The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- How to build a small low-level deck for ...

How to build a small low-level deck for laundry door?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to build a small low-level deck for laundry door?

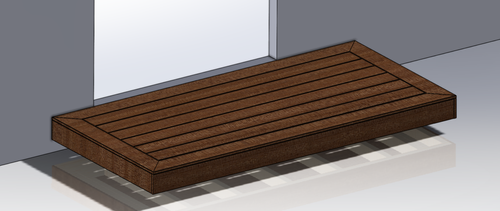

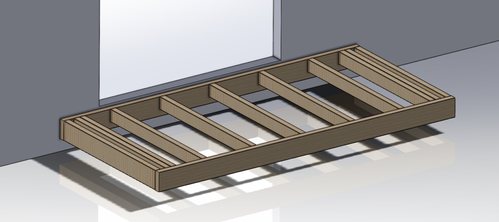

I'm working on a design for a small, low level deck for the laundry entrance on the side of my brick veneer house. I think I have the design of the frame mostly down pat, but had a few questions on some of the specifics.

Design:

- The size of the deck is 2400x1155. I wanted ~1200 and 1155 is the closest size with 140x19 deck panels and 5mm spacing

- 140x45 ledger board + bearer and outer joists (are they joists or a bearers?)

- 90x45x1050 joists approx 395mm center to center

- Doubled joists for picture framing

- 140x19 merbau decking panels

Questions:

- Do the outer joists/bearers need to be 140x45 or can I get away with 90x45s?

- Are dynabolts suitable to secure the ledger board to the brick veneer? If so, how many of what size? If not, how to I support the deck on that side?

- What should I use for posts on the outer edge? Currently planning to use 3x center fix post stirrups so the outer deck boards can neatly cover the bearers, but is this the best idea? It's currently just grass underneath and I'm happy to set some concrete.

- I am planning to use joist hangers, but how do I hang the doubled joists? There isn't a 90x90 joist hanger for sale. I could take a 90x200 hanger and cut it down, but that seems odd to need to do that. Am I missing something?

- Current the bottom edge of the deck will be about 150mm clear of the ground. Should I be designing the deck to come down another panel to be more flush with the ground? If so, how do I do that?

- Currently the area is grass and slopes away from the house slightly. I've seen a few posts mention drainage, but don't have a good understanding of that. Where can I get info on what is required?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small low level deck for laundry door

Welcome to the Bunnings Workshop community @rhino_aus. It's wonderful to have you join us, and many thanks for your question about constructing a deck.

90 x 45mm will be fine for the frame/outer joists. You just need to support it at no more than 1000mm spacings.

I believe construction codes stipulate that brick veneer is not suitable to have a ledger board attached to it. You'd need to have bolts that extend through it and connect to the timber behind the wall. Alternatively, you can have a free-floating deck and have it supported by post supports or pedestal feet at the wall.

For supports, I'd recommend using pedestal feet at the locations I've marked below. The pedestal feet can be placed on compacted ground, but I prefer to place them on a 300 x 300mm paver to distribute their load over a larger area.

For the double joists, I'd just screw through the outer frame and into their ends with landscape screws.

The height of the deck depends on the look you're going for. Having the posts/pedestal feet set back from the edge and no lower board will provide a really nice floating deck look. Personally, I'd leave the gap under the deck as not only will it look great, but it will allow plenty of airflow, which helps reduce the chance of timber decay.

For drainage under the deck, I recommend following this guide: How to build a deck. You'll see that I've placed weed matting and gravel under the deck to ensure good drainage and to stop water pooling.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small low level deck for laundry door

Thanks for the reply Mitchell!

Somewhat surprised about the ledger board because I've seen several projects that have used them. Is this a "do as I say, not as I do" type dealio? I think the idea of the pedestal feet seems quite easy. Are they bolted to the paver or secured to the ground in anyway? With nothing attaching the deck to the house, what stops it being "pushed" away? Just weight? For the feet, you've marked places that seem to indicate the joists. I thought the bearers are meant to take the load path through to the ground? Is this countered by just have lots more posts/feet than otherwise?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small low level deck for laundry door

Hi @rhino_aus,

Here's the relevant part of the construction code for you: the external wall supporting the deck or balcony is constructed of—

(i)

190 mm thick fully core-filled concrete masonry, reinforced with vertical N12 bars at not more than 600 mm centres; or

(ii)

steel framing complying with Part 3.4.2; or

(iii)

timber framing complying with Part 3.4.3; and

You'll note that brick veneer is not listed as a suitable wall type. The only way to comply is if a timber or steel frame behind the brick veneer could be used for attachment. You'd drill through the wall and the timber/steel and send through long threaded rods. You'd then need to be able to access inside the wall to add large washers and nuts. Your ledger board can then be fixed onto the wall, and additional washers and nuts can be used on the outside. That sandwiches and compresses the attachment. Brick veneer is not designed or allowed by building codes to support anything other than the weight of the bricks above.

Pedestal feet are designed for floating decks, and no attachment to the ground is required. Obviously, if you're in a region that sees cyclonic wind conditions, you would look towards a more secure foundation, but otherwise, the weight of the deck holds it in position. Once completed, the deck would weigh in the vicinity of a few hundred kilograms and shouldn't shift around.

You're creating a single-layer deck. Bearers are timbers that support the deck's weight and direct it to the footers, and that term is more commonly used on dual-layer decks as the joists are laid on top of the bearers. In your case, there are no real bearers, just timbers that bear weight. You have the joists that run across the deck and a framing timber that runs around it. It's acceptable to put supports on the outside frame, but the joists can also support the deck's weight. Whether the supports are on the exterior frame or placed slightly in from the edge on a joist makes no real difference. If you place the support on the frame you will be able to see it, and that's not particularly pleasing to the eye. Once again, check out the How To guide I linked to above, and you'll see how I've positioned the supports in from the edge.

Mitchell

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.