- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Pocket-hole joint gluing: Pine panel end grains are sealed with wax

I just realised the pine panels i've cut to size have a wax finish on some of their end grain, and I'd like to strengthen my pocket hole butt joint with glue.

Whats the best prep to either get rid of the wax or is their another around for a pocket hole join up? What I'm thinking of atm is to scape of the wax as best I can and use gorrilla glue on affected ends.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Pocket hole joint glueing, pine panel end grains are sealed with wax

Hi @adelaide123, and welcome to the Bunnings Workshop community. It's great to have you here.

Our resident Bunnings D.I.Y. expert @EricL will be back on the site later today, and I'm sure he'll be able to give you great advice. In the meantime let me also tag experienced woodworkers @JoeAzza and @TedBear to see if they have any thoughts.

To help our members understand your situation, could you please tell us a bit about what you're making? What sort of Pine panels are they? How big are the pieces that you're pocket-hole butt joining? If you're able to post a photo as well that could also help.

Brad

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Pocket hole joint glueing, pine panel end grains are sealed with wax

Hey Brad et al,

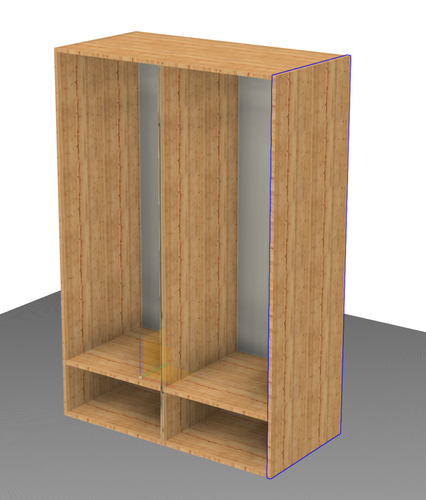

I'm building a wardrobe and the sides are Specrite 1800 x 600mm 18mm Pine FJ Laminated ClearTimber Panels (trimmed to 600, they were about 604). Same panels for the middle, top and bottom shelves. (If the pocket hole joints together with the back 6mm mdf panel prove to be not strong enough I'll reinforce).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Pocket hole joint glueing, pine panel end grains are sealed with wax

Hi @adelaide123. Thanks very much for supplying those extra details and the diagram. I'm sure they'll help Eric and other members in giving you advice.

It looks like it's going to be a terrific wardrobe too!

Brad

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Pocket hole joint glueing, pine panel end grains are sealed with wax

Hello @adelaide123

Thanks for sharing your question about the wax-sealed end of your pine panels. The recommended solvent to melt wax is either acetone or isopropyl alcohol. Please note that if the timber has any sort of finish on it both the acetone and the isopropyl alcohol will strip it off.

Once you've wiped off as much of the wax as you can, please make sure that the panel is totally dry before you apply the timber glue. As for the MDF panel at the back, I suggest using a brad nailer along with some timber glue to keep it in place.

If you need further assistance, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Pocket hole joint glueing, pine panel end grains are sealed with wax

Cheers Eric, will pick up some acetone this arvo. I'll tell them you sent me. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Pocket-hole joint gluing: Pine panel end grains are sealed with wax

Hi @adelaide123 , @EricL suggestions is what I would do, I would also lightly sand both surface after cleaning with solvent, just make sure the area is dry before sanding,

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

| Subject | Author | Posted | |

|---|---|---|---|

| August | |||

| a month ago | |||

| February | |||

| a month ago | |||

| 3 weeks ago |