The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- How To

- >

- How to build a saw horse

How to build a saw horse

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Beginner

Saw horses can offer reliable and stable support for work surfaces and D.I.Y. tasks like cutting and assembling materials, making them handy tools for woodworking and other projects.

Follow this simple guide to build a saw horse. You can customise its size to suit your needs. Repeat all the steps below to build a second saw horse and complete your set before use.

Steps

Step 1

Cut Pine pieces to size.

My saw horse measures 1000mm long, 750mm in height from ground to work surface and 550mm width from outside of its legs.

Use a tape measure and pencil to mark three points spaced 1000m apart on each of the five Pine pieces. You should have 15 lengths in total.

Now use a handsaw to cut these lengths. Don't forget to wear personal protective equipment (PPE) while cutting, including gloves and safety glasses.

Step 2

Mark the lengths for the rail pieces.

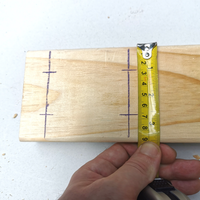

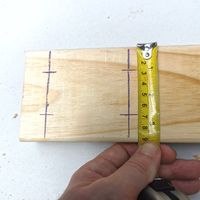

Take two 1000m cut lengths from the previous step. Use a tape measure and pencil to draw lines at the 100mm, 360mm, 660mm and 900mm mark from the end of the first length.

Now draw lines at the 110mm, 370mm, 670mm and 910mm mark from the end of the second length.

The marks on the second length differ from the first. This prevents the fixing screws from contacting each other in the following steps.

Step 3

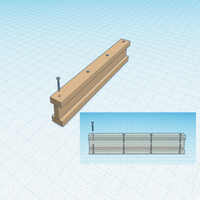

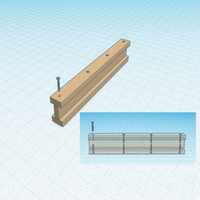

Join the rail pieces.

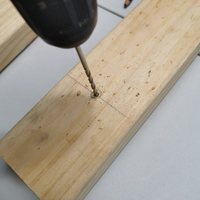

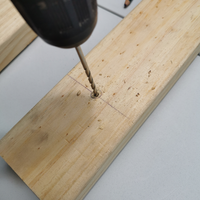

Drill through the centre of the marked lines created in Step 2 on your lengths with a 4mm drill bit. Countersink each of these holes.

Now take a new 1000m length and clamp it between the two marked and pre-drilled sections. With your 4mm drill bit, drill through the previously drilled holes into the new middle rail.

Use your drill driver and Hex5 impact driver bit to drive in the bugle timber screws and screw all three rails together.

Step 4

Pre-drill lengths for the leg sections.

Take four new 1000mm timber lengths. Place a line across all of the four ends at 25mm and 100mm.

Now intersect those lines 25mm in from each edge at 25mm and 65mm. These are your pre-drilling locations.

Pre-drill each leg at the four marked locations with your 4mm drill bit and then countersink those holes.

Step 5

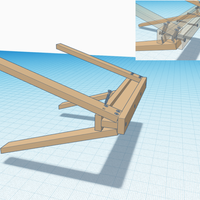

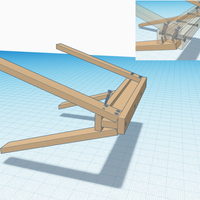

Attach the legs to the rail pieces.

Clamp the legs to the end of the top rails. Next, pre-drill through the existing holes in the legs into the rails.

Install your bugle timber screws to connect the legs to the rails.

Step 6

Trim the legs to your desired length.

The legs of the saw horse are currently 1000mm in height. You can reduce them to a more conventional height, like 750mm.

To reduce the height of your saw horse, place it upright on a flat surface. Now place a standing object, such as a 200mm high cardboard box next to each leg. Transfer the object's height across to the leg, marking it on all sides.

Cut the legs to length following the marked lines using a handsaw.

Repeat all the steps above to create another saw horse. Place your desired work surface or material in between the two.

You’ve now successfully built a functional and multi-purpose set of saw horses.

Materials

- Five lengths of 3600mm 90 x 35mm H3 treated Pine

- 14 x 85mm galvanised Bugle timber screws.

Tools

- Handsaw

- Drill driver

- Countersink bit

- 4mm drill bit

- Hex5 impact driver bit

- Clamps

- Tape measure

-

Pencil.

Images

You must be a registered Workshop community member to comment. Please join Workshop or sign in to join in the discussion.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.