The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- How To

- >

- How to replace a tap washer

How to replace a tap washer

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Beginner

Fix a leaking tap by replacing the tap washer. A tap washer is a rubber valve that creates a watertight seal when the tap is closed and prevents water from leaking.

Please note you may need to engage a licensed plumber for this project. If in doubt, consult your local building authority before you begin.

Steps

Step 1

Turn off the mains water tap.

Locate your water meter box and turn off the mains water tap. This is the main pipe supplying water to your house. You may need a pair of pliers to turn the tap off.

Turn on the tap that needs replacing and let the hot or cold water flow until all the water has drained.

Step 2

Remove the tap handle.

Identity the type of tap handle you have and remove it from the spindle. The spindle is the centre post that the tap handle uses to connect to the tap body. When the tap handle is turned it rotates the spindle and regulates the water flow.

The type of tap handle you have determines how you can remove it.

Lever or pin handle

Lever or pin tap handles typically have a hidden grub screw on the side that can be removed with an Allen key. If the grub screw is not visible, unscrew the tap’s pin handle and check to see if it is inside. Remove the grub screw to release the handle.

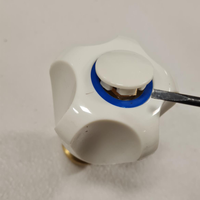

T-handle

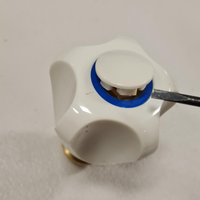

T-handle taps typically have a grub screw located on the side, a hidden nut underneath or a screwed hot/cold button on top. Remove the grub screw with an Allen key, the hidden nut with a vandal-proof spanner, or the button with an adjustable wrench to release the handle.

Standard plastic handle

Standard plastic handles usually have a brass locking nut within the handle that is hidden under a plastic cap. Use a flat head screwdriver to remove the cover cap and use pliers or a socket wrench to remove the locking nut.

Step 3

Remove the spindle cover.

Locate the spindle cover on your tap. This is a decorative or protective domed plate that covers the base or mounting area of the tap. It helps conceal any gaps or imperfections around the tap hole.

Turn the spindle cover anti-clockwise to remove it.

If it is stuck, spray the cover with WD-40 and allow to soak.

If the cover is fixed in place with silicone, use a craft knife to cut away the silicone.

Once you have loosened the cover, turn it and lift to remove.

Step 4

Remove the spindle.

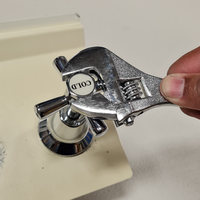

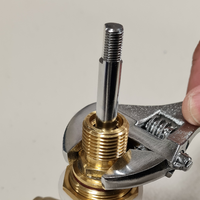

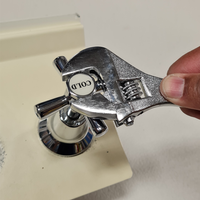

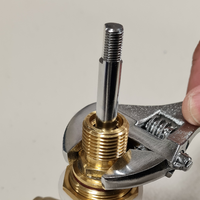

Position an adjustable wrench on the spindle body. Turn the spindle anti-clockwise to loosen it.

Once the spindle is loose, turn and remove it from the sink. The tap valve should now be clearly visible. This is a small rubber or fiber disc that forms a watertight seal within the tap body. It regulates water flow by opening or closing the water pathway.

If the tap valve is stuck or left inside the tap body, use multigrip pliers to pinch the tap valve’s post and lift out.

Step 5

Replace the tap washer.

Gather your tap valve repair kit.

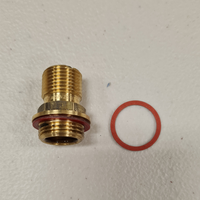

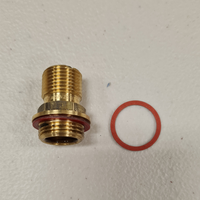

Hold the tap's brass body and turn the spindle clockwise to separate it from the body. Replace the old fibre washer on the tap's brass body with the new one.

Replace the O rings on the spindle. Apply lubricant to the new O rings and spindle. Re-insert the spindle back into the tap's brass body.

Now position the new tap valve at the bottom of the spindle and screw the tap body back into place. Use an adjustable wrench to tighten the nut.

Follow Step 1 in reverse order to re-assemble your tap handle.

Remember to turn the tap off before turning your mains water tap back on.

You have now successfully replaced your tap washer.

Materials

- Tap valve repair kit, like FIX-A-TAP Soft Turn Tap Valve Repair Kit - 4 Pack.

Tools

- Adjustable wrench

- Vandal proof spanner

- Allen key

- Multigrip pliers

- Craft knife

- Flat head screwdriver

- WD-40.

Images

You must be a registered Workshop community member to comment. Please join Workshop or sign in to join in the discussion.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.