The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: How to fix posts at 90º to horizonta...

How to fix posts at 90º to horizontal when surface is sloping?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to fix posts at 90º to horizontal when surface is sloping?

Yesterday I erected the poles for an outdoor clothesline.

Each post has a flat base plate with four holes for securing to the base strata

I am fastening to a concrete path to which the clothes line will be parallel

The path is level along its width and length but slopes down from its high to low side, all along its length

I drilled appropriate holes for dynabolts & erected the posts and cross bar

Looked at my handiwork and all seemed good - the posts were vertical looking head on in relation to the length

However - me, very stupidly, had not accounted for the slope of the path from side to side

Accordingly, although I'd made sure the posts were at 90º to the concrete in each plane, they were now not vertical in the back to front plane but actually leaning forward.

...

After berating myself with a few curses, I put my tools away and took my dog for a walk. I get depressed easily for it seems that whenever I attempt anything, I mess it up. I have zero skills or experience as a tradesman but as a below-the-poverty line pensioner, have to do things myself because I can't afford trade rates. No - I'm not seeking sympathy just explaining why I didin't do the obvious and have someone install the washing line for me.

...

This morning I have dismantled the clothes posts and drilled and cold chiselled the dynabolts out of the ground.

I had decided that I would cut back the concrete where the posts go so that it was level. I tried an angle grinder with a concrete wheel but it was hopeless - i.e. I couldn't make it do the job. So I tried a cold chisel but that seemed too laborious and just as difficult.

So, I'm back where I started but with some untidy looking holes where the original bolts were.

I need to re-erect the clothes line posts but ensure that I have them vertical to a 180 horizontal base, not the angle of the concrete path.

My ideas are:

- Use shims - however as the slope is even I'm not sure that this would work without more chiselling or something

- Use some concrete or similar to build rectangular rises on the path to a level height where the post bases will fit - but then how do I ensure that the concrete is even and at 180º on its surface? Should I make some sort of miniature form work or something - seems as though it would be very fiddly

- ?

If anyone can help with suggestions of a process that would , preferably, be relatively quick and simple and within the capacity of an imbecile, I would be very appreciative of your advice.

Thanks.

Solved! See most helpful response

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix posts at 90º to horizontal when surface is sloping?

Hey @nonsibicunctis don't stress about this one it's not a hard fix and very similar to what we used to do installing car park lighting just on a smaller scale.

So what you want to use instead of dynabolts is dropins. Now a quick search and I found a 50 back in passified zinc but I'm sure they come in hot dip galvanised.

Grab some the correct drill out size, you will also need the correct size knock in tool as per below.

Install your 4 dropins then with a grinder or hack saw cut 4 desired over size lengths of the threaded rod, you may need need to file the end to start the thread check with one of the nuts.

Then once the rods are good thread them into the dropins.

On the side that needs leveling up thread on a nut then a washer on the other side nothing.

Then install your post and thread on 4 washers and 4 nuts.

Don't do them up tight yet.

With a level placed on the post check either side you can now adjust the nuts below the plate to level up the post. Once it is all level tighten all nuts up.

With the gap under the plate you can pack it with a mortar mix and finish with a trowel for neatness.

This is a basic version of street and carpark lighting

Hope that helps let me know.

Carl

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix posts at 90º to horizontal when surface is sloping?

Thank you for your very prompt response and your advice. It seems to certainly be a way to go but perhaps a little more expensive than I'd like. - I mean no disrespect, it may turn out to be the best and cheapest alternative.

I am very grateful for you very clear explanation and an alternative of which I was not at all aware.

Thanks again,

roger

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix posts at 90º to horizontal when surface is sloping?

Hey @nonsibicunctis there maybe smaller packets of the dropins available to bring the price down.

Here is an alternate with an expansion anchor.

https://www.bunnings.com.au/macsim-m10-yellow-zinc-medium-duty-macloc-anchor-10-jar_p0121759

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix posts at 90º to horizontal when surface is sloping?

Good afternoon @nonsibicunctis

Sorry things aren't going as planned - don't get too disheartened.

"If anyone can help with suggestions"

I can only describe what I believe I would do in your situation - so it's just another suggestion. And I too am always on a strict budget.

I'm glad you got the dynabolts out.

I no longer use them in concrete - I always use concrete bolts. Easy to insert and remove.

I would use them to re-attach the bases to the concrete. You will need to drill larger holes to suit the concrete bolts.

Once the bases are back in - my understanding (I could be wrong) is the two poles are misaligned.

Now you need to "call a friend" who can weld.

Cut the square metal poles close to the base (possibly three sides) and bend them to the correct position you want - it's a lot easier than it sounds.

Weld the sides into place.

You can do this many times - that's the great thing about metal.

I have a clothes line which I did the above procedure on - it's not pretty, but it works.

Anyway it's just another suggestion. The best of luck to you!

By the way - how did you get on with your handrail?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix posts at 90º to horizontal when surface is sloping?

Thank you for your suggestion. I do appreciate it.

I have some concrete screws but have never used them. These are tapered. Is this the same as a concrete bolt? How do I know what size hole to drill? The screws I have because they have a taper, would not have anything to hold onto if I drill a hole of the widest circumference. Your illustration seems to show. a bolt which is parallel along it's length. However, surely the thread still needs to grip so the hole would have to be less than the circumference of the bolt with thread, wouldn't it?

The actual posts are fine. They are true to the bases. The problem is that the concrete path to which I want to attach them actually slopes. From what I've read so far and what I know of the job, I think that my best bet is to use some shims to pack the lower end and bring it in line with the higher one, or to build a level (180º) platform for each pole. I'm only talking of about 1cm of drop in about 15cm of length from back to front of each pole base.

Thanks anyway for taking an interest and bothering to help. I still haven't done the railings. I'm slow. I have no friends or family, save for my best friend Lennie, my Belgian Shepherd. Unfortunately, he only talks about female dog and nuisance little dogs who think that they're big. He likes to try and hump me when I'm working and bend over but other than that, takes no interest in the jobs. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix posts at 90º to horizontal when surface is sloping?

Hi @nonsibicunctis,

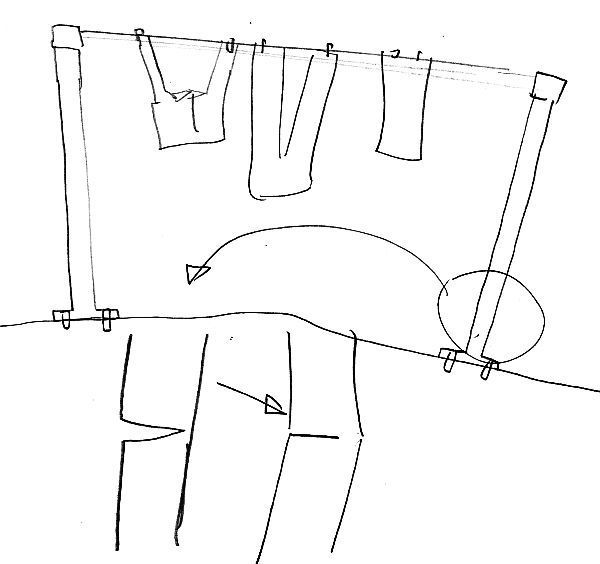

Effectively what you need to do is on the upper side of the slope is have the flange on the ground and then make up any difference on the lower side of the slope, in both planes.

Could be frontwards (ie down the slope)backwards or to either side.

Easiest way to do this from the start, is to fit your start post and the end post and run a tensioned string-line between the two, that will give you your lateral mark as to where the posts in between should be, they should just touch the string-line, but you will still need to get the vertical posts, vertical.

It's also handy for doing fences as well.

Let us know how you get on.

Cheers,

Mike T.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix posts at 90º to horizontal when surface is sloping?

It's great that you've received excellent suggestions from @CSParnell and @Noyade. Just to add to the recommendations made, I propose using galvanized washers threaded through the bolt to level out the post. Since it is just for an outdoor clothesline the majority of the force exerted on the post will be horizontal. What's important is that the post lines up with the other post on the other side so that the washing lines line up.

If you have any other questions we can help with, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix posts at 90º to horizontal when surface is sloping?

Hi @nonsibicunctis,

If you're going to use fixings into concrete, I would suggest you use M10 x 120mm long Stainless Steel Dynabolts.

Use actual Stainless Dynabolts, yes they are a tad more expensive, but you only want to do the job once, galvanised or Japanned steel coating won't last outside, especially in contact with concrete.

They aren't tapered, you drill a 10mm hole with a masonry bit in a hammer drill, allow for the thickness of the flange on your mountings and set the Dynabolt into the hole, do up the bolt and you're done.

You could also use some Res-Q-Steel anti-seize paste on the Dynabolt threads if they need to be taken apart again.

Stainless steel, while it doesn't rust, has a habit of galling when the threads are in contact with moisture.

If you have any further questions as to what I'm on about, post a reply below, as I'd like to help you out.

Cheers,

Mike T.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to fix posts at 90º to horizontal when surface is sloping?

Hi again @nonsibicunctis

Sorry, clearly I'm not comprehending the wording above. I thought the issue was a sloped path that meant at least one pole was not vertical. Apologies.

"However, surely the thread still needs to grip so the hole would have to be less than the circumference of the bolt with thread, wouldn't it?"

Yes, once purchased the instructions will tell you what diameter masonry drill bit to use. Very little thread is required - because the medium is concrete. A socket set is the best way to drive them in. There is some initial resistance but once this is overcome they go in nicely. Sometimes I smear grease on the thread, especially if I'm considering removing them later. Always remember to drill deeper than the length of the bolt. I have destroyed a socket by not adhering to this law. 😔

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.