The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Featured Projects

- >

- Concrete tabletop

Concrete tabletop

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

The project

I did a bit of research to find suitable materials for this project, which was to make a concrete top for my table. Here's a quick overview that others can hopefully find useful.

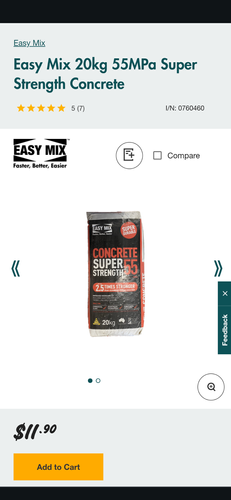

To make the form, I used this melamine. This is the concrete I used and this is the reomesh. I used WD-40 water protective silicone to ensure no sticking to the form. This is the silicone I used for rounding the corners of the form. I used this silicone scraper set for rounding the silicone in the form.

I cut the pieces of melamine and I made it so the concrete will be 40mm thick. The size was 2 x 1m. I needed 8 bags of concrete for this size.

Then I screwed the sides on. Then I ran a thin bead of the silicone around the edges and rounded them using the scraper set. This meant the corners of the tabletop would be nicely rounded.

Prior to adding the concrete, ensure the melamine is clean, then spray all over using the silicone spray.

Mix up the concrete according to the instructions on the bags. I had to add an extra couple of hundred mls of water to what it said to get it a nice consistency. Fill the form up ½ to ¾ with concrete. I left the edges a bit longer so it was easy to grab onto to pull them off later.

Then you'll want to vibrate it a lot on the sides and bottom. I used a reciprocating saw with no blade in it and ran it around the sides and underneath for about half an hour. You will see all the bubbles coming up. But otherwise, you can use a rubber mallet, or even a hammer. You may have to do it longer to get good results.

Then add the reomesh. I needed slightly more than just the one sheet for the length, so I cut a bit off another sheet I already had. Then fill up with the remainder of the concrete. After that, vibrate again for as long as there's still bubbles coming up. I smoothed the surface a few times and vibrated again. I did probably 45 mins or so of vibrating.

Then that's it for the casting. Just smooth the surface as much as you want (it will be the bottom once you flip it, so it doesn't matter too much). Cover it with plastic so it dries slowly. It might need a light spray each day for a couple of days. Then put the plastic back on.

Remove the sides and flip it and remove the top. The sides and top came off super easy. Then I wet it down and used 240-grit wet and dry to sand it, then 400-grit for final wet sanding. After that I sealed it using penetrating sealer. I used a microfibre cloth and poured it onto the table and just rubbed it round as much as the table would take before it wasn't soaking in any more. I'm super happy with how it turned out. It's really strong and doesn't have any flex when you lift it from the two ends.

More inspiration for your table project

Workshop member kel19 created their own D.I.Y. dining table using plywood sheet and dressed Pine.

Community member sammilne used three pavers to create this stylish travertine side table for just $66.

Check out our Top 10 most popular indoor furniture projects for more ideas.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

@markw looks great!well done !what type of concrete did you use?sorry the link doesn’t work

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

I'm really impressed it looks great. Did you use any additional additives or sealer?

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Morning @markw

How did I miss this project! Spectacular outcome, I have wanted to build myself a table top or benchtop for years and have come down to pretty much having it in my mind the way you described it. But you did it and have the pictures to show us how! ![]() It looks so professional its not funny,

It looks so professional its not funny,

Really nice work and definently filing this away for future reference.

Dave

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Thanks for joining in the discussion @Random_will. Let me tag @markw so he is alerted to your question about whether he used any additives. I note above Mark says he used a penetrating sealer - he might like to clarify exactly what he used.

Welcome to Bunnings Workshop. We're pleased to have you join the community and look forward to reading all about your projects and plans.

Jason

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Thanks @Dave-1

@Random_will I used only the penetrating sealer, which is pretty good. It will be fine to protect the tabletop from most things as long as any spill is cleaned up right away. But if something acidic or oily for example is left on the surface for an extended period of time, it could leave a mark. An epoxy sealer could be the way to go to make it completely resistant to any stains, but I wanted to keep the natural look.

I have a clear vinyl tablecloth that I can put over it it's being used for a kids party etc.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

I can't figure out how to edit the original post to add any more pictures, but here's a picture of the table after I installed the legs.

I used these screws to secure the legs to the bottom of the table https://www.bunnings.com.au/ramset-10g-x-32mm-black-ankascrew-10-pack_p0261459

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Thanks so much @markw. Great to get an updated photo. I have made it the hero image on this Featured Project article.

Jason

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Thanks this was really helpful. My slab tabletop is doing as i type this!

Couple of questions:

- how long did you keep it covered in plastic, and how often did you wet it while it's drying?

- which sealer did you use, and how much (do i need a 1 litre, 15 litre cab etc)?

Thanks!

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

@billbum I kept it covered for a few days, and just checked it when I thought about it really. Probably a few times each day, and gave it a spray with a spray bottle.

1ltr would be plenty for the sealer.

Let me know how it turns out when you're done!

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi @billbum,

A warm welcome to the Bunnings Workshop community, it is fantastic to have you with us.

For a high gloss concrete sealer, Crommelin 1L Gloss Wet Look Concrete And Paving Sealer should be a good option.

You can also check out @markw's original post here - Concrete tabletop project.

A number of questions have already been answered that might help you with finishing up.

Let me know if you have any further questions and please remember to share your project once finished. It would be fantastic to see what you come up with.

Jacob

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Thanks again.

One more question - which sander did you use or did you do it by hand? And which specific sandpaper (brand, type etc)?

I'm planning to pull the form off this weekend.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hello @billbum

It's fantastic to hear that markw's concrete top has inspired you to make your own. Let me tag @markw to make them aware of your question. It would be technically possible to use an electric sander, but it is critical that you keep the sander moving to prevent creating an uneven finish on the surface. Staying too long in a single spot could cause you to accidentally create a shallow dip on the surface.

Please remember to post an update, I'm sure our members will be keen to see how you made your concrete benchtop.

If you need further assistance, please let us know.

Eric

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

@billbum I wet sanded it by hand, I think I started with 400 and went to 600 grit. I found that wet sanding gave a nicer finish than using an orbital sander to dry sand.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Here is my (almost) end result. The sealer is still drying so it's a bit splotchy.

This is only a bbq work area, not a dining table so i cut a couple of corners which cost some aesthetics but very happy with the result.

1. I didn't wait for the silicone in the form to dry, it grabbed the edges which are a bit rough.

2. I set the form up on another, bigger, table so i couldn't access the bottom to vibrate, so there's a few tiny air bubbles. I filled the bigger ones in the centre with dune multi purpose filler so they don't catch food etc when I'm cooking.

3. I wasn't too worried about the finish but wet sanded it for 5 mins with a 320 grit sponge anyway and it is super smooth.

4. Used a natural finish rather than wet look sealer.

Vital statistics

1650 x 600 x 40

4 x 20kg bags

cost of materials and a couple of tools i didn't have approx $250

Thanks Markw!

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi @billbum,

Nice work!

It looks like a fantastic workspace for when you're barbecuing up a storm.

Thank you for the update.

Jacob

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Evening @billbum

The bbq bench top looks great, nice work ![]()

Love the Bunnings buckets showcase as well ![]()

Dave

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

We have just poured a white concrete kitchen bench top and have two fine cracks - any suggestions as to how we can fix?

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Afternoon @KylieP

Any chance of some photos? A couple of stand back at the benchtop and a couple of close ups would help us determine the best way forward ![]()

Dave

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Welcome to the Bunnings Workshop community @KylieP. It's wonderful to have you join us, and many thanks for your question about filling cracks.

I would suggest taking the cement dust from the concrete you used for the pour, mixing it with some water and then using your finger to massage it into the crack. This would be the most similar filler to use on the cracks. If the cracks are hairline, meaning that new material can't be inserted into them, that might pose a more difficult issue to resolve. In that case, you'd probably need to chase them out, opening them up so you can fill them.

Please let me know if you have any questions.

Mitchell

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects