The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Whole of House

- >

- Re: How to strengthening a hollow metal ...

How to strengthen a hollow metal stud internal wall for cat shelves?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to strengthen a hollow metal stud internal wall for cat shelves?

I want to add some shelves to an internal wall in my unit for my cat to bounce around. She's about 5kg. Problem is that wall is pretty cheaply made, with thin metal studs and plasterboard. No insulation. Even the air pressure of opening the door makes the wall move slightly, if I had a slightly fat cat jumping around on it, it would sound like an avalanche, and no chance any shelves would handle that kind of dynamic load as the studs are so thin.

Obviously I'm going to have to get in the wall by cutting out bits of the plasterboard. What would be the most effective change? Was thinking wood inside the metal studs that can be used for better screws, and some form of insulation to dampen vibrations. Any other suggestions other than completely rebuild the wall?

Solved! See most helpful response

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to strengthening a hollow metal stud internal wall for cat shelves?

Hi @minklet,

A hollow metal stud wall should provide nearly the same structural integrity as a timber stud wall. Our suppliers of metal studs have no issues with objects being hung off them, so I'm a little concerned about why your wall is so flimsy.

Given your description, I think you would find it hard to shore up the wall with timberwork, as you'll only really be able to fix it onto the existing steel studs. Obviously, pulling a large portion of the plasterboard off would give you more access and the ability to include a sufficient amount of timber frame and achieve the rigidity needed for your project.

What about creating a standalone timber frame in front of the wall to house your shelves? You could use this project on How to build a cat tower as inspiration and make it larger to suit your needs.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to strengthening a hollow metal stud internal wall for cat shelves?

I'm sure it's sturdy enough in the sense it won't come down, and it would be fine for dead load, but I'm a little sceptical such a thin steel stud can provide the same integrity, and silence, as wood for a dynamic load like a jumping cat - which I would imagine would be more in the region of 20-30 kg. Without using toggle bolts, which I'm not entirely keen on either considering the size of the hole required. Correct me if I'm wrong, but for steel studs you need a very thin thread screw for it to be able to grip the thin sheet metal, so imo any kind of wiggling will enlarge the hole and it will come loose. Pretty sure these are the type of studs in my building, they are pretty flimsy but I believe allow for adding wood studs inside them https://www.siniat.com.au/en-au/products--systems/products/metal-profiles/studs/stud/

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to strengthening a hollow metal stud internal wall for cat shelves?

That's what I've been advised @minklet —either the spring toggles or self-tapping screws.

Adding the timber work would certainly be a more secure mounting point. It all depends on how well you can fix it to the metal studs.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to strengthening a hollow metal stud internal wall for cat shelves?

Adding timber inside the channel of the steel stud is a good option here because it does a better job of transferring the load along the length of the timber than a steel stud does.

Like in this image, when a steel stud fails, they tend to twist and lose the “C” shape which is what gives them their strength.

Adding timber inside the channel of a steel stud can help to prevent the twisting that can cause failure.

Bracing one steel stud to another can also help with this. This is often done in commercial applications to allow mounting of things like tvs and monitors.

See the below image as an example.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to strengthening a hollow metal stud internal wall for cat shelves?

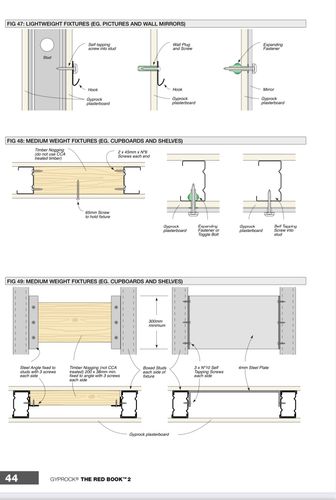

The Gyprock Redbook is a good reference for steel stud construction.

Page 44 looks to be the best thing to look at for your situation.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to strengthening a hollow metal stud internal wall for cat shelves?

Brilliant! Thanks for that @JacobZ95 !

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.