The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Living and Bedroom

- >

- Queen bed using Castle Joint joinery

Queen bed using Castle Joint joinery

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Queen bed using Castle Joint joinery

However the budget was limited, so I decided to build one using mostly construction lumber purchased from Bunnings (of course).

Material list

- 90mm x 35mm x 2.4m Untreated Pine x 4

- 90mm x 45mm x 2.4m Untreated Pine x 3

- 42mm x 19mm x 2.4m DAR Premium Pine x 4

- 75mm wood screws

- 65mm wood screws

- Feast and Watson Stain and Varnish

- Paint Brush

- Miscellaneous Items (Rags, Sandpaper 120, 180, 240)

Tools list

- Miter Saw

- Circular Saw

- Drill Driver, Impact Driver

- Hand Saw

- Chisel

- Miscellaneous tools (Mallet, Hammer, Tape measure)

Here are the build photos

I first cut all of the sides to slightly longer than the final lengths

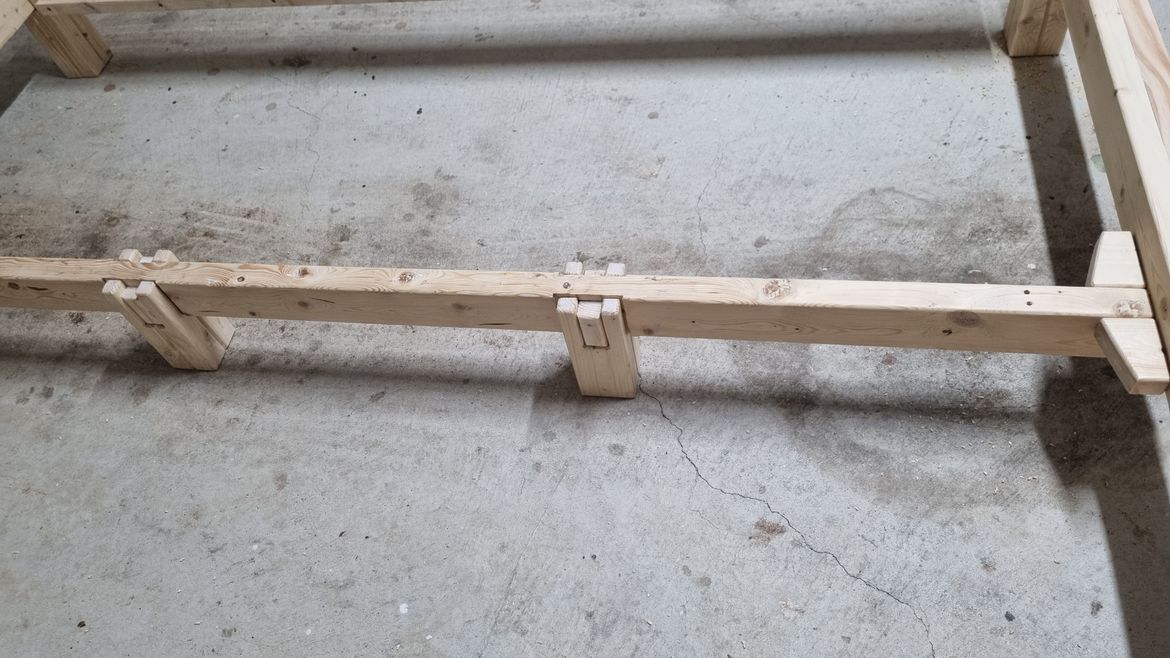

The legs were made by gluing together two pieces of 90x45mm pieces. I then cut the slots into the legs and the sides using a hand saw and circular saw to create the castle joints. Of course the cuts were not perfect and they had to be cleaned using a chisel and lots of filing and sanding.

The supports for the slats were created by ripping a 90x45 down the middle and gluing and screwing the piece to the inside bottom of the frame

To create a platform effect, I glued and screwed 42x19mm DAR pine to the outer side flush with the top. I had to plane the side of the 90x35mm that was on top to remove the rounded edges that are typical of construction lumber. This ensured that there wasn't a gap between the side and the platform edge.

Since I was using castle joints on the outer legs, I cut the legs on the middle support to also have castle joints. I also cut slots into the middle support to mate with the front and back sides of the bed frame and added supports on the inside to prevent the middle support from moving side-to-side

All of the vertical sides were cut to the final length at an angle and I ran a router with a round-over bit to smooth all edges. I also added a groove running along the middle of each side of the leg to hide the seam created by joining two 90x45 pieces.

I tested everything fits once, before it was time to sand

seal using a sanding sealer and sand again and finally apply three coats of Feast and Watson walnut stain and varnish.

This was the most difficult part of the whole process and getting the stain and varnish to be uniform and not drip was time consuming.

It was now time for final assembly

and enjoy the new bed

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Queen bed using Castle Joint joinery

Welcome to the Bunnings Workshop community @prashantpd. It's great to have you join us, and many thanks for sharing this wonderful project.

I love that you've spent the extra time on joinery. As someone whose patience typically finishes at butt joints, I appreciate the time you've spent constructing the frame. You've built a lovely piece of furniture, and I trust you are proud of the results.

The extra details you've provided on your project will really assist anyone wishing to replicate it.

Well done, and I look forward to your next project.

Mitchell

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.