- Bunnings Workshop

- >

- Featured Projects

- >

- D.I.Y. paling fence

D.I.Y. paling fence

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Pine palings used to replace a wooden fence wrecked by termites.

The project

Part of our backyard paling fence was rotting and warped due to termite damage years ago that we had treated but didn’t have the time to replace.

The section of fence is behind our shed and lately we have had a few unwelcome visitors jumping the fence and running through our backyard. So, we decided to make the fence taller to put them off. We did it in a day, starting early in the morning before the heat set in.

Finally, we made time to fix it and our neighbour kindly helped us, as we had helped them with their paling fence. It was only one section that was the worst. Eventually we will replace the rest of the fence, which is a little warped, but fine.

We laid out all of the materials the day before.

We also had the tools laid out in the shed ready to go, along with a good extension cord to run from the shed to the back fence. That was for the drop saw to cut all the timber and a trestle table setup as well.

Have a couple of mini trestle tables on hand when you are doing a D.I.Y. project - it makes it so much easier to keep everything organised.

Steps

Step 1

We pulled down the old paling fence, being extremely careful with the nails sticking out.

We wore gloves, but be super careful with the old timber. We took it to our local recycling waste centre.

Step 2

I'm not sure if you can see at the base but we had to remove heaps of sand the local council had put there when they put a new footpath in. The sand covered the base of the fence and because it was wet all the time, the termites moved in and caused havoc. We had to get that sorted out.

We put in new timber attached to the posts for the boards. The cross beams were bolted in.

Step 3

The planks were spaced out just enough so they could be overlapping each other.

I’m sorry but I didn’t get a spacing size.

The guys just used an off-cut plank that was trimmed down to use as a spacer.

Step 4

Once the first layer of planks were attached, the second layer of planks was added.

We were very lucky our neighbour had a nail gun. It just made it so much easier to work with.

Step 5

We just replaced the old Colorbond capping and tek screwed it on.

Now look closely at the gap at the bottom of the fence. We sorted that out, too, so it isn’t a safety hazard.

Step 6

I only applied the used motor oil to the base of the fence to protect it. I had no idea it is an old remedy.

Step 7

We placed concrete film into the gap.

Back filled with blue metal.

Then we cut off the excess film sticking out.

Step 8

Replaced the capping.

The capping is faded and bent out of shape in some spots but it was still OK to reuse it.

Step 9

This shows you how much better it looks now against the existing fence. We will get to that old part soon.

We are so grateful to our neighbour for helping us. We always help each other out. So between the three of us, it took approximately five hours to complete. It was a messy project but it's well worth doing. I hope this project will help you if you have the same fence as us.

Tools and materials

Materials used in the project:

- 55 x treated Pine paling fence CCA 150 x 17mm 2.4m

- 9 x structural treated Pine 90 x 45mm 2.4m

- Galvanised 10M x 60mm bolts and nuts

- Washers for the bolts and nuts

- Tek screws

- 11 x 20kg bags of blue metal

- Concrete liner

- Old engine oil.

Tools used in the project:

More inspiration for your fencing project

Workshop member Hazel took just 90 minutes to finish her front fence build.

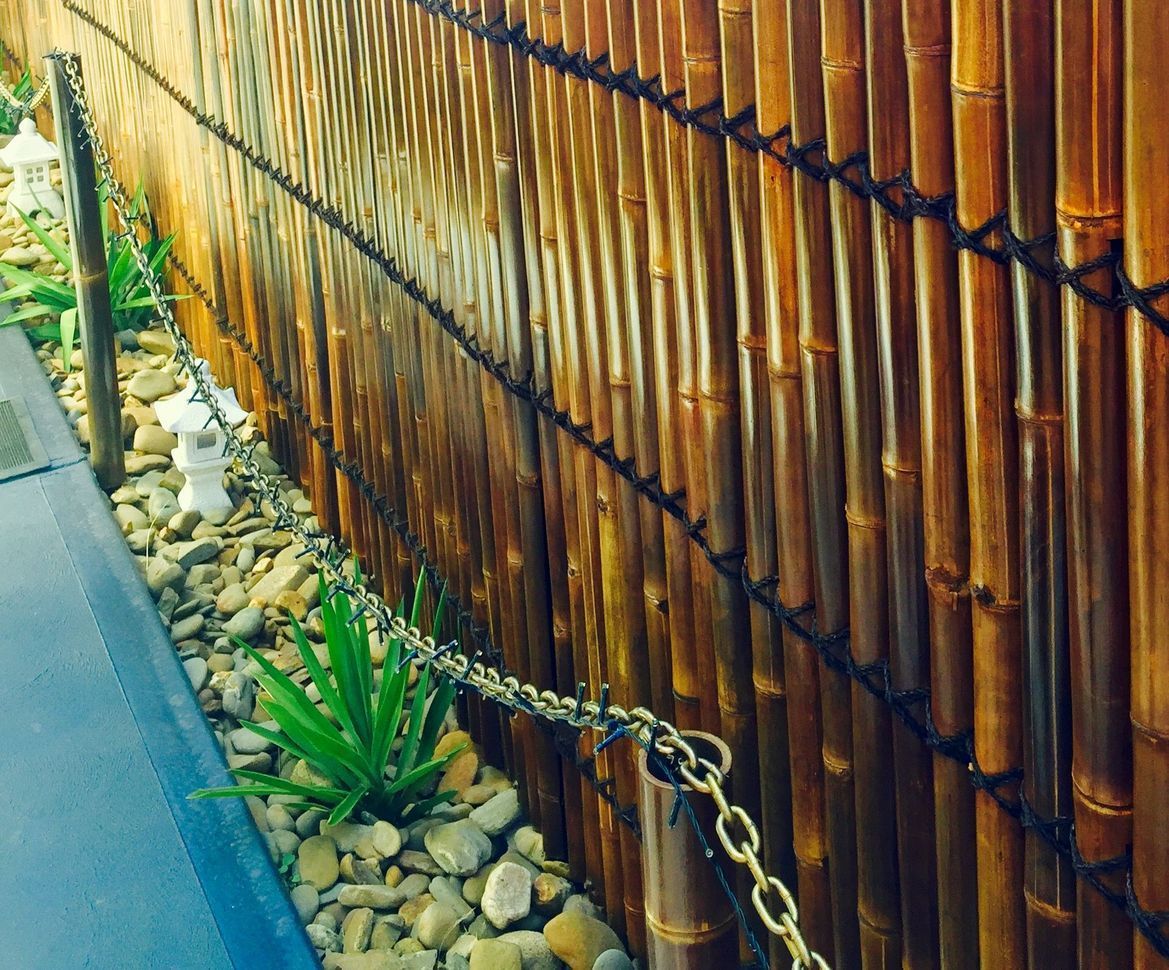

Community member Shannon added a touch of Bali to his backyard with this Bamboo fence panel for extra privacy.

For more great ideas check out our Top 10 most popular fence projects by Bunnings Workshop community members.

- Tags:

- Outdoor

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

G'day Mitch @mich1972

Looks like you had a good day - and a productive day! Well done! 👍

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Good Afternoon @mich1972

![]() I should have known it was your work! Thats a nice fence! And seriously love the way you have descibed and actually put the new one in.

I should have known it was your work! Thats a nice fence! And seriously love the way you have descibed and actually put the new one in.

I was most impressed with the gravel base and the protectrive sleeve to keep it seperated from the timber and allow drainage/support of the path at the same time. It really looks liek a professional fencing job ![]()

Dave

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Great work ![]()

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Thank you everyone for your kind comments !!!!!!

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects