The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: Side Door

How to attach gate frame to brickwork?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to attach gate frame to brickwork?

Hello Members,

The Wood screws dislocated from the wall. Should the gap be filled again with cement, drilled and fixed. (or) any alternative fixtures are available to prevent this from happening again. Reckon due to the wind pressure the door is frequently getting pushed for above event to happen. Could you please list the materials for resolving this.

Intent to replace below lock mechanism with door lock that can be accessed from both sides of the gate. Can you please propose any suitable two way door lock and ways to close the holes in the gate (if that is exposed) after fixing the two way lock.

By the way, please propose suitable paint and tools (I'm paining for the first time) to touch up the scratches that were left over due to be movement of the dislocated gate.

Thank you.

MM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Side Door

Hello @Noyade

The weight of the gate is around 23Kg and the post is 50mm X 50mm; 1 mm thick.

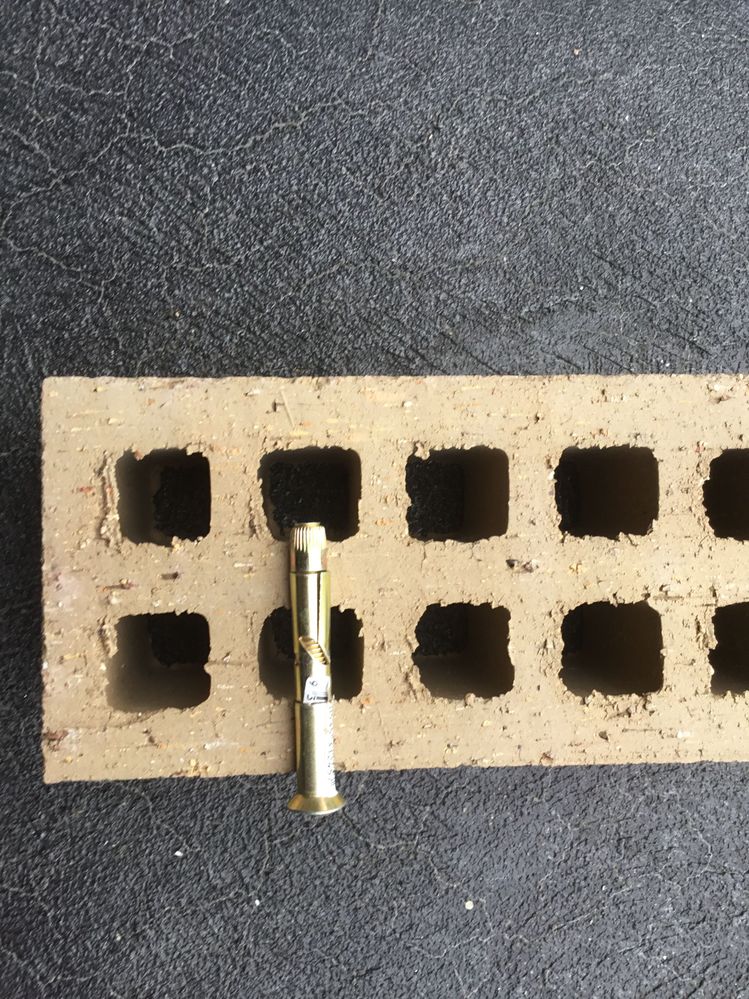

The plan is to secure above gate of 23Kg with 2 Dynabolts of 10 mm X 75mm.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Side Door

The post is 1mm thick.

Ideal position of Dynabolt is shown in below picture. One from top view and another from side view.

Should Dynabolt hold well to bricks ?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Side Door

Oops, I didn't look close enough.... I thought it was a wooden post when I said I didn't think that they were long enough.

You are correct for a steel post in which you are attaching it to the back wall of the post via a large hole.

I hope you will be using the Dynabolts with a nut and washer though.

The countersunk head will create a weakness in the hole in the steel, which you don't need to introduce, given that this post is taking the weight of the door. (Unless I am seeing that incorrectly.)

if you use a number of dynabolts (I'd be using at least 3, they aren't expensive) they will spread the load ok and not pull through the bricks.

A gate or a door presents a dynamic load - it shifts around as the door swings and has to withstand vibrations when the door is shut. If you don't clamp the post firmly to the wall those varying, twisting, loads will work the attachments loose in time.

I didn't fully understand the issue re transferring the holes, but if it is about getting the front and back hole to be the same, use a centre punch through the larger hole to get a mark in the steel for the drill to centre on.

If the issue is transferring the centre of the hole in the steel to the brick wall, drill a smaller hole in the steel than you need for the dynabolt - big enough to just accommodate the smallest masonry bit that you have, then with the post in place, drill a pilot hole into the brick. This will start your larger masonry bit in the correct place. Then drill out the steel to the correct size, (away from the wall) which will be the same size bit as the masonry bit needs to be.

You can then drill the hole into the brick before attaching the pole. (If' I've misunderstood the problem - ignore the above.)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Side Door

Hello @Noyade

I can buy the Dynabolt (locked with nuts); afraid nuts might drip down while fixing in to the square post.

Unfortunately, yesterday, while I was drilling one of the hole in to the post (brick side), I made a bigger hole on the post (brick side), where it should be 10mm of hole size; ended up in 15mm hole size. Not sure of the best way to handle this now. The option I can think of is to use washer of ID (Internal diameter: 10mm and OD: 15mm), just to patch up the enlarged hole and use another washer of (internal diameter: 10mm and OD: 25mm) for the Dynabolt to push the post to the brick wall. Sorry for the error.

Not sure, whether Bunnings has steel washers with above requirement. (Or) any Step Washer. A small mistake consumes more time now. Coming back to the point, with steel washers in place, will countersunk Dynabolt (or) Dynabold with nut suit better for the purpose.

On your message 'No need for the anchor to accommodate the post's width', I dont understand this.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Side Door

Hello @TedBear

Looking at your reply, it looks, I have to purchase Dynabolt with nut and not use countersunk Dynabolt and use 3 of them for the purpose.

For 'I didn't fully understand the issue re transferring the holes' in your message, if I use a centrepunch via the large hole, while marking, it might be offcentre. My question is to how to mark exactly at the centre. (All this is on within steel post, not on the bricks).

Your idea of transferring the hole to the brick (through steel post) is appreciated.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Side Door

Hi @nagumuthu , yes, the countersunk dynabolts are best suited to timber posts, where the countersunk head will give a flush finish to the post so it doesn't get in the way of a gate, etc. You can insert the dynabolt into the post with the nut already on, so it shouldn't drop down.

To get the centre of the other side hole, put the drill bit through the hole you already have and keep it straight while turning it a few times.

That will mark the centre. Then continue with the bit of the size you want.

If you would rather drill from the other side, use a small bit that is long enough to drill right through via the large hole, then turn the post over, using that small hole as the centre for the correct size bit.

Another alternative is to use a square and a pencil and transfer the centre of the large hole around the post by marking a line right around it.

That may not be as accurate if the post edges are not square and straight, but probably good enough for this task since the nut driver doesn't have to be perfectly straight to tighten the dynabolts.

You should be ok using a large, thick washer to fill in the gap for oversize hole that you accidentally drilled. The post will be kept at the right height by other means so the dynabolt just has to push it back against the wall, meaning the possibility of some sideways movement of the dynabolt within the oversize hole isn't going to be a problem.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Side Door

Thanks @TedBear. Your reply enlightens me on fixing but to the Dynabolt for preventing the drop. Good idea.

Thanks for the confidence in assuring the steel washer pushing post to the wall.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Side Door

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Side Door

Hello @Neo19

Thank you very much for sharing photos of your side gate. It looks very well anchored, and those four mounting points will keep it very secure.

Eric

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.