The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Whole of House

- >

- Re: Laser cut Music Box

Laser cut music box

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Laser cut music box

I used my laser cuter to make a music box Baby Grand Piano. I used 3 ply from Bunnings, which work great and got the movement online.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laser cut Music Box

What a wonderful project, @Super_D! You achieved some excellent results there.

I'm sure plenty of our members would be keen to hear more about your laser cutter, the types of projects you use it for and the process involved. I'd be interested in knowing how long this took to cut, how you glued it together and what stain you've used. I recently got into 3d printing and am super keen to hear more about laser cutting. Any details you could share would be appreciated. Feel free to post some pics of your other recent projects here.

Many thanks for sharing and well done.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laser cut Music Box

Thanks Mitchell,

I always forget to add all the info about the build.

What 3D printing have you been doing?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laser cut music box

A little more info about this build. I used a C02 laser cuter, known as a K40. Its has a 40w tube and is water cooled with air assist from an air pump to help with the cutting and an extractor fan for the smoke. Its only a small laser cuter in bed size and does about an A4 size board, and this just fitted on it. The stain was just a water based stain I had and used for leather work and then just a clear coat. The black keys are just black spray paint and the white keys are just the natural wood colour, but the lines on the white keys is laser cut lines. All just glued together with PVA glue. The music mechanism from EBay for about $5.00... I have seen 3D printed music mechanism, maybe next one. I did have to modify the lid a bit to turn of the music when the lid closed, and start playing when opened. I did this with a little copper post attached to the lid that stoped the music mechanism from turning.

Happy to answer any more questions...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laser cut Music Box

I enjoy crafty-type projects, so I have been enjoying printing objects and painting them @Super_D. I've added an image below of a megalodon tooth, Grant's raptor claw from the movie Jurrasic Park and a raven skull that I'm currently painting. Also, a lot of functional prints like missing/broken pieces. I've done a few items like paper roll holders that I could have likely bought for cheaper than the filament cost.

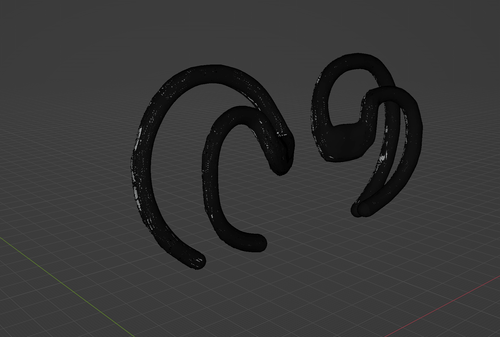

I have also taught myself to use Blender over the last month to start creating organic shapes. I did this as I wanted to design a 3D-printed ear appliance to assist doctors in correcting ear deformities in babies. Apart from plastic surgery, there is a small period where the cartilage in a baby's ear is soft enough to re-shape it before it hardens and takes permanent shape. Many ear deformities can be effectively treated during this period. There's one plastic surgeon in Australia that performs this treatment for free, and I was lucky enough to be able to take my son to him for his Stahl's ear. It is a condition that resembles pixie ears. It's nothing particularly worrying, but it's nice to try and take some of the pointiness out of them. This doctor sees hundreds of patients each year and keeps costs to a minimum. We didn't pay a cent. He and his daughter, that is also a plastic surgeon, spend their evenings bending lengths of wire and forming them into little braces that go in the helix of the ear. The brace is taped in position. We had a lot of difficulty with the tape coming undone during this 3-month process and the brace shifting. I designed these appliances to slip over the ear and provide a better support structure. My hope is that they could also be used to help with more severe deformities. Given the 3D printing filament I've used softens from heat, you can dip the appliance in hot water for five seconds, and it becomes malleable yet is only warm to the touch. You can then place it over the ear and manipulate it to the shape needed. You'll see in the video below the 3D-printed ear buck that I used throughout the design process.

Now that I have the design down and they are printing well, they only cost around five cents each to make. I plan on sending a few dozen to the plastic surgeon to get his feedback. I've only just discovered that a similar 3D printing device was being trialled in New Zealand, and it's had great feedback. Apart from this manipulation of soft cartilage, the only real other option is plastic surgery, which in the case of Stahl's ear, is likely not covered under insurance as it's considered a cosmetic issue and doesn't affect hearing.

Anyway, kind of cool to think of all the amazing things that can be 3d printed.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laser cut music box

This is a beautifully crafted music box @Super_D! I would love to see a video of it playing music when you can.

It is so cool seeing what you and @MitchellMc have created from a laser cutter and 3D printers. I can't wait to see what creative projects you both share with us next.

Katie

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laser cut Music Box

This is super Cool... well done...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laser cut Music Box

You can use a Kinect for Xbox One and a few other free programs to turn it in to a 3D scanner, this was fun to try and a lot cheaper than buying a 3D scanner...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laser cut Music Box

These look Super...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Laser cut Music Box

I just designed and 3D printed bracket to fit a coffee cup holder on an eclectic wheelchair for a friend of my mum in a nursing home.

It is super to be able to help others and make thing that will change their life...

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.