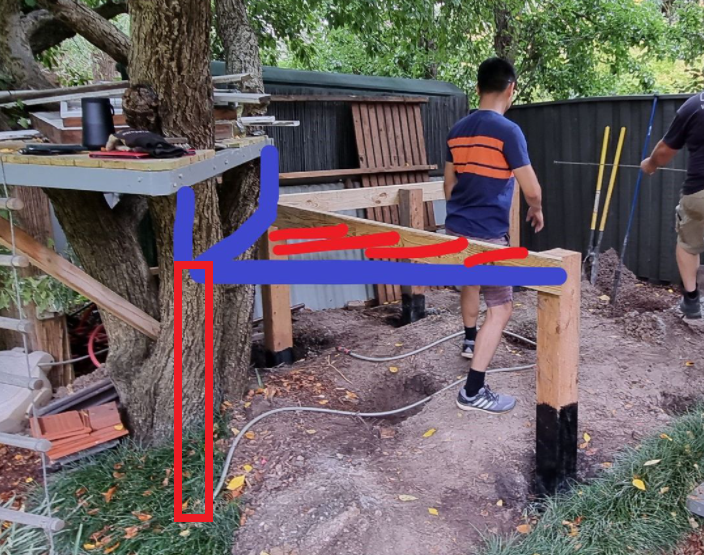

Some pictures for your to see my progress. A few errors and struggles along the way. Lots of tree roots meant digging the holes wasn't too easy. Errors in the base isn't 100% square but I managed to get it to work.

One question I wanted to extend the verandah to connect to the tree and the landing that is already on the tree. What I had in mind was to triangulate the verandah and create a step up to the landing on the tree.

Have a look at my concept diagram and let me know if you agree with this idea.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Raised Cubby House

Oh, wow @globetrotter! Amazing effort! That's looking wonderful.

We might no longer be friends, but I'd like to see an additional post installed for your triangular verandah. However, it should be fine if that corner can be fixed adequately to the frame above.

I can't wait to see this finished; it's a very inspiring project. Please keep us updated.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Raised Cubby House

Thanks - luckily it looks great from a distance :-). Closer inspection might find flaws.

@MitchellMc umm you are leaving the said organisation?

I think I'm over digging post holes :-). I'll connect a post from the frame above to the new verandah.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.