The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Bathroom and Laundry

- >

- Re: Laundry retrofit

Laundry retrofit

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Laundry retrofit

I wanted to retrofit my laundry and reuse products as much as I could without purchasing any new materials unless needed.

Originaly I had thought of putting in a shower but that was going to be problematic as the centre of the laundry doesnt even have a floor waste point. So $$$$ changed what I would do.

I really like the idea of being able to dry clothes inside especially during winter but don't like the idea of a dryer chewing up buckets of money to run. I wanted to factor in a solution for that also.

Materials

Liquid nails

Kinetic Tap Y fitting

SmarteX-C connector for laundry hoses

Uni-Pro Smooth coat filler

LED 1.2m light fitting

Matt Black door handles

Tools

Circular saw

Spirit Level

Tape meausre

Bucket....

Round File

Clamps

Steps

Step 1

The first step was to repair the crazing of the ceiling. Moisture and a bad paint job previously had caused the paint to crack and peel. I scraped all the loose flaky bits off and then sanded smooth the edges. Once I had done that I filled in the paint height difference with an interior filler. I did this in 2017 and its still going strong 6 years later. No signs of cracks or puckering. The darkness in the photos is from my poor phone camera and the old lighting not working.

Really didn't want to replace the ceiling so thought I would give it a go to clean it back and repair. At this point I wasn't thinking about replacing the light.

The paint had peeled from the surface in huge flakes.

This would have been directly above the dryer with the previous owners.

I kind of regretted starting it as my arms would ache like crazy from working over my head.

Once scraped clean and sanded I filled in the dips with a fine putty.

This putty worked extremely well and was incredibly easy to sand.

Looks messy as but was smooth to the touch.

So much sanding.

Time to start the painting

So much nicer.

Painted the walls and you can see the old cream colour really show up.

Yeah the light had to go.

Much brighter and clean feeling.

Step 2

I was working out door angles, Windows and what would fit. For me sketching it out really helps to bring all the parts together and spot any issues. The ripping out of existing laundry sink and fixing old damage was next on my list.

Time for this one to go.

Found a very low rise LED light.

Seriously didn't realise how bright it was going to beam. The Future is so bright I gotta wear shades comes to mind...

Bunnings didn't have such a large range of LED lights as it does now so had to go outside ![]()

Old laundry sink is about to go.

It was a pain in the neck to remove. The previous owners had tiled over the flange on the back side of the metal sink to hide the damage to the wall. I couldn't see any screws and could not figure out for the life of me how it was still staying attached. Once I looked closely I started shaking my head. You can see the long term water damage that had happened.

These tiles were covering the water damage.

Dodgy bro inc strikes again.

The cowl of the tap had been cut with a grinder to make it fit..... My head boggles.

You can see how close the taps are to the window trim. I removed all the old "Water check" material that had been used in the wrong place.

Step 3

Next stage was to replace the backing area that I had cut out with some villaboard and also put on some door handles for the two doors in the room. The Villaboard I was stressing about even tho the Bunnings staff had told me how to cut it. Turns out they nailed it! It was so easy I couldn't believe it! I also started out mapping how I would lay the new / reused benches in reality, compared to my sketches.

I removed the old door handles and then realised the new ones needed a different centre cutout... Ugh. Looking back at it I could think of a few different ways to do it other then filing and trying to drill it out..

Testing out to see if it fits.

What the hole ended up being ![]()

The sheet of villaboard I was using, I had to cut it to size and also cut a section out of it. The instructions I received from Bunnings worked so easily. Like cutting/scouring/snapping a plaster sheet.

Once trimmed to size I had to drill the holes for the tap fittings. I used a diamond bit hole saw

Sorry for the blurry shot but I was cheering as the holes were true to location and worked so well.

I put down tape so the drill wouldn't want to "travel" so easily. There is no centre spindal on these type of drill bits and I had not used them before.

Like a bought one... I am still smiling even 5 years later!

I glued it in place and nailed it (pretty sure I drilled pilot holes as I was worried id snap it by driving a nail through it)

Laying out the plinth so I could get an indication on "how to" and would my ideas work for fitting out the room. It change dhow I decided to go forward.

Step 4

Time to start retrofitting some bench carcasses I had recovered from work. They were being thrown out and I thought why not!

I hadn't factored in the washing machine needing to sit on the floor, I hadn't thought of dead space in a corner, if the cupboards go around that corner.

I had considered widths for bodies passing, etc. These all showed up when I laid out the bases just to get an idea of upper body movement in the room.

Removing the back so I could cut down the "thickness" of the shelves. from 600mm down to 350mm I think?

Slow dripping was annoy so came up with a temporary solution

Old carcass before the trimming

The rejigged plinth. It worked a dream.

Slowly getting the pieces placed as I wanted them. I made sure I left more space either side of the washing machine in case the next model bought might be a different size. I left 80mm all up extra

The new revamped width. I didn't want to put doors on these as there is really no space to be able to open them and its a Laundry so shelving I thought would be a good workaround.

Placing the new timber top

Figuring out the tolerances and how close I want to go to the edge.

Cutting out the hole. Really should have taken the whole piece outside to cut as almost had an injury being in a confined area. Rem the circular saw can "KICK" you can see the mistake on the left hand side of the hole.

The kick of the saw as it bit into the timber. Need more practice or how to lessons. Silly mistake

I didn't go all the way through but could have been me because I didn't take the timber outside to cut. It can be filled with timber putty so all good but blood was pumping.

Trying to figure out the clamps in such a tight fitting area. I have done a sink before and forgot how fiddly they can be. also my spacing was close.

Yeah, stood there for ages working it through in my mind.

Step 5

The next bit was oiling and joining the timber sections together. I gave it three coats all up and haven't needed to oil it in 5 years since. I should probably do so but no water gets on the surface as it is.

Making sure that the bench was going to be level.

Trying to figure out how to make the thin side of the timber next to the sink strong after cutting it close. (due to the size of the sink)

Strengthening strips...

The small edge being strengthened. One thing I didn't allow for was the spacing for the edge clamps of the sink. They just fitted otherwise I would have been in trouble.

I used the middle part of the sink I cut out for the end of the bench. This was filling was for a cut on the timber when I had measured it wrong.

The timber bench top I had bought from Bunnings discounted as it had some rough spots like these. I didn't mind as that was what I was after for this retrofit of the laundry. Reuse as much as I could.

Finally in place! Right down to the temporary fitting so I could stay clean!

Starting to oil the bench, I didn't want a lacquer as it degrades over time I figured.

The timber really shone through with the oil applied.

The cut that was fixed with timber putty.

Three coats in and water beads nicely. It still beads 5 years later.

The join is from the piece that was cut out for the sink and then reused to extend the benchtop. Its smooth to the touch tho the grain didn't match. I was happy with it ![]()

Without the door and shelving added

Marrying up the existing plumbing and the new stuff. Back to Bunnings to buy adaptors. I hadn't thought it through before hand.

All connected and working. Had a little leak at first from a perished rubber O ring but replaced it and no more drips.

Step 6

Last stage was tidying it all up and putting back the shelving and storage of tools ect. This was a long job over 3/4's of a year as outside projects were taking priority. Still to do is the splashback of which I do have the tiles but have never actually tiled as nerves is what is stopping me lol

Door fitted, Shelves fitted and buckets "de-loggoed"

I am really happy how it came together. I should "smooth" the sharp corner near the washing machine but thats all I would change.

I had wanted to do an "air dryer" for years. This is the spot I had in mind. It would cost $$$ in electricity to run a normal air dryer for clothes, this way it will cost only a fraction of that. I bought a floor fan just for the job and it sits on the bench to the right of the washing machine.

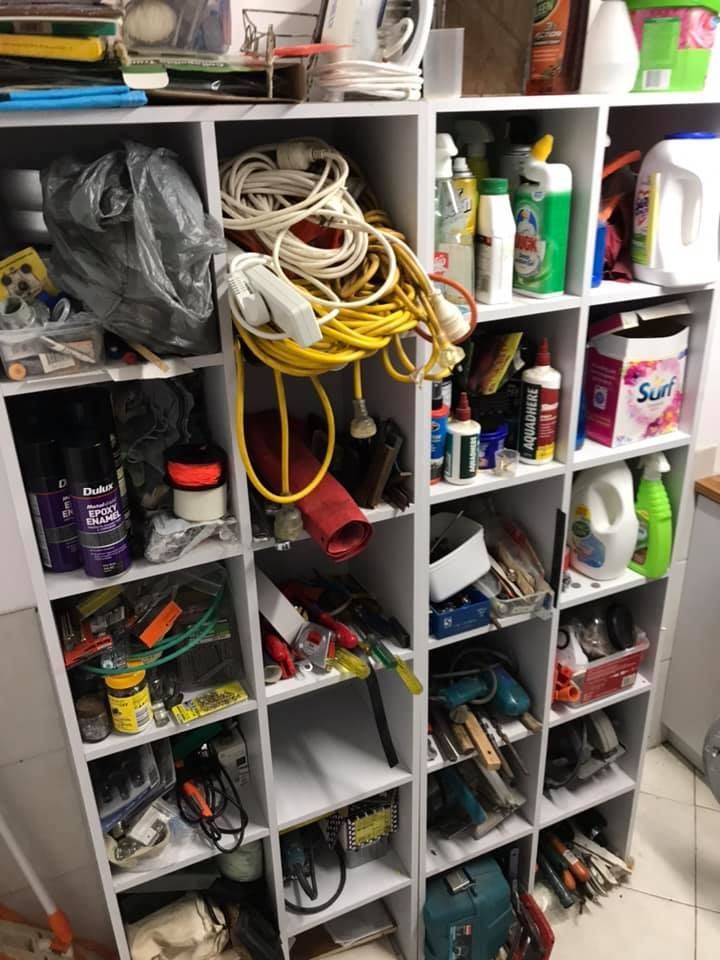

Reused a Storage rack system that was being thrown out at work. I didn't fasten it to the wall at the base as did not want to drill through the tiles on the wall. But did fasten it in six places further up.

Just a normal clothes hanger. It sits in the channels nicely and can be expanded out or shrunk if necessary

Flatter to give more space. It really works well with a bench fan sitting next to the window.Three hours of the fan and the clothes are almost dry.

Yep more recycled hutches.These were slated to go to the tip. Fairly heavy and very solid. One thing with tiled floors, don't drop heavy tools on them. I need to get myself a rubber mat. Also they have become stuffed with 5 years of little used items so its about time to clean the shelves.

It was a long project and was glad when I finished it (except for the tiling) The laundry is a very functional room now. Its my tool and laundry storage plus drying room.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laundry retrofit

Hi @Dave-1

That is a beautiful laundry retrofit, I'm sure the extra benchtop space has come in handy. Have you ever found the time to tile the splash back?

Thank you for sharing such a wonderful project.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laundry retrofit

Sad to say no 😕 lol Its "On that list" I tell myself that its a rainy day project ![]() I have the tiles, think I even have the glue but nevousness plus being distracted just adds up to that "on the list" job. Maybe we should have a week of teh year where we only focus on the "On the list" jobs

I have the tiles, think I even have the glue but nevousness plus being distracted just adds up to that "on the list" job. Maybe we should have a week of teh year where we only focus on the "On the list" jobs ![]()

Thank you for the compliment and yes the bench and sink really work well especially with drying clothes! ![]()

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laundry retrofit

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.