The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- How To

- >

- How to build a pool pump cover

How to build a pool pump cover

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Intermediate

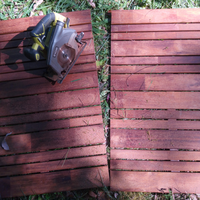

A timber pool-pump cover can enhance your garden by concealing your pump and filter behind beautiful-looking natural wood.

This step-by-step guide will show you how to use ready-made Merbau fence panels to build a sturdy cover that opens wide for easy access to your pump and filter. You can use our measurements or adjust them to suit your own set-up.

As this project involves power tools, please follow all safety guidelines provided by manufacturers and use the recommended protective gear.

Let us know if you have any questions. We’d be happy to help.

Steps

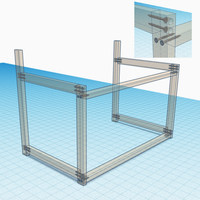

Step 1

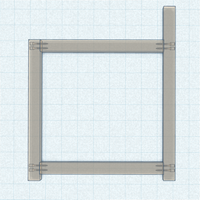

Cut frame sections.

The footprint of your pool-pump setup will determine the size of your pump box. Ensure that the frame clears all components and allows access to equipment. You can adjust the frame size to create a larger or smaller box.

Begin constructing your box frame by cutting up your 70 x 35mm treated Pine. You'll need:

- Two lengths of 1070mm (for the rear uprights)

- Two lengths of 870mm (for the front uprights)

- Four lengths of 760mm (to join the uprights)

- Three lengths of 1430mm (horizontal sections to join the side frames together).

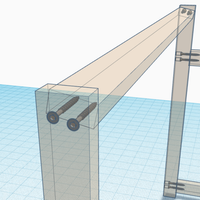

Step 2

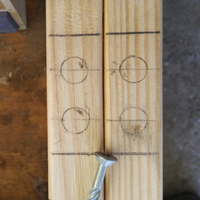

Assemble side frames.

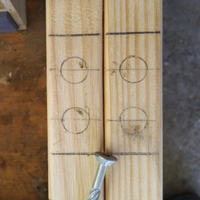

Take one of your two 870mm front leg sections and make a mark 70mm from one end. Drill two 4mm holes the depth of the timber in the centre of the area between the mark and the end. At the other end of the leg section, measure 50mm from the end and place a mark. Measure 70mm from that mark and make another mark. Drill two more 4mm holes in the centre of the area between those two marks.

Repeat for your second front leg section.

Now switch to your 12mm drill bit. You’ll use this to provide countersinking for your batten screws.

Wrap a piece of masking tape around the drill bit 20mm from the tip. This tape will act as a depth gauge. On one side of your front leg sections, drill out the 4mm holes to a depth of 20mm.

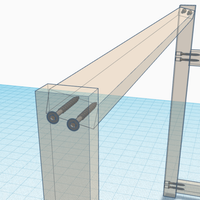

Use your batten screws to connect your front leg sections to the 760mm sections.

Now take the 1070mm sections for your rear legs. Pre-drill as with the front legs, and attach to the 760mm sections. You should now have two completed side frames.

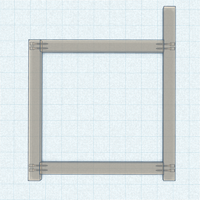

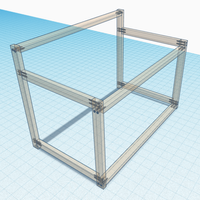

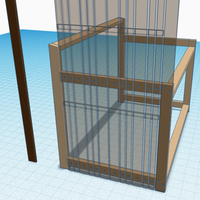

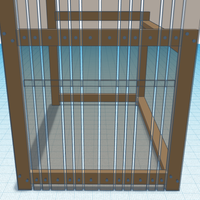

Step 3

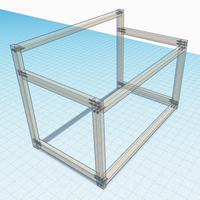

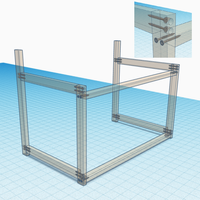

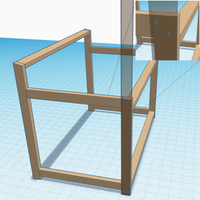

Connect side frames.

Directly below where your 760mm sections join the front leg sections, pre-drill the side of the frames at the top and bottom. Connect two of your 1430mm joining sections, one at the top and the other at the bottom, with two batten screws.

The rear 1430mm horizontal joining piece must be angled to approximately 15 degrees from flat. Pre-drill and attach as per other sections. Then cut the tops of the rear legs at the same angle.

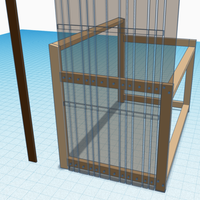

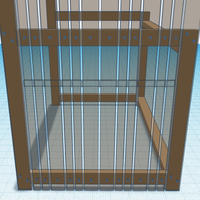

You'll now have a completed frame as per the images.

Step 4

Stain the frame.

Take the Merbau stain and apply it to the frame with your brush. One solid coat should be enough, but you can do a second coat if required.

Allow to dry before proceeding to the next step.

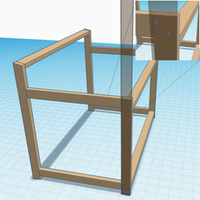

Step 5

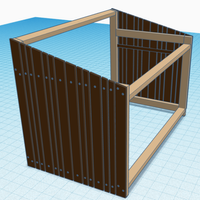

Attach panel to side frame.

Take two Merbau panels and cut off the first and last boards. Unscrew the remnants of the cross bracing by undoing the screws and lightly tapping them with a hammer to dislodge them.

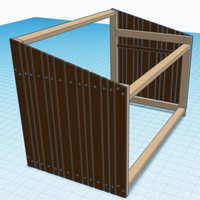

Attach one of the first boards over the outside face of one of the front legs with 25mm screws. Next, place the rest of the panel in line with this first board and screw it into position on the side frame. Once it is in position, attach the last board to the rear leg.

Repeat for your other side frame.

Once the side panels are in place, set a guide from the top of the front legs to the top of the rear legs. Cut the panels at that angle with your circular saw.

Step 6

Cut lid panel and attach bracing.

Take one of your remaining Merbau panels and cut it in half at 900mm to create your two lids.

Cut two 900mm lengths of your 69 x 15mm Merbau screening to make braces for the cut sections of the lid panel.

Set these at the cut ends of your Merbau panel. Pre-drill one hole per panel slat with your 3mm countersink drill bit. Attach the brace to the panel with your 25mm screws.

Step 7

Create hinge mounting plates and attach lids.

Measure the distance between the edge of the screening installed in the previous step and the first bracing piece. This distance should be 200mm. Cut four 200mm sections of your Merbau screen. Position these pieces and pre-drill with your countersink bit as per the images. Attach with 25mm screws.

Position your hinges over these mounting plates and install them with 25mm screws.

Step 8

Create and mount lid support.

Measure the gap from where your lid meets the side panel to the top of the front horizontal joiner. This gap should be about 65mm.

Cut a section of your 70 x 35mm Pine to fit.

In the centre of your horizontal joiner, where the two lids meet, pre-drill two 4mm holes. Screw the lid support into position with two of your batten screws.

This support stops the two lids drooping in the middle and also provides a mounting location for our magnetic door catches installed in a later step.

Step 9

Attach gas struts.

Attach one of your gas strut mounting brackets to the hinge plate and the other midway along your side frame with 25mm screws. Connect the gas strut and repeat for the other side.

Step 10

Cut door panel and mount.

Take your remaining Merbau panel and cut it in half at 900mm to create your two doors. Remove a portion of each door to suit the width of your frame. The two doors' combined widths should be the same as the front of your structure.

Attach two hinges per door at 200mm from the top and bottom of the door with your 16mm timber screws. Connect the hinges to your frame with 50mm timber screws.

Step 11

Attach magnetic door latches.

Attach your magnetic latches to the sides of the lid support. Attach your latch plates to the top corners of your doors.

Step 12

Attach door handles.

Pre-drill 4mm holes in your doors to suit your door handles. Attach door handles to doors.

You now have a complete Merbau pool-pump and filter cover.

Materials

-

Four Merbau fence panels measuring 1800 x 902mm

-

Two 2700mm lengths of 69 x 15mm Merbau screening

-

Five 3000mm lengths of 70 x 35mm H3 treated Pine

-

1L deck and exterior Merbau stain (can be oil-based or water-based)

-

Masking tape

-

Two 192mm matte black hollow rectangle handles

-

Eight 300mm zinc-plated tee hinges

-

Two 325mm gas struts

-

8G x 16mm timber screws, 100 pack

-

8G x 25mm timber screws, 100 pack

-

8G x 50mm timber screws, 50 pack

-

100mm batten screws, 25 pack

-

Two 46mm magnetic catches.

Tools

-

Drill driver

-

Circular saw

-

Set square

-

Paintbrush

-

12mm drill bit

-

4mm drill bit

-

3mm countersink drill bit

-

Hammer

-

Clamps.

Images

You must be a registered Workshop community member to comment. Please join Workshop or sign in to join in the discussion.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.