The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Featured Projects

- >

- D.I.Y. air conditioner cover

D.I.Y. air conditioner cover

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

An air conditioning unit cover made with a timber frame and slats.

The project

Inspired by the many air conditioner covers by Workshop members such as the custom air conditioner cover by @DoSimpleBetter, my partner and I decided to give it a crack and make our own.

We recently had our apartment's HVAC system upgraded from a single-head Rinnai split system to a multi-head MHI system purchased from Bunnings.

The idea I had in mind was to not only incorporate a benchtop into the design, but to also incorporate storage as well, to allow us to store things such as charcoals for a barbeque/smoker and an induction cooker for cooking hot pot. The unit also had to be moveable, as if we needed to get the air con serviced, we needed to allow room for the HVAC technician to get easy access to the unit.

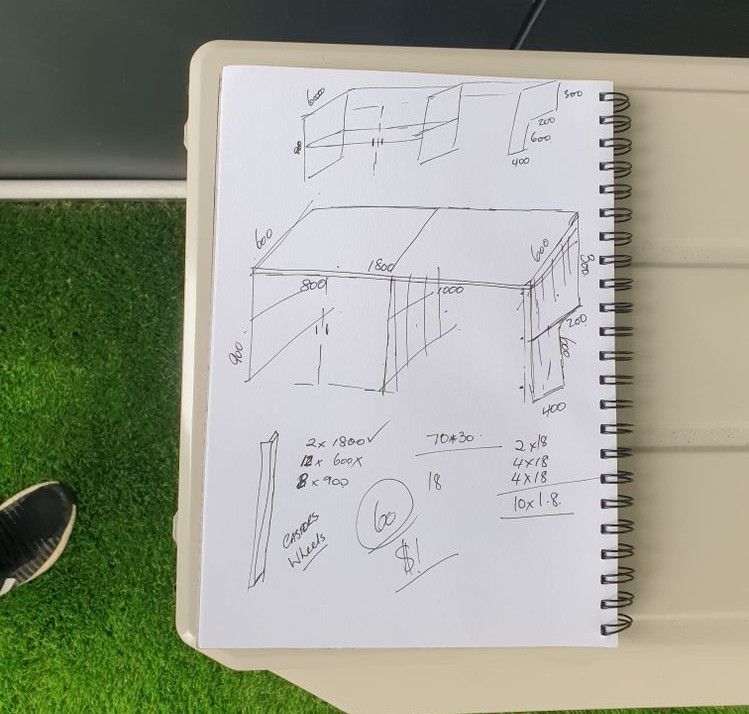

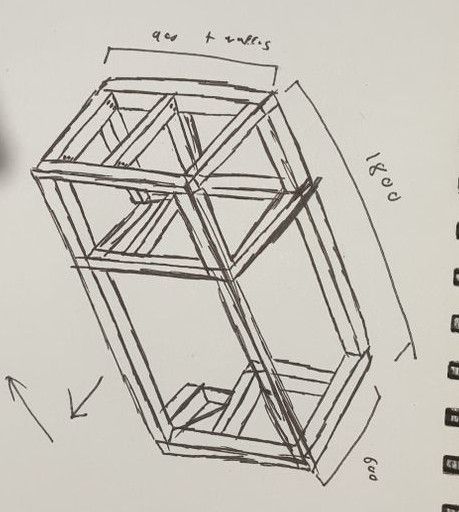

So, with that in mind, @hazesnow and I came up with these very rough plans. The first one is a general idea for the volumes, lengths and such for the timber we were going to use.

The latter was the design for the framing itself. The idea being is that the right-hand side of the frame needed to clear the huge stack of copper pipes and control cables.

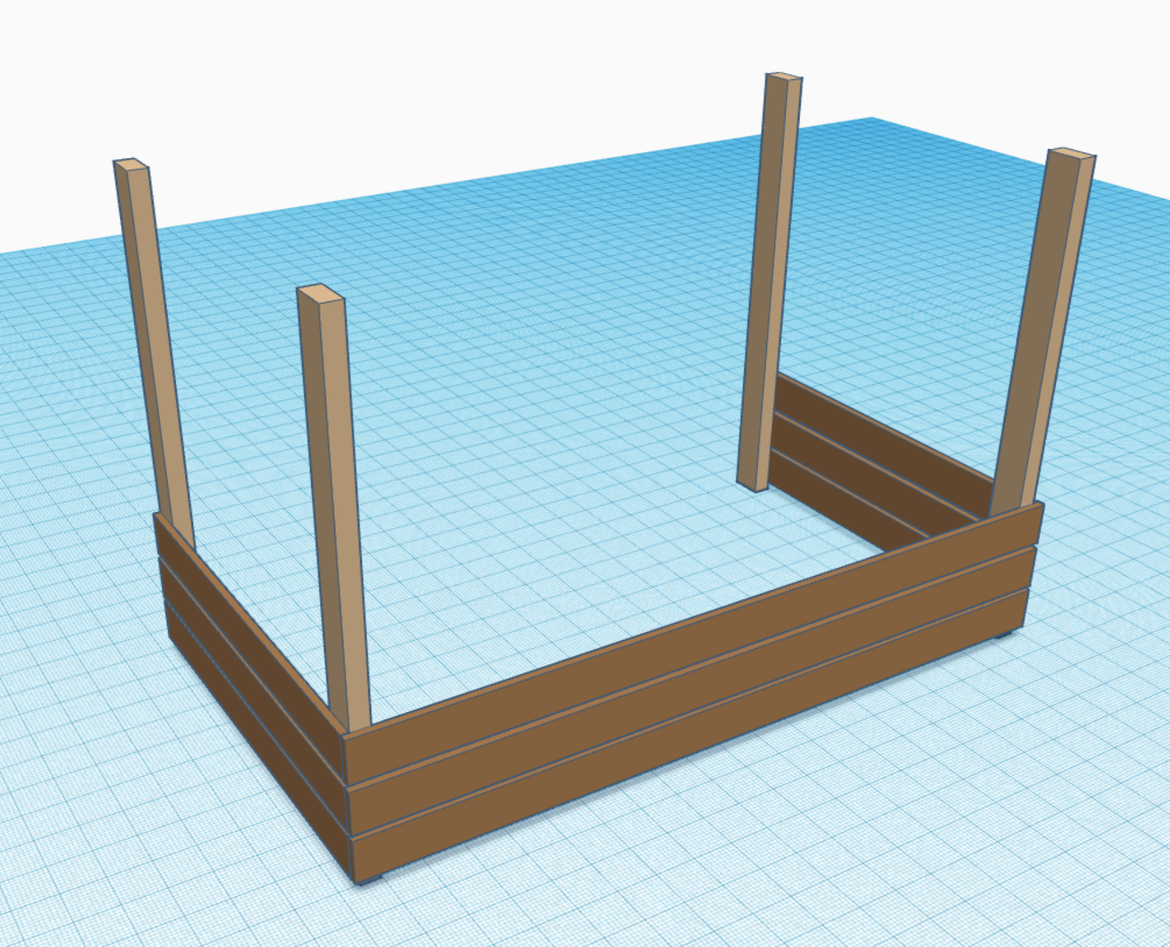

So, our frames were made from lengths of H3 treated framing timber. We purchased 5.4m lengths that were cut into 1800mm lengths to make it easy to move them in. These were cut on my stepdad's old Black and Decker Workmate bench, using a Zetsaw saw guide and a Zetsaw Japanese Kataba saw. We used a Kreg pocket hole jig to drill three holes in each piece and secured the joints using Gorilla wood glue. This first frame is 580 x 850mm in overall size.

To fit the shelf slats, we used another piece of H3 timber, only this time we cut into it by half the material's thickness to allow it to sit into the side of the frame. That cut is 35mm across the grain and 75mm with the grain. The parallel grain cuts were immensely difficult but we did manage to get them cut out. Once again, all done with the Japanese saw.

We then used the Kreg drill bit to counterbore two screw holes and used 40mm galvanised screws to secure the timber pieces together. We used a Makita impact driver to drive these in, which was pretty loud, but it saved us the hassle of potentially stripped screw heads.

This is the completed frame. We built two identical copies of these.

As for the right-hand side leg, this is how it turned out. This was essentially made to allow for clearance of all the copper pipes and control lines.

To assemble the first frame, we also only had two of these quick grip clamps on hand, so essentially we had to use them ingeniously. One is acting as a rest whilst the other is preventing the top brace from sliding out of place. We opted to use a scrap piece of 45 x 75mm Pine DAR, cut into two lengths to give us a little more "meat" when it came to securing the top on.

This here gives you an idea as to how little space we're working with here. The whole balcony is only approximately four metres by three metres in size, and most of that space is taken up by the coffee table and the two outdoor sofas. This is also why we need the frame to be manoeuvrable.

This is the left-hand side of the frame completed.

And this is the completed frame. As you can see, there's plenty of clearance around the unit to allow it to clear the AC unit at its current height, but we will be adding wheels to allow it to move around the balcony.

Our top of choice was an 1800 x 600 x 26mm SpecRite FJ Pine panel. Now, I absolutely love these panels due to their versatility. We've used these to put together our coffee tables, my desk, and the benchtop that @hazesnow and I built together. There was no need to cut this panel, as it was the exact right size to suit our frame.

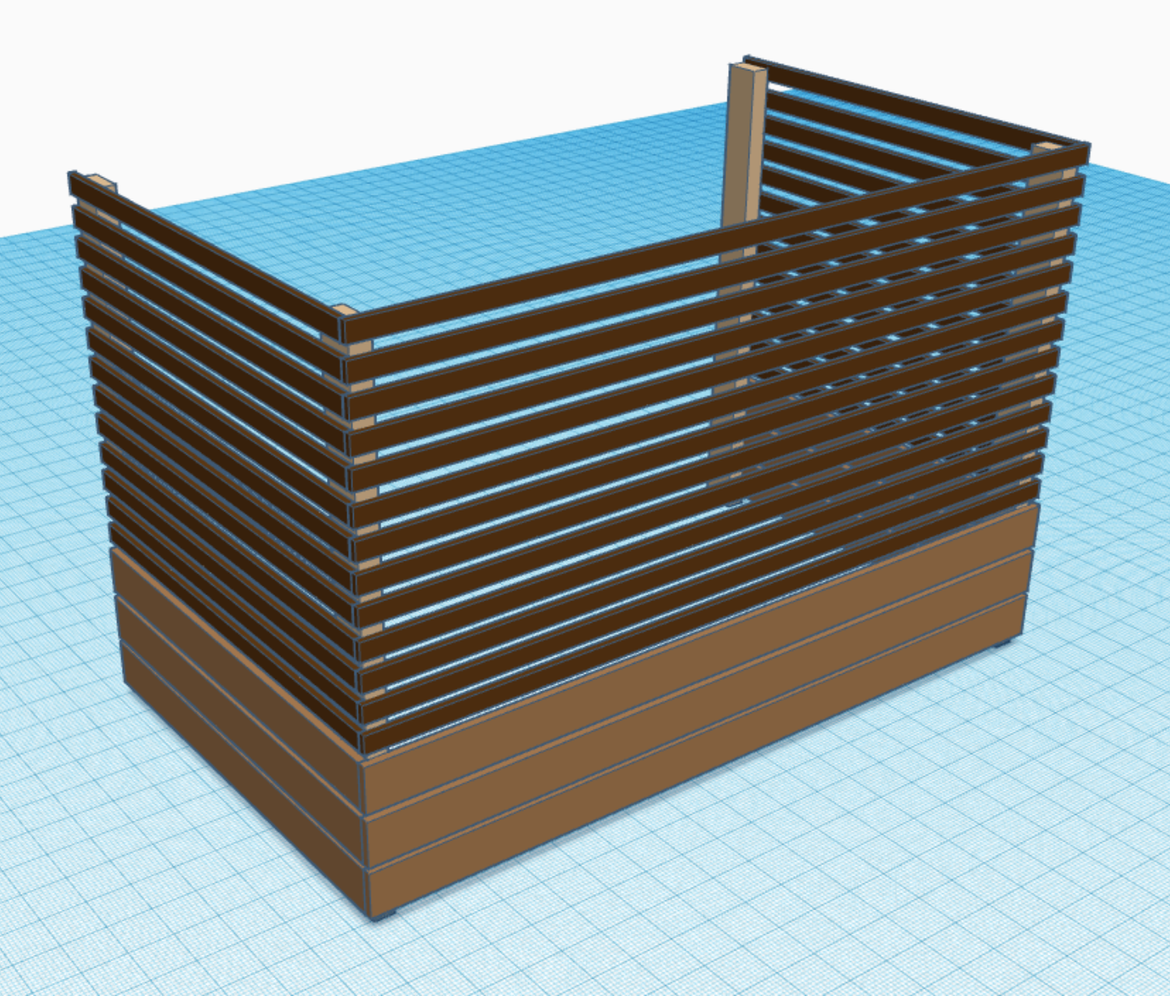

Now, on to the arduous and very noisy task of getting slats attached to the frame. These were attached to the back using counter-drilled holes in the back of the frame and secured with those same 40mm galvanised timber screws using our impact driver.

Of course, this didn't entirely go without a hitch. Some of our pieces did split a little bit, but these split pieces weren't so bad that we had to remove them entirely. The splitting happened in the earlier slats, and only because some of the holes were a little too close to the edges of the timber. We fixed these splits with some Gorilla glue mixed with some of the slat sawdust and filled the gaps nicely. With the rest of the slats, we took extra care to ensure splitting didn't occur.

As for the paint on the frame, we primed the frame with two coats of Dulux 1-Step Prep Primer Sealer & Undercoat, and then rolled on some Dulux Low Sheen Weathershield in Domino to match the wall and help it blend in. Cutting those back few slats was also a major pain. Hardwoods will be the death of me, but darned if they ever look nice when finished.

The shelf slats were cut to size and secured to the cabinet with screws going through the top. I know, nowhere near as pretty, but it definitely made the install a lot easier.

We decided to go with a multi-stage finishing process. Firstly, we soaked the wood with Cabot's Cabothane water-based varnish and let it cure, and then applied a marine-grade gloss varnish over the top to protect the lower layers from UV rays and the elements. Same goes for the top, too.

We then added these heavy duty 100mm castor wheels in the middle and rear of the unit, and added fixed castors on the front of the same kind. This gives the cover plenty of free movement. Now, the only thing we have left to do is to add a covering slat to the top of the frame, and add two DAR strips to either end to correct for the overall width of the unit.

Advice from the Bunnings team

Air conditioning condensers typically will have specifications on how close objects like screening can be placed.

The first thing to do is look up your model's installation instructions and determine the setback required for anything that might block airflow. Installing Merbau screening panels to block the view of your unit could be a more feasible option than a cover.

Once you've established the minimum distance requirements of the screening, you can begin sketching out how you'll build the cover.

We have created a rendering below how you could build a similar screening cover. 90 x 45mm treated Pine can be used for the framing uprights, treated Pine pailings for the skirting boards and Merbau screening for the slats. Climacoat screws can be used to join the skirting boards and slats to the frame timbers.

At a minimum, you'll need a handsaw or, preferably, a circular saw and a drill driver.

Please make sure to wear appropriate PPE whilst constructing the project, like safety glasses and follow the manufacturer's directions on tool use.

How to build timber screening

Experienced Workshop member Adam has posted this step-by-step on How to build timber screening and has included a helpful video as well as a full list of the tools and materials you'll need.

More inspiration for your screening project

Community member homeinmelbourne built this air conditioning condenser screen to cover an unsightly new unit. The solution includes a hinge so the screen can be opened when the air conditioner is in use so as not to impact on the unit's effectiveness.

Workshop member Rufaro used timber and lattice to build this handy enclosure to screen his hot water tank.

For more inspiration, check out our Top 10 most popular screening projects.

- Tags:

- Outdoor

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Afternoon @oheyitsbeano

Now that is a nice looking screen and benchtop! I was a little nervous when I recognised the benchtop you choose but then you say you have used it outside already ![]() Sold! I do like how you have maximised space and that would have been fun building it on the patio

Sold! I do like how you have maximised space and that would have been fun building it on the patio ![]() Well done!

Well done!

Dave

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects