The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: Folding and rolling mitre saw statio...

Folding and rolling mitre saw station

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

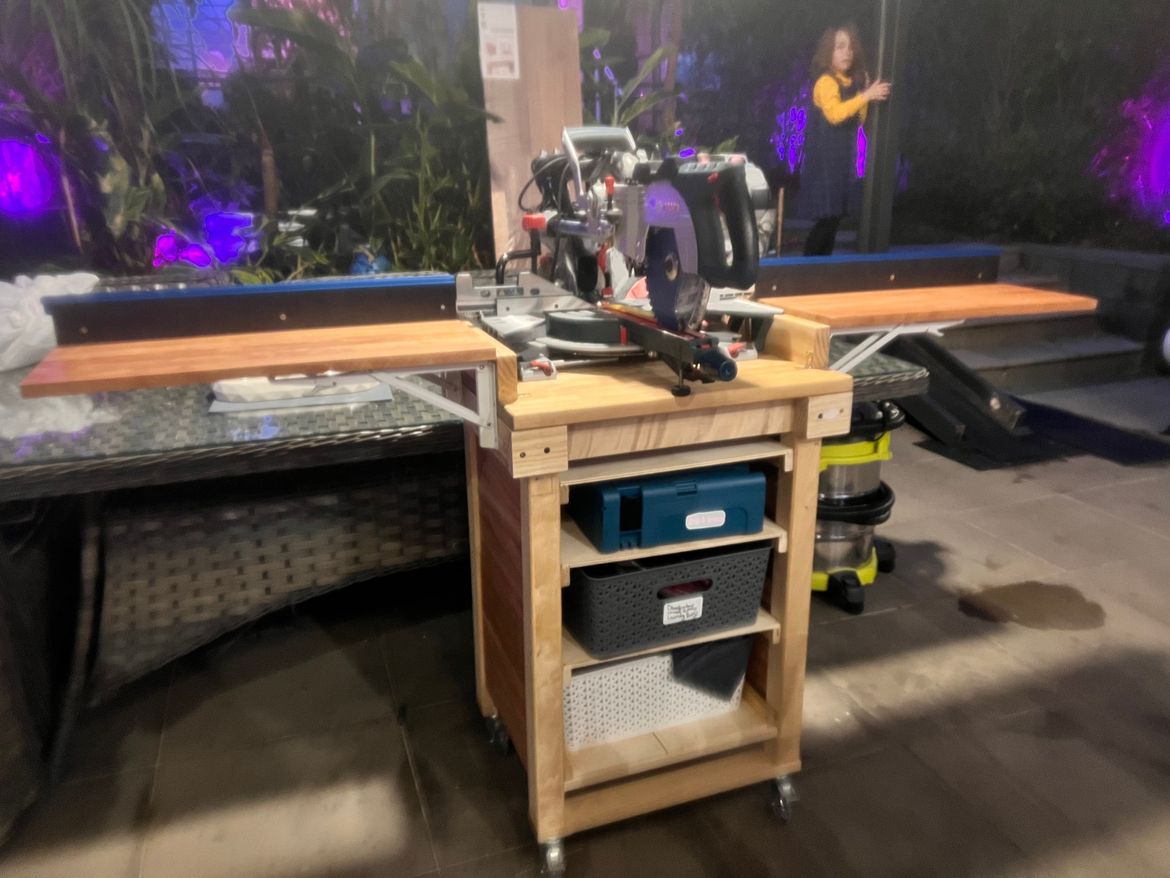

Folding and rolling mitre saw station

I have a tiny shed - 2metres by 900mm. It’s basically to store my tools and I bring them out into the backyard to make things. I wanted a way to create Rolling tool chests that also housed my big tools like my mitre saw and Table saw. I wanted them to be kinda like transformers- become a fully operational workshop when I need, but quickly fold down and easy to put away, because I am a mum and have limited time to build things, and I don’t like having tools out when little fingers are around.

So this is the mitre saw station. I Hacked an ikea butchers block I had and built folding wings with a fence that will allow me to add stop blocks. Overall cutting surface is 1.8 metres which is awesome. Currently I have shelves but will put 4 drawers in to hold tools.

I love the fact that I can roll out, plug in and fold out my station in less than 5 minutes.

Materials

- Old ikea rolling butcher block

- 4 75mm castors

- 70x30mm pine around the edges to make the sides flush with the top and next to the saw to allow me to add fold up hinges

- 4 folding locking hinges

- 2 Okumu 305x1200 panels to fill in the back and sides of butchers block

- 2 42x19 pine battens split in two to make runners for shelves but eventually drawers

- 1 Okumu 305x1200 panels split in half to create the wings

- 2 42x19 pine battens Laminated together to make the back fence support

- 2 600 mm x 60 mm strips of form ply to make the front of the fence

- Kreg Trak and stop kit to sit on top of the fence and allow me to slide on stops and it also has a measuring tape on each side

Tools

- Mitre saw

- table saw or circular saw

- Drill

- Driver

- Kreg Pocket Hole Jig

- Measuring tape and square

- safety gear

Steps

Step 1

1. Strip out shelves in old butchers block

Step 2

2. Cut Okumu panels to size to fit back and sides of butchers block

Step 3

3. Cut 1 okumu panel in half for the wings

Step 4

4. Cut 70x30 pine to size to wrap around the back and sides of cart frame

Step 5

5. Cut two pieces of 70x30 pine to the same width as the okumu wings

Step 6

6. Laminate 2 pieces of 42x19x1.2 pine together and clamp

Step 7

7. Cut two pieces of form ply or whatever you have on hand to 600x 60 mm for the fence

Step 8

8. Trim two of the cart legs to the same length as the other two that already have wheels on them.

Step 9

9. Sand and seal all timber including butchers block top. I used Osmo.

Step 10

10. Drill pocket holes in Okumu panels for the side and back.

11. Attach okumu panels to side and back between the legs, making sure they are flush with top rail.

12.Attach 70x30 pieces to the side and back so side is now flush with top.

13. Split some 42x19 by 1.2m (3 approx) in half so now 21x19 and then cut them to length to act as runners for your shelves or drawers.

14. Attach runners at your desired intervals to create shelves.

15. Cut some 7mm ply to size to act as shelves and attach to runners.

16. Attach butcher block top back to the top.

17. Add 4 castors to the legs

18. Centre mitre saw on the butchers block

19. figure out where to place your wings so your wing fence lines up perfectly with your mitre saw fence and your wings are level with the plate of mitre saw.

20. attach the last two pieces of 70x30 pine to the top of the butchers block in the position you have marked above

21. attach the 4 folding hinges

22. cut your laminated 42x19 pine in half

23. attach pine to back of wing

23. attach form ply fence to wing and pine backer - make sure to countersink screws

24. take two pieces of the Kreg track stop and drill holes and screw into fence.

25. Clamp wings to fold up hinges and ensure that everything is flush and square

26. attach wings to hinges.

27. Add measuring tape to Kreg track stop on either side and attach stops.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and Rolling Mitre Saw Station

Hi @RainbowDiY

Thank you so much for sharing your fantastic transforming and rolling Mitre saw station. It's certainly more than meets the eye! What a clever use of the butcher block and adding fold away wings. It's just so convenient with having a large platform to cut wood and yet it takes up minimal space when folded away. I'll have to add this to my bookmark collection.

Again, thank you for sharing such a clever project.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and Rolling Mitre Saw Station

Brilliant design! @RainbowDiY And lovely saw (Bosch?).

Is the saw fastened down or moved to adjust to your 'swinging' fences/supports?

"I bring them out into the backyard to make things."

Same here. Radial-arm saw, table saw, band-saw, planer and drill press - all on wheels.

Now for the sliding saw. 🤔

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

Good Morning @RainbowDiY

Now another one to add to the list! Brilliant idea you have come up with. I lug my drop saw out from under the house of the back room, catching it on every door frame or step... I really should have something on wheels ![]() Think I will have to have a go at making something along these lines.

Think I will have to have a go at making something along these lines.

I do like how your castor wheels have locks on them! ![]() And also that your bench height means you dont have to bend!

And also that your bench height means you dont have to bend!

Now need to come up with a list board for all the projects I want/need to do!

I just had a look at what "Kreg Trak and stop kit" is, and now it makes perfect sense ![]() Very handy.

Very handy.

I project that really works and saves time ![]()

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

I particularly like the extended fence - an accurate fence is crucial at times and although all saws have them - sometimes they're not big enough.

My current set up below.

The saw is bolted down to a plywood layer held by the Ozito clamps. Call it 'fixed.'

Any thoughts on how to make something to produce fence extensions in this situation?

(Remember when some Ozito products were yellow? 😁)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

When you say "fence" you mean the horizonal bars?

I dont have one 😕 lol I use some timber stools/horses to rest the saw on and then use more stools either side and pieces of timber to jack the height up.

I like @RainbowDiY 's fence? and even yours could be modified. Flat board with three pieces of timber screwed underneath them (so 70mm, then space of 30mm, 70mm, space of 30mm and then another 70mm piece) so it can then sit flat side up with timber, steel runner, timber, steel runner, timber to keep it locked in place. Can draw the profile pic if you want ![]()

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

Maybe my terminology is wrong @Dave-1

I've always called the upright alloy metal, which is ninety degrees to the saw surface, as the fence. When @RainbowDiY swings those wings up - the fence will be increased dramatically in length with more accurate cutting.

I want to see if I can extend as well - but with the current system I have.

And it may not be possible. It's just a thought.

Apologies - I should have started another thread. If the moderators can move this for me - it would be appreciated.

Cheers.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

Think I was the one with the misunderstanding "Fence" makes sense. And still think the thread works ![]()

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

Absolutely brilliant @RainbowDiY.c Thanks for sharing how-to the details.

I have all my power tools aligned with my bench tops, but my drop-saw isn't as portable as I wish it was, so I am now inspired to modify it using your design.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and Rolling Mitre Saw Station

Thank you Eric. I am just finishing up my Table saw rolling tool cart so watch out for that one!

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.