The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Whole of House

- >

- Re: Small D.I.Y. projects to do over the...

Small D.I.Y. projects to do over the holidays?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Small D.I.Y. projects to do over the holidays?

If you’ve seen the Top 10 most popular projects shared on Workshop this year, you’ll know that you don’t need a massive budget or extensive D.I.Y. experience to start improving your house or garden.

In fact, small and achievable projects are among the most popular on the site. It's not surprising, considering taking the time to carry out a simple fix or build a quick solution can sometimes make life easier and better. Just ask @DIYgals, who recently built this baby monitor stand, or @homeinmelbourne, who shared a budget screen door refresh.

The upcoming year-end break is a great opportunity for many of us to attempt those small D.I.Y. projects we've been putting away. Of course, I want to be able to spend time with my loved ones and relax, but I also don’t want to miss the opportunity for some small and simple projects while I'm off work.

So, I’ve decided to take inspiration from @lifestylebymari's spray painted tapware and use spray paint to give my bathroom a quick refresh. Hopefully I manage to achieve a decent result.

Are you planning on tackling any D.I.Y. projects this year-end? Do share your plans below – you might just inspire someone to improve their home as well.

Akanksha

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small D.I.Y. projects to do over the holidays?

I can't wait to start repairing some old cracks in our plaster. Once those small repairs are done then we can get onto the bigger task that is everyone's favorite job - PAINTING! But honestly after renting for so long and now that we own our first house I am more than thrilled to be able to paint some walls. Is anyone else going to be tackling a paint project?

Katie

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small D.I.Y. projects to do over the holidays?

One of the things I'm still most thrilled about is how I moved this latch on my gatepost. It only took a couple of minutes, but it has made a huge improvement to my daily quality of life.

Over the years the gatepost had sunk by a centimetre or so, and it had become a battle every day to get the latch open and closed.

Eventually I decided enough was enough. I went and bought a Ryobi 18V drill driver and a little nut setter, took out the screws and the latch, drilled new holes and put the latch back on (still with the same old screws, I think).

Going through the gate has been a pleasure ever since, and I've used the drill driver for so many other things that I don't know how I ever survived without it.

Brad

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small D.I.Y. projects to do over the holidays?

How exciting! I am sure you will do an amazing job and cant wait to see the turn out. And happy DIY ![]()

Mariana

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small D.I.Y. projects to do over the holidays?

Morning @BradN

"I love how great it feels to get even the smallest jobs done."

Ditto that thought.

This was Monday's small accomplishment. A repair attempt to keep a toilet roll holder horizontal.

A Cosmo product from Bunnings. Never again.

Looks innocent.

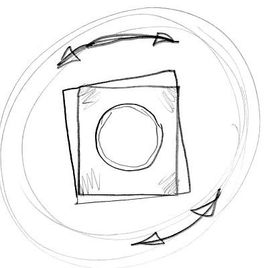

The circular flange fits over a square section in the die-cast alloy arm.

Now all looks fine - and it's almost impossible to see with the naked eye or even with a close-up photo - but there's movement between the squares which equates to around 15 degrees. This makes the arm move between horizontal and the toilet roll wanting to fall off.

Exaggerated diagram of the movement I'm on about.

What's suppose to happen is a M6 bolt with a washer holds the arm rigidly in place. It doesn't.

It's even over time worn down the metal with the regular movement (bowel humour).

So I drilled further into the threaded area and tapped more thread for a longer M6 bolt with a bigger head. But I found the head interfered with attachment to the wall bracket so I ground it down and then experimented with larger washers.

I found the No.2 washer did work quite well and provided better resistance to movement - but I still wasn't 100% happy.

So I eventually welded (poorly) the head of the screw to the washer and ground a slot for a large 10mm slotted drive that will fit a 1/2 inch socket wrench.

Then liberally applying Locktite to the threads and under the washer - I applied significant knuckle-breaking torque with the socket wrench. But not enough to snap the bolt.

Left it to dry for 24 hrs.

It's now positioned - and no movement!

But if it does - I'm gonna rip it off the wall!

Pedanticism at its worst. 😁

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small D.I.Y. projects to do over the holidays?

Hi @Noyade

Thank you very much for posting that impressive repair project. That's one toilet holder that won't be moving any time soon.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small D.I.Y. projects to do over the holidays?

Blimey, @Noyade! That was quite a fix. I'm not sure that I'd describe anything involving welding equipment as a "small" job. I guess it depends on what you're used to. Nice one!

Did you use a multi-tool to grind the slot?

Brad

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small D.I.Y. projects to do over the holidays?

Evening Brad! @BradN

Anything that fit's in my vice is recorded as a small job. 👍

"Did you use a multi-tool to grind the slot?"

I used an angle grinder/cutter with one of those very thin (1mm?) blades to create that slot.

Today's small(?) job was to repair a length of batten that holds the slats for a Queen size bed. It broke at 0200 hrs last night and my head of the mattress hit the floor with a jolt!

When I looked at the damage this morning I was amazed it never happened sooner. Australian made bed from a now defunct store - the screws that hold this piece onto the inside of the frame had less than 5mm of the screw ends penetrating into the wood. You appreciate this is meant to support a lotta weight. That fully exposed screw shows you where they were positioned length wise.

I selected bigger screws...

Better 'penetration length.'

Glued and screwed. I'm expecting a better night's sleep tonight.

I love this glue (I couldn't find that Best Glue thread?).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small D.I.Y. projects to do over the holidays?

Another one.

I call it 'surgical welding.' Complete procedure performed seated.

A sliding bolt that no longer matches the holding clip.

Surgical procedure - laparotomy and expansion with galvanized metal donor graft insertion.

Horizontal incision with spreading...

Insertion of donor metal graft...

Graft metal is held in place with large curved artery forceps which also acts as an earth contact.

Precision welding - well, sorta...very dependent on the aging surgeon's eyesight..

Cleaned/debrided...

Operation deemed a success. Dressing applied...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Small D.I.Y. projects to do over the holidays?

Hi @Noyade

Thank you for sharing that welding project. I'm truly impressed with the way you connected your welding equipment to the door latch, that is excellent outside-the-box thinking.

Eric

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.