The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garden

- >

- Re: DIY spiral winder machine for gabion...

DIY spiral winder machine for gabion baskets

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

DIY spiral winder machine for gabion baskets

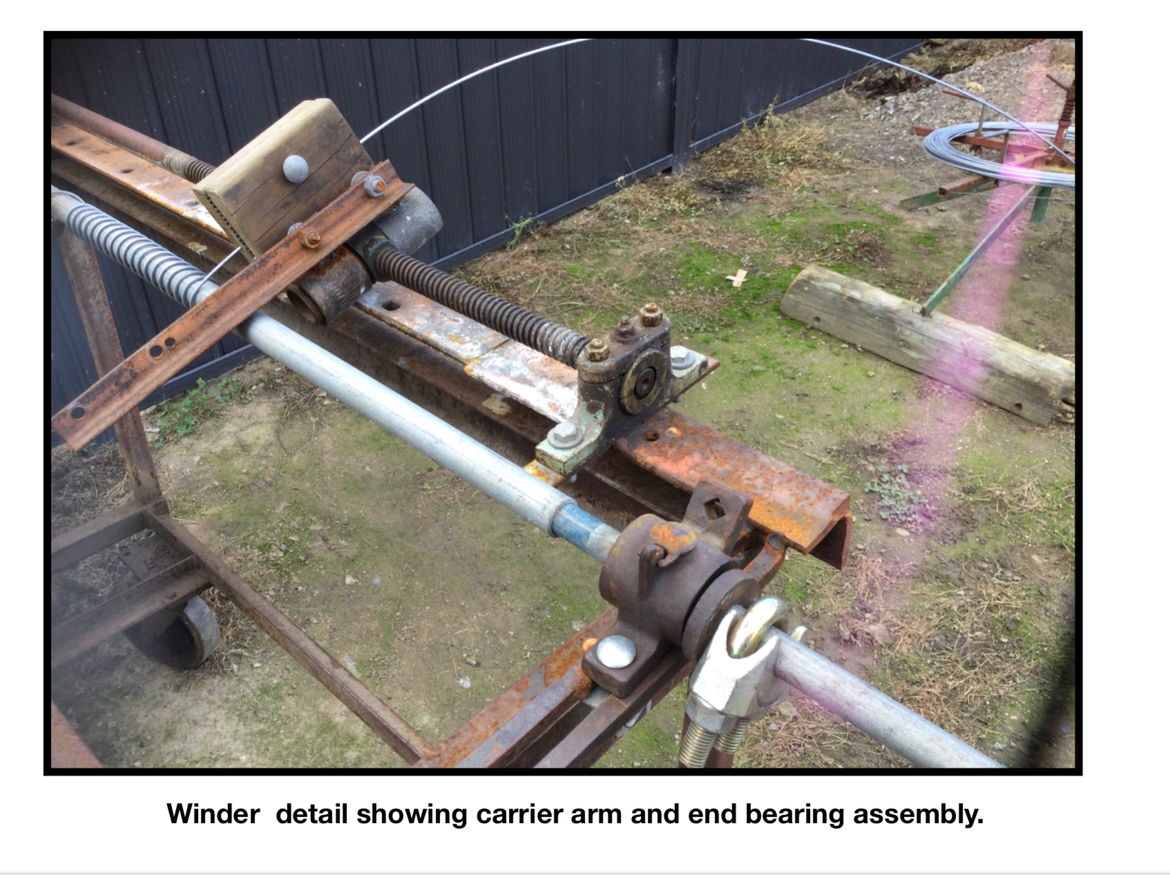

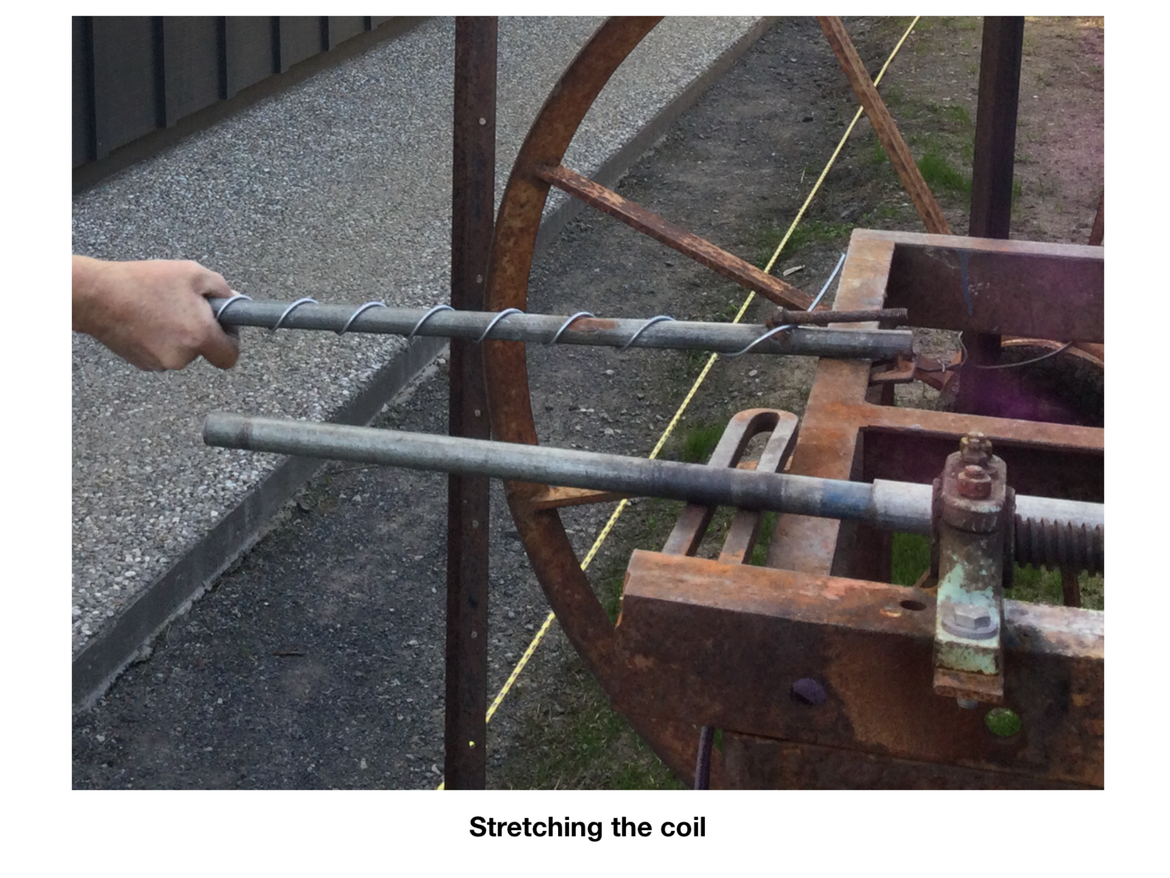

I wanted to build my own gabion fence (35 metres wide x 975mm high x 525mm deep) starting from scratch. I wanted it to be an artisan project, so I built my own spiral winder from parts of machinery I had lying around the farm. The cogs came from a Massey Harris seed drill, and I used a length of acme thread as I wanted the spirals to be even, consistent and regular to make them easier to wind onto the mesh. I used hog rings to hold the mesh together prior to winding the spirals.

If building your own, it is important to remember that the lead shaft needs to turn a bit faster than the winding shaft so that the carrier arm moves at least the thickness diameter of the wire per revolution. I used 3.15mm fencing wire. Looking at the figures there was a 2:1 ratio involved, and I would use 3/4" acme 6 TPI thread if purchasing a length. If using round bar for the winding shaft and stretching pole I would use 25mm and 20mm respectively as this would still give a 5mm differential to allow the coil to stretch.

I was fortunate enough that everything I had, worked and gave me approximately 1 to 1.5 turns per 75mm mesh square. There were no mathematical calculations involved apart from the number of turns required!

Materials

- Large cog X755, 40 tooth, 175mm diameter

- Small cog X597, 19 tooth, 90mm diameter

- Cog housing for large cog X680

- Acme thread, 1" diameter 5 TPI (threads per inch)

- Pipe for winding shaft 27mm OD

- Pipe for stretching pole 22mm OD

- Bearings to suit acme threaded rod and winding shafts.

- Steel to mount machine parts onto.

- Bolts

Tools

- welder

- spanners

- wire cutters

Steps

Step 1

Step 2

Step 3

Step 4

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: DIY spiral winder machine for gabion baskets

Hello Dave, thanks for your compliment. However I did come across your posting about the “Large gabion retaining wall” and it was your picture of the wire wrapped around the broom handle that prompted me to join up and do a posting about my spiral winder made out of “bits and pieces”, as I thought it may help someone. The spirals wind on relatively easy and I have made them up to 1000mm long and a few at 1200mm although they were a little bit harder to twist on towards the end.

If you would like to make your own machine please don’t hesitate to correspond further, as I could make some suggestions.

Regards.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: DIY spiral winder machine for gabion baskets

Hello Akanksha, many thanks for your nomination in the D.I.Y. July 2023 competition.

I have read through the Terms and Conditions of this competition and I am ineligible to enter as I am a New Zealand resident.

Thanks anyway for considering me as an entrant in this competition.

Regards.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: DIY spiral winder machine for gabion baskets

Thanks for clarifying, @Xfarma21. It's amazing to have you contribute your project to the community, and I very much look forward to seeing what you tackle next.

Please keep us updated on all the projects and plans you have going on around the home and garden.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: DIY spiral winder machine for gabion baskets

Morning @Xfarma21

![]() Thank you for the compliment also! Yeah I would have loved this at the start of the gabion walls. But now I have only a fairly large one and some small ones that need to be done (tho knowing me I will find other walls to build) Will keep you in mind tho as even the ones I have left will use a resonabale amount of spirals. That broom handle is a lot slower lol I also found that the longer the spiral the tighter it would become on the handle. The problem would be where to store it between uses. And by me thinking that it shows I am half considering to make one

Thank you for the compliment also! Yeah I would have loved this at the start of the gabion walls. But now I have only a fairly large one and some small ones that need to be done (tho knowing me I will find other walls to build) Will keep you in mind tho as even the ones I have left will use a resonabale amount of spirals. That broom handle is a lot slower lol I also found that the longer the spiral the tighter it would become on the handle. The problem would be where to store it between uses. And by me thinking that it shows I am half considering to make one ![]()

Thanks again

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: DIY spiral winder machine for gabion baskets

Thanks Dave, the machine is only mounted on my work bench and is removable. You could make one up that is mounted on 4 removable legs which would make it easier to transport and store.

- « Previous

-

- 1

- 2

- Next »

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.