- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Intermediate

Retaining walls not only help ensure soil doesn’t wash away down a slope. They can also become a landscape asset, providing terracing for sloping gardens and lawns or creating level pathways. They are also a great sustainable addition as they’ll slow down water runoff.

This step-by-step guide will help you to build a simple retaining wall using treated pine sleepers. It also includes a set of steps using a flexible design that can be used in many different environments.

Video Tutorial

Steps

Step 1

1/10Choose the right timber for the job. It’s critical that timber retaining walls be constructed from timber that is suitable for ground contact.

Timber has a number of classes and for most retaining jobs it’s the H or Hazard class that’s most important. For retaining you need to use timber with a minimum rating of H4. In treated pine this H-level is achieved through treating the timber. This is done under pressure with chemicals or other products such as micronized iron.

Commonly available CCA treated pine should not be used where you may have frequent contact with the timber, where any treatment may leach out, or in situations such as vegetable gardens. In these situations use ACQ or MicroPro treated timber.

Step 2

2/10Take some time to plan your retaining wall design, including a basic sketch. A simple, non-structural timber wall can easily be constructed by a anyone with just basic D.I.Y. skills and tools.

If you think you need a tall wall, consider whether you could use a series of smaller, tiered walls instead. You should seek professional advice if the wall height exceeds 400mm, if the wall is close to a boundary, or if it will be structural and carry a heavy or “live” load such as beside a driveway. Also check with your local council for any rules they have regarding retaining.

Step 3

3/10Determine the area where the wall will be. Hammer a peg around 1m out from both ends, run stringline between, and mark the line with paint. Mark points for posts. Every 2.4m or 3m sleeper must have posts at either end and one in the centre.

Step 4

4/10Excavate as needed to reach desired levels and dig post-holes. In our case we installed the smaller downhill wall first as it did not require posts, just digging in. This gave us a level to work from. If you encounter rock you may need to use a small rock-breaker. Note that a post-hole should allow for around 100mm space at the front and back of the post and 50mm each side to allow for both positioning adjustments and adequate concrete.

The depth of the post below the ground can be variable depending on soil type and topography. For example, a 400mm high wall in heavy soil on a minor slope could have as little as 200mm in ground. But if soil was loose or slope greater, then you may need the same height in-ground as above. If in doubt, seek professional advice.

Step 5

5/10Cut posts to desired length. We cut ours 800mm allowing for 400mm below ground. For extra support we used thicker 75mm sleepers for the posts. Use stringline, levels and tape measure to accurately set position and height. You can set posts a little high and trim off afterwards. Put around 30 to 40mm of gravel or concrete in the bottom of the hole, position post and add concrete following instructions on the bag. Check it is level on both the face and the sides. Repeat for all posts and allow to set.

Step 6

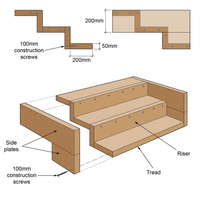

6/10Our wall included a small set of steps. These were assembled and dropped into place affixing them to the first post and existing wall. See diagram for details of the design. The size can be adjusted to suit.

Step 7

7/10Drop 75mm sleepers in behind posts. For a continuous, longer wall the sleeper end should be in the centre of the post. Check level is correct and use 100mm construction screws to secure. There should be a screw added at top and bottom of sleeper face at each post. At wall ends sleeper end should be flush with post and additional screws may be added for extra strength.

Step 8

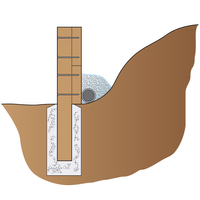

8/10Position drainage pipe behind wall and run output end to suitable location where it can be accessed. Cover pipe with gravel and then cover this with filter fabric. (see diagram for cross section of wall and drainage)

Step 9

9/10If used, connect un-slotted pipe to drain pipe output and run to the required point. Drainage water must never be drained to a boundary so direct it to a suitable stormwater drain on-site or into a garden area.

Step 10

10/10The cut material can now be used to fill behind the wall. Pat it down to remove large air pockets but do not overly compress it. You can now add turf or plant out the area to finish it off.

Materials

Tools

To create a treated pine wall 2.4m long by 400mm high, we used the following materials:

- Treated pine sleepers – Two sleepers for the rails measuring 200mm x 50mm x 2400mm, plus one for the posts measuring 200mm x 75mm x 2.4m

- 100mm timber construction screws (small pack)

- Pre-mixed Quickset concrete with a strength rating of at least 24MPa (minimum of 3 bags)

- 65mm slotted agricultural drainage pipe

- 65mm un-slotted agricultural drainage pipe (optional)

- 20kg bag of blue metal drainage aggregate (minimum of 2)

- Filter or drainage fabric

- Set-out paint

- Set-out pegs

- Safety gear – eyes, ears, breathing, hands and feet

- Digging spade or shovel and mattock

- Wheelbarrow

- Levels (long and short)

- Tape measure

- String line

- Builder’s square

- Power saw

- Drill-driver

Images

You must be a registered Workshop community member to comment. Please join Workshop or sign in to join in the discussion.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

| Subject | Author | Posted | |

|---|---|---|---|

| June 2023 | |||

| November 2022 | |||

| September | |||

| October 2021 | |||

| February |