The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garden

- >

- Jaw teeth suggestions wanted for vice fo...

Jaw teeth suggestions wanted for vice for chainsawing

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Jaw teeth suggestions wanted for vice for chainsawing

I always felt the 50 mm height on the vice ends on those foot operated vices too small. I'm in the process of making a poor man's version of the Triton (Rockwell) 100 mm in height using 50 mm angle iron 5 mm thick. What I want to do is be able to screw/bolt plates with 'teeth' that will grab a tree limb for chainsawing.

The plates will be 100 mm high X 170 mm long and 5 mm thick

Not sure how to go about it and looking for suggestions/ideas please.

Cheers!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Jaw teeth suggestions wanted for vice for chainsawing

This shows the difference in 'grabbing ability' with the original 50mm on the left and the new 100mm on the right.

Now I just need 'teeth.' 🤔

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Jaw teeth suggestions wanted for vice for chainsawing

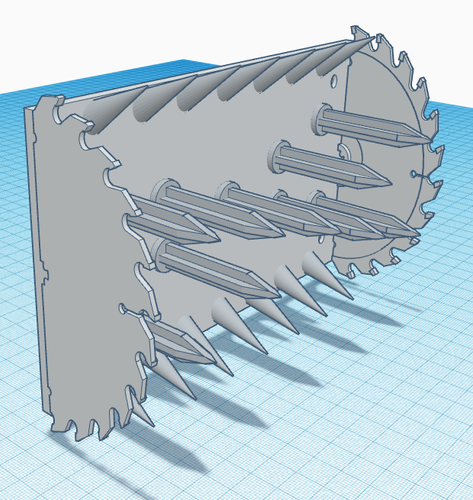

Are you sure you're looking to build a vice for cutting tree limbs and not some sort of medieval torture device @Noyade? 😉

I'd start off simple with some basic toothed jaws. They'll likely to do a good job at holding a variety of different sized logs. Also, having consistently sized teeth will ensure that you don't get over-penetration of a single tooth and then have difficulty getting it back out of the log.

It would be best to weld up a solid jaw, but you might actually get away with two sections of steel angle with the teeth cut into them. I've added a rendering below. I couldn't help but contribute the second one. You know, just in case.

Keen to see how your experiments go. I think you should make a few different types and give us your review of them.

MItchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Jaw teeth suggestions wanted for vice for chainsawing

Wow! Thanks for the drawings - much appreciated! 😀

I very much like the top idea and I'll probably go with that with angle iron and connecting plate. Simple idea. Mine were becoming too elaborate.

I'll leave the bottom idea for the torture chamber.

Weather is turning miserable so I've quit for the day.

But so far I'm pleased with the extra clamping capacity.

Cheers!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Jaw teeth suggestions wanted for vice for chainsawing

Not a lotta progress today - weather was miserable.

I just cut the four pieces of heavy angle iron which will become the teeth - with my elderly Fastacut powered hacksaw....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Jaw teeth suggestions wanted for vice for chainsawing

Hi @Noyade

Thanks for the update on your project. I agree the weather was not ideal today, but between cutting the steel manually and using your reliable Fastacut I'm putting my vote for the Fastacut.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Jaw teeth suggestions wanted for vice for chainsawing

The Fastacut is now a piece of history I think. I remember my carpenter/builder father setting me up in a chair as a young boy with this machine and my job was to cut dozens of steel pieces for his work. I have a 14" abrasive drop saw but this machine is cathartic to watch/use and produces somewhat more accurate cuts, with less sparks and noise.

Problem these days is sourcing the blades.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Jaw teeth suggestions wanted for vice for chainsawing

Rapid progress. Better weather today.

Many thanks again Mitchell - your idea was much better than what I was originally gonna go with...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Jaw teeth suggestions wanted for vice for chainsawing

I'm not sure now if the jawed teeth should come together of if there should be an over-bite?

Dentists would say no.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Jaw teeth suggestions wanted for vice for chainsawing

Hi @Noyade

Those teeth look perfect to hold large ungainly timber posts and branches. I'm sure a lot of our members will be looking forward to the final reveal once you've attached the metal jaws.

Please keep us updated with your progress, we look forward to seeing the vice in its final form.

Eric

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.