The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Best Advice

- >

- How do you build a dedicated home theatr...

How do you build a dedicated home theatre room?

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

- How to choose a suitable home theatre room

- Selecting the paint or wall covering

- Additional room construction

- Flooring for your home theatre

- Lighting and equipment

- Acoustic treatment of the front wall

- Finishing off the front of the room

- Side wall acoustic panels

- The home theatre screen

- Front wall acoustics

- Rear wall acoustics

- Wiring your home theatre room

- The cables

- The equipment cabinet

- The front speakers

- Surround speakers

- The subwoofer

- Home theatre lighting

- Selecting the receiver and equipment

- The Blu-ray player

- Programming your home theatre system

Firstly to clarify, "a dedicated home theatre" means that the room you will be using will only be used for watching movies and perhaps some TV.

A home theatre can range in price from approximately $5000 - $500,000 and more! Some American home theatres I have seen cost over one million dollars!

This tutorial will describe how to build the lower end of the range.

Firstly you will need to find a suitable room. The bigger the better, but it must have four walls and a door. Open rooms connecting other rooms will not be suitable.

The other aspect of a suitable room is whether you need the theatre room acoustically removed from the rest of the house.

This requires an additional construction to the room to isolate it from the other rooms.

I will include briefly what needs to be done, but for the most part I will proceed on the basis that this will not be needed.

There are a variety of building materials that are used to construct rooms in a house. Timber or steel framing with plasterboard walls, or brick or concrete block walls. Each of them have their own acoustic values.

There is a lot to building a dedicated home theatre. But the end result is a very satisfying movie experience.

How to choose a suitable home theatre room

A good size room is desirable but not essential. The only room I had available in my own home only measures 3m x 4.5m, but as you can see the screen is almost wall to wall.

The side acoustic panels are before the parabolic diffusers were added, along with new carpet.

The main requirement is to use a rectangular room. A square room presents all kinds of problems with standing audio waves.

The ideal room has a ratio of Width x 1.6 Height x 2.6 Length. The height figure is not always attainable because most homes have a 2.4M.ceiling. The most important ratio is Width x 2.6 Length.

The window or windows in the room will need to covered with a blockout material. This only needs to be 3-pass blockout fabric. If it needs to be removed at times for air circulation, then a removable framing system will be needed.

Selecting the paint or wall covering

Any white or light colours are not suitable for a home theatre. The ceiling should be painted black. This will stop any reflections from the ceiling. The walls need to be either painted or covered with non reflective fabric.

I have chosen the latter for my new theatre as seen in the photo. The walls are covered with crushed velvet which helps to dampen high frequencies.

If you're painting the walls it needs to be a flat dark colour like a dark grey, or grey-blue or grey-green. The main thing is to keep it dark as possible.

Any light or lightness in colours will reduce the perceived contrast of a projected image.

Additional room construction

One other thing that can be added to the room is ceiling trays or soffits. I prefer the ceiling trays for the reason that if you're doing downlighting, it's easier to get to the back of the LED lights if you ever need to replace one.

The other benefit of having ceiling trays is that you can lay down acoustic fibreglass panels along the whole length for additional acoustic control.

As you can see in the photo, I have installed ceiling trays around the perimeter of the room.

Flooring for your home theatre

Whilst a polished timber floor might look nice, it's not suitable for a dedicated theatre.

The floor ideally needs to be solid concrete, but obviously this is not always done in the construction of a home.

Whatever your floor is, it needs to have a layer of acoustic under felt with a fairly plush carpet on top.

When you are looking at patterns for the carpet, keep it fairly simple with muted tones.

As you can see with my carpet, it's bright with a big pattern. This was a big mistake I made! It can be very distracting when watching a movie when the projector lights up the whole room in a bright scene.

Lighting and equipment

I made the ceiling light using strips of LED's mounted in a cabinet with an opal diffuser on the face.

One of the surround speakers had to be mounted to the door.

The large vertical panels are parabolic diffusers. They absorb low frequencies, diffuse mid frequencies and reflect high frequencies.

The screen is an acoustically transparent material purchased from the US.

All the main front horn speakers and the horn subwoofer are behind the screen.

The operation of theatre - lights, power, audio and video - is controlled by the single silver remote on the arm of the chair.

The projector is mounted in the room behind the back wall. The device next to the projector is a Dolby video processor. There is a built in cupboard across that back wall, so I have access to the projector by just opening the cupboard doors.

Also in this cupboard is all my theatre equipment. On the top shelf is the 7 channel AV Receiver. Next shelf down and to the left is the digital HD set top box. Next to that is the subwoofer equaliser control unit. Bottom shelf is the Blu-ray player.

If you look closely you'll see the little red sensor units attached to the equipment. The main sensor control unit is to the right (out of the photo) and all the sensors are operated by that silver remote in the theatre.

Acoustic treatment of the front wall

The next stage of the build is the acoustic treatment of the front wall.

This will dampen any reflected back waves from the speakers which will be behind the acoustic projection screen and absorb any reflected bass frequencies.

The amount of acoustic material needed will depend on the size of the room and what the echo effect is like.

The basic requirement is for the wall to be covered in 50mm acoustic fibreglass. This material has a 45kg/m3 density. It is also known as 703 fibreglass.

The same material is used for the bass traps. These are placed in the two front corners. Their construction varies from placing a 1m high, 50mm thick sheet straight across the corner to triangular pieces fitted into the corners and extending floor to ceiling. The latter is the most effective for absorbing bass frequencies.

The next stage is to build the framing to support the screen.

This can be done very simply by installing two vertical upright timbers extending floor to ceiling. They need to be 45 x 90 treated Pine. Attach a timber plate on each end and fix the assembly to the floor and the ceiling. The vertical posts need to spaced out the width of the intended screen.

When fixed in position, the intended height of the screen needs to be determined.

The screen needs to be as low as possible, approximately 300-400mm above the floor. Keeping the screen low will give you the most immersive effect of the action.

To affix the screen to the uprights, the simplest and most effective way to do this is to screw a piece of timber across the uprights at the height of the top of the screen, previously determined.

The timber to do this is a small skirting board timber that is 50mm wide and has a 45-degree chamfered on one edge.

This will be half of what's known as a "French cleat". One piece is fixed across the uprights and the other piece is fixed to the back of the screen.

When placed the right way, the two pieces interlock. This makes it very easy to remove the screen (as there are no screws holding it) to gain access to the speakers, and the screen can also be slid from side-to-side to centre it.

Finishing off the front of the room

With the screen in place, it's obvious that there's empty gaps top and bottom and at each end. These need to be covered to finish off the front of room.

Before doing that, in my own theatre I added a shelf across the uprights at the back. This shelf holds the amplifier for the subwoofer and the light controller.

With the covering being an open weave black cloth ( as can be seen in the photos ) the IR sensor unit for the lighting can be controlled by a remote through the fabric.

The covering top and bottom is made with a simple framework and covered with black polyester fabric. This material has an open weave and is stretchable in both directions.

The covered framing is attached to the uprights using Velcro cloth. This makes it very easy to remove the panel to gain access to the equipment on the shelf.

For the side open areas, I've just add some curtaining. The gap between the end of the screen and the wall was very minimal.

If your gap is more, I don't advise building any cabinets to fill that gap as some people do. It introduces another acoustic environment being an open face cabinet.

Side wall acoustic panels

The next stage of our theatre build is making or buying acoustic panels. To buy acoustic panels can become quite expensive and as they are quite easy to make yourself that is what I would recommend. If you have any D.I.Y. skills then they will be very easy to make.

You will need four identical panels for the sidewalls..Where they are to be installed on the walls I will describe later.

To make a panel you just make a frame out of 70 x 35 Pine approximately 450mm x 600mm. They can be larger if you have very high ceilings.

The frame is made with the timber on edge. That is, the depth of the frame is the 70mm dimension. This will give you enough depth to fit the 50mm thick acoustic material.

The front of the panel is covered with black polyester fabric. This is an open weave material which stretches in both directions making it easy to have the fabric stretched tightly.

The filling is a piece of semi rigid acoustic fibreglass 50mm thick called Ultratel. The glass wool is yellow in colour and comes in sheets 1200mm x 2400mm.

You just cut the material to fit snugly inside the frame and then pushed up against the front covering. The reason for doing this is to provide a space between the wall and the Ultratel material. This helps to improve the acoustic control of the bass sound field.

A further improvement can be had if you space the whole panel 50mm away from the wall.

You will need to make four identical panels. Two to be fitted on each side wall.

The position on the walls will be decided by two methods, but firstly the panels can't be positioned until you have the front speakers in place. This will determine the height for the panels on the wall.

The first step is to place a small mirror on the wall at a height where you will be able to see the reflection of a speaker. You will need to have someone slide the mirror along the wall while you sit in your centre seat. When you see the reflection have them make a mark above the mirror. This is your first reflection point.

The second reflection point is found in the same way. Have your helper slide the mirror along the wall after the first reflection point until you see a speaker in the mirror again. Then mark that position. Repeat the same process on the other wall.

Next with your front speakers in their positions, measure the height from the floor to the centre of the bass speaker. This will be the centre of each acoustic panel when fitted to the wall.

So now you have your first and second reflection points where to fit the panels.

The easiest way to mount them (considering they will be fairly heavy) would be using French cleats as described earlier.

The home theatre screen

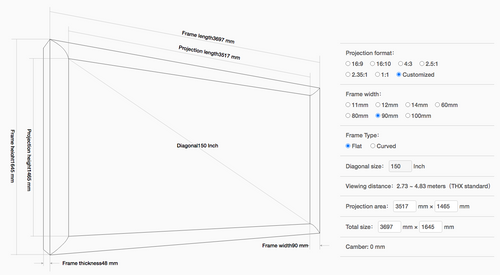

As mentioned previously, the screen will be an acoustically transparent screen for this theatre. The type of screen is CinemaScope screen with a ratio of 2.40:1, and for this exercise we'll say it is going to be a 100-inch screen.

If you were to buy an Australian commercially built screen of that size it will cost you approximately $1700 and going up to a 130-inch screen it would cost approximately $2700.

If you were to build it yourself using a US-made screen material (the same as the commercially made screen) and build a frame it would cost approximately $500.

The screen is fixed to those two uprights. A piece of timber 90 x 19 is fixed across the uprights at the height the screen will be mounted. The simplest way of doing this is to fix half of a French cleat to the back of the screen and the other half to the cross beam. This allows the screen to hang freely and gives the screen the ability to slide on the French cleat, making it easy to centre it.

The height of mounting the screen will be determined by your seating position. When seated your eyes should be level with screen a little less than a third of the way up from the bottom. This positioning will give you some image interaction for your viewing experience.

Front wall acoustics

The front corners of this wall are the areas that need the most acoustic treatment. Acoustic control known as "Bass traps" are what will be fitted to the corners. These bass traps are made in two different ways.

1. A similar design as the side wall panels, only these panels will have up to 100mm thick fibreglass wool and be a larger size panel 1500 x 600. These panels will be fitted across the front corners..

2..These will have triangular cut fibre glass panels which will lay on the floor and be fitted into the corner. Then the individual cut panels will be stacked on top of each other right up to the ceiling. The panels will be 600mm wide at the base with the angled sides to form the triangle 400mm long. This type of bass trap will be most effective in large rooms. They will also need some sort of framing to hold all the pieces together.

The next stage of the acoustics is the front wall itself. The space between the two bass traps will be covered with sheets of Ultratel, floor to ceiling. The sheets only need to be 25mm thick for adequate acoustic control.

Rear wall acoustics

This wall needs only minimal treatment and is pretty much the same for small or large rooms.

First requirement is a panel design similar to the side wall panels that fits across the back wall and is approximately three quarters the width of your seating area.

If you have 3 seats wide across the back wall then the panel will be approximately 1800mm wide x 600mm high with a thickness of 50mm. It will be positioned centred across the wall and midway the height of the wall.

It is advisable to also include corner bass traps. These can be of the panel type that fit across the corners.

With all these acoustic treatments the room should have no standing waves or unwanted resonances and provide a smooth sound field.

Wiring your home theatre room

In most situations you will need to run your wiring from the front screen area to the back of the room where your equipment is, or to an adjacent room. Either way you don't want see the wiring draped over the floor or even under the carpet. It maybe difficult to even lift the carpet and having bulky wiring underneath looks messy.

So how do you hide all the wiring? If you have soffit or ceiling trays you could run the wiring overhead, but you still have to bring all those wires down the wall to connect up to your equipment. This is what I did as many other home theatre installations have done.

These are the photos of my carpeted floor near the skirting boards.

Left hand side skirting board.

Right hand side skirting board.

As you can see there are no cables on the floor except that power board and cable.

If you look closely at the two skirting boards, you'll notice that the right side board looks a little bigger than the left.

Attached to the the right board is a white plastic extrusion. This extrusion is screwed to the skirting board and it has a cover which just clips on. Inside the extrusion are three channels which you use to run the cables through.

The cables are separated into audio, video and power. Separating the audio from the power cables is most important and this extrusion does that well.

The cables

There will be three 14ga twin-flex cables for the three front speakers and an RG6 coax cable from the subwoofer to the receiver. You may also have a transmitter sensor cable running from near the screen to the equipment and this can also be placed in the extrusion.

The equipment cabinet

This can be just a simple construction with shelves inside an open back box structure. On the base of this cabinet you need to put four casters, so the cabinet can be turned around. There will be times when you need to access the back of the equipment, so it needs to be mobile.

There is just one stipulation with this cabinet: don't put the amplifier or receiver inside the cabinet. They need to be placed on top so they have free air to expel any heat.

The front speakers

Choosing the front three speakers can be a major headache with the myriad of brands, types and models to choose from. There is one simple rule when it comes to speakers: pay as much as you can, and then some.

The speakers are the most important part of any home theatre system, so buy the best you can afford.

The first thing to consider when choosing speakers is: What is the size of the room? If it's a very large room then you wouldn't want to use bookshelf speakers to provide the sound. On the other hand if the room is fairly small, it wouldn't be a good idea to put in massive horn speakers.

When doing listening tests to different types of speakers, don't select any speakers that have a bright sound. Whilst they may sound good to the ears initially, they will become very tiring when listening for long sessions.

Another consideration to keep in mind when making selections is to choose speakers that have a good projection of sound, particularly if the speakers are going to be behind an acoustic screen.

Using my own situation as a guide, I have an acoustic screen in a small room. The screen is almost wall-to-wall.

The type of speakers I use for the three fronts are Folded Horns. The drivers in the speakers are a German brand and the cabinets I built to a folded horn plan. These speakers are quite powerful and project sound very well. They also have a mellow sound which is never tiring, even after three-hour movies. This type of speaker would be good for up to medium size rooms.

At the other end of the spectrum, commercial cinemas use massive open face horn speakers, usually standing about 1.8m and taller. This size of speaker is what is needed in such a large room. The horns provide the mid-range and upper frequencies. The bass is usually a simple bass reflex system using four 12-inch or 15-inch speakers in each cabinet. If you have a large room then I would suggest you look at a smaller version of these.

A single 12-inch or 15-inch bass speaker in a folded horn design with open faced horns for mid and highs will provide excellent sound for a large room. The only downside of this is that such a design commercially built will cost a lot of money - one or two thousand dollars for each speaker! The upside is that if you're a handy person you can build these type of speakers for a lot less. There are kit plans available on the web. All you have to do is build the cabinets.

Surround speakers

The surround speakers are not quite so important as the fronts. You can use bookshelf-type speakers and even a different make than your front speakers. They only need to be a two way system ( bass-mid and tweeter) with the bass-mid speaker up to approx. 10-inch in diameter.

The reason for this is that you don't get a lot of full-on sound as with the fronts, you get mainly ambient surround sound effects with the occasional sound of a jet plane flying overhead from the back of the room to the front or some such similar thing.

When it comes to mounting your surround speakers, they should be directly opposite the ears from your seating position and with the main driver of the speaker approximately 300mm above your head.

If you have a very wide room then the speakers can be mounted 1800mm above floor level.

These locations are based on a 5.1 system. Other systems require a different set up. With a 7.1 or 7.2 system you will have surround speakers on the back wall and side walls.

All surround speakers need to be the same make and model. They should be mounted at the same height as the side surrounds and spaced within the width of your seats.

The subwoofer

Like the main speakers, there is a huge range of commercial subwoofers, starting at about $900 to many thousands of dollars. Again the simple rule is to buy the most expensive that you can afford.

My only choice was to build my own. But where do you start and how difficult will it be? I discovered a website that has a whole range of D.I.Y. subwoofers and for a small fee they will actually send you detailed plans on how to build them.

I did this many years ago and built my first subwoofer. Once the timber had been cut to size (and they tell you what size each piece should be) it was just a simple matter of building the box and installing the driver. The end result turned out very well and that subwoofer lasted many years.

My current subwoofer a much more advanced folded horn subwoofer was built from plans from the same website. The cabinet was quite complex compared to my earlier subwoofer and about three times the size. The incredible thing about this subwoofer is that it only uses an 8-inch 600W driver and yet it can shake the walls in my theatre. But if you want to feel the bass thump against your chest, then you can also use a 10-inch driver instead.

The other thing with building your own is you will need a separate amplifier to power it. Plate amplifier are used to power subwoofers and you can buy these online. It just needs to be a 240V one with approximately 400W output.

Home theatre lighting

Lighting can be a very personal thing and everyone has their own idea on lighting choices. There are three main aspects to the lighting:

1. Overhead lights

2. Sconce lighting

3. Downlights.

It is advisable to have a main overhead light of some sort so when you first enter the theatre you can turn on some lighting. Most times when you enter the theatre it will be completely dark when you first go in, so you don't want to be fishing around to find a light switch. I have a wall mounted sensor switch just inside the door that you just run your hand over and the light turns on. It also has a remote that I can use to switch off the light when seated.

I don't use sconces in this theatre because the diffusers take up a lot of room. There is a huge variety of wall-mounted sconces, so it's just what appeals to you. They are there for just aesthetics.

Downlights are probably the most used and needed in home theatres. They can provide lighting down the screen if you have some sort of soffit or ceiling tray above the screen. They also emphasise the screen and its size, and give a dramatic effect to the overall front area.

The other location for downlights is along the sidewalls in either soffits or ceiling trays. Spaced evenly along the walls gives a nice effect and illuminates the room very nicely.

All of these lighting systems can be controlled combined or individually.

Selecting the receiver and equipment

There is a huge range of receivers to chose from and it can be quite confusing. The first thing to take into consideration is the size of your room. If it's a very large room then a receiver with 50W/ch is not going to do the job. Conversely, having 200W/ch in a small room is a bit over the top. Generally a receiver rated at approximately 150W/ch will be suitable for most rooms.

There is also quite a number of different brands to choose from. Some are very good for theatre sound but some brands are more suited to stereo music - they generally have a more mellow sound than home theatre receivers.

There has been a lot of controversy over the years as to whether different brands of receivers have their own sound or not. Personally I believe they do after hearing many brands over the decades. On that basis, my choices for a receiver for home theatre are Yamaha, Marantz, Pioneer or Denon.

Generally speaking, if your budget for your whole home theatre equipment was $10,000 then you would allocate approximately $4000 for all your speakers and $2000 for the receiver. The other $4000 would be used for the Blu-ray player, digital TV tuner, subwoofer, equaliser, lighting controllers, wireless remote extender, programmable universal remote and ancillary power blocks and wiring. That gives you an idea of what the ratio of costs are within a budget. From there you can adjust your own budget.

The Blu-ray player

This would seem not to be of any particularly importance in the price of the equipment selections, but that would be very wrong. You can pick up a player for about $250 that would do the job, but considering that there's a brand of a player called Oppo that sells for a minimum of $1000 and up to $2200, there has to be a reason why this player is so expensive compared to the $250 player.

Well, there is. I won't go into all the specifications for these players, but suffice to say these are the "state of the art" Blu-ray players and are recognised as such in most Western countries. If you have the money, buy one. But if not, there are some players that will be almost be as good for a lot less money.

One brand that is accepted as the poor mans Oppo is the Panasonic range. Their top-of-the-line model is priced at $1900, but you can still get excellent quality in the lower end of the price range.

I bought one for $550 and the picture quality and sound quality is excellent. I've had numerous Blu-ray and DVD players over the years and this one is the best ever.

One word of advice..When installing any Blu-ray players on a shelf or in a cabinet, always place a rubber mat underneath. This will keep the unit stable from any vibrations, particularly those loud deep bass sounds. Generally the feet that are on the player will not stop the player from vibrating.

The next and final stage of the dedicated home theatre is the programming of the whole system. This will be the most complicated aspect of the whole system. You will require computer skills and a ready understanding of how programmable universal remotes are set up.

Programming your home theatre system

This will be the last stage of the whole home theatre system and is perhaps the most complicated aspect of the whole setup.

To be able to press one button on your programmable universal remote for "Watch a Movie" requires numerous operations from the original remotes and numerous sequences programmed into the universal remote. It takes a lot of work and some technical knowledge to do all this, but the end results are well worth it.

This is the usual scenario..You are sitting in your chair with universal remote in hand and you press the button "Watch a Movie".

For this to happen:

1. Your AV Receiver is switched on and is then set to BD (in this case)

2. Your Blu-ray player is switched on (A BD previously loaded)

3. Your projector is turned on and set to HDMI with aspect ratio set to 16:9.

These three aspects are programmed in to your universal remote by you using the disc that was supplied which you have loaded into your PC. And then with the image on the screen the start image of the movie is shown and you make your selections.

You then press "Play". The Blu-ray player begins to play. The projector changes the aspect to 2.39:1. The light controller gradually dims the theatre lighting and you sit back and start to watch the movie.

To do all this you need a good programmable universal remote. Logitech Harmony remotes have been the universal choice for many home theatre systems across the world. Logitech has been "The remote" for many decades. Sadly, Logitech is not making any more remotes. They are continuing to provide programming for most of the range, but when the stores have sold their stock there will be no more.

There are alternatives but I can't comment on how they perform. I've had several Logitech Harmony remotes over the decades and they always do a good job. A little while back they changed their operating program completely and I had to start all over again learning how to program my current remote. Unfortunately they left some things out of the new program (why I have no idea ) which has made it even more difficult to have everything operating correctly. Because this is very complex and individual to plan programming, I won't include any here. If anyone needs help to do this, you can let me know with a post.

I hope I have given all of you the help you need to set up your dedicated home theatre. - Prof

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hello @Prof,

Thank you for this awesome article, really fantastic information.

Can you please link to the US screen material supplier you used, please.

Also have you got an idea of the material/timber/design/guide link you used to build the screen frame, please.

Best Regards,

Garry.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi Gary...

Thanks very much for your kind words of appreciation..

The screen material I used came from this Company..

The type I used is called "Centre Stage"

The framing material was that grey painted timber (can't remember the name) very stable composite timber..

I used 70x19 for the frame..and made it just like you would if you were making a flat picture frame..

I also used bracing in the corners and then covered the frame with black velvet..

Then the screen material was then stretched across the back of the frame and attached with heavy duty staples..

After that I screwed a low profile skirting..the type that has a chamfer on one edge..to the top length of the frame on the back to have half of a French cleat which is how the screen is hung..

Good luck with it all and if you need any further help, just let me know..

Regards,

Prof...

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hello @Prof

Thank you for your response and for the link, semourav are good, Ive checked their screens before , i believe centre stage XD is what you refer to, but i've seen on their website that they possibly do not ship that anymore.

Unfortunately, i cannot find that gray painted timber you refer to, all i can see on Bunnings is the very heavy Merbau or pine, or fence/decking timber. If you remember any further details of the timber, please let me know.

Bracing at the corners you mean that you used timber pieces at the back of the corners to reinforce the corner right? By the way, how did you join the corners after cutting them into 45degree angles as a picture frame, by glue or just the timber bracing at the back or both?

Sorry for all the basic questions.

The you just wrapped the frame with velvet and stapled at the back.

So you just stretched the screen material at the back of the frame and stapled, not stretched around the frame and then stapled, correct?

I know its a bit of an ask, but if there is any possibility of some photos that will be great, or if you come across another guide with photo/video that followed the same method as you, that will be really handy.

Really appreciate your insight.

Best Regards,

Garry.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi Garry..

It would seem that there have been a few changes to products and supply since I made my screen..

I was surprised to hear that SeymourAV aren't shipping their screen material anymore..

And the timber I used for the frame doesn't seem to be available anywhere either.!!

The only choices I see is that there is now a material called "Eco Deck" it's available in 67mm wide or 137mm. wide and is 22mm thick..

It would obviously be a strong board and wouldn't need any bracing and I'm guessing it would be quite stable as well...

There is a Company in Australia that sells screen material..They may have have something like the Centre Stage XD..

This is there URL..https://www.projectorscreens.com.au/diy-screen-fabric/

If I remember correctly there prices are fairly high for screen material..

There is an alternative that's very popular and is used by a lot of home theatre builders.. called Spandex..

It's readily available from fabric stores and is very cheap..You can get it in various colours..but white and grey would be your choices..

When making the frame I glued and screwed the mitre joints with two screws in each corner..

I think I misled you how the screen was made..sorry for that..my memory is not good as it used to be..

This is what I remember now..

The MAIN frame was made from that composite material only it was 90mm. wide..

That frame had the screen material stretched across it and stapled on the back..

The SECONDARY frame was made from the same composite timber and that was 70mm. wide..

The velvet was wrapped around that frame and glued and stapled on the back..

Then that frame (being the border) was screwed to the main frame..

Here are a couple of videos on how to build an acoustically transparent screen..

https://www.youtube.com/watch?v=5_qYMRmjtT0

https://www.youtube.com/watch?v=7b3f3JcHQAU

One thing I would advise you to do is to make the screen with a 2.40:1 ratio..

Blu-ray movies are made in this ratio today. so you get the full width image..

When I watch TV on the screen the image automatically reverts back to the 16:9 ratio..

Let me know if you need any further information..

Regards,

Prof...

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hello @ozieboy

@Prof's recommendation is excellent as always. Using Ekodeck for your framing is definitely worth doing as it is more dynamically stable than wood. Although the capacity to move is still there, this will only happen when it's exposed to the hot temperature of the sun. I recommend making quick sketch of your frame and sharing it with the community. We can then have a closer look as to how you plan to put it together. We'll then be able to make recommendations on how to assemble it.

If you need further assistance, please let us know.

Eric

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Thank you Prof, thanks for the detailed further explanation of the build process and the material.

Eric, I have the following material:

https://www.bunnings.com.au/133-x-18mm-l-m-cladding-cedar-shiplap-t-g_p0100390

I can cut this to size, may be around 70 or 90mm after cutting both the clip-in sides. If you believe that its not as good as a material as the Ecodeck then may be i can use this to practice at least?

I will be doing a rough sketch of the frame I have in mind and share it here. I have time on my hand for this project, so it might be slow for updates in this forum, sorry.

Best Regards,

Garry.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi @ozieboy

I've been thinking about your screen frame last night and it occurred to me that you'll be placing this inside a room that has a very stable temperature in it. On the condition that it won't be getting extreme afternoon sun, odds are that the cedar will stay stable.

Let me call on our experienced members @TedBear and @JoeAzza for their recommendations.

Please keep us updated with your progress, we look forward to seeing your screen frame plans.

Eric

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Eric, what do you normally use to render a design/plan, I mean what application on the computer etc?

The other hurdle that i am contemplating to get my head around is how to make long straight cuts into my board (the cidar cladding board) as I will have to take both sides off little bit to cut the sides off to get either a 90 or 70 mm board?

As the length is about 3.5M, I will have cut the 3600mm boards that I have into a long straight cut.

I have 165mm battery operated circular saw already and I purchased a multitool, reciprocating saw and a planer over the weekend from bunnings. I also have orbital sander, detailed sander and drills etc from a few months back from bunnings, all battery operated. So thats the tools that I have.

I am also concerned that the cidar that I have when but to a 90 or 70mm size with that 3500mm lenght, might not be stable and will be wobbly, but before i get to that stage i need to get the cut done first and see how it is.

Over the weekend, i went to bunnings and saw the pine timber and most lenght i could find is 3m, I also checked out the EkoDeck and its probably not what i had in mind and seems too heavy and not fit for the purpose. Anyway, i want to try with the material that i have in hand first.

So, any tips for cutting that board in a straight cuts, please.

Best Regards,

Garry.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi @ozieboy

I use Sketchup to render my designs, it's a handy tool as you can build to scale in the drawing software.

In regards to cutting straight, I suggest using a straight piece of steel or a timber piece as a guide for the saw. I recommend using clamps to keep the guide in place. I recommend drawing a cutting guide on the timber so that you can line up the saw guide on the timber piece.

Here is a link to our best advice: How do you make long and straight mitre cuts?

Let me call on our experienced members @Adam_W and @TedBear for their recommendations.

If you need further assistance, please let us know.

Eric

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects