The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Whole of House

- >

- Hevea Timber fibers go prickly when varn...

Hevea Timber fibers go prickly when varnished or wet

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Hevea Timber fibers go prickly when varnished or wet

I used Hevea timber panels from Bunnings to make my desk top bigger (to work from home). I like the blond colour and fine grain however after sanding it smooth, when I varnished first coat it dried rough and prickly as the timber fibers seem to swell and stick up. Gave it a light sand and second coat and the fibers were prickly again. Sand and coat 3 was better but I can still feel it is not as smooth as when I first sanded before varnishing. I noticed an offcut got a bit of water on it and when that dried the surface was prickly too. Any thoughts on this and how to reduce it? Is there a sealer I should use first?

No photos as it is not something you can see but you sure can feel it.

Thanks,

Stuart.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Hevea Timber fibers go prickly when varnished or wet.

Sanding sealer is the product to use. Sand then seal then light sand before applying the varnish.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Hevea Timber fibers go prickly when varnished or wet.

Thanks @Brad I kinda thought there was a product for this. Too late now but I'll know for next time.

Cheers,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Hevea Timber fibers go prickly when varnished or wet.

Hey,

I did the same thing, but on 10 Acacia boards. I asked the Bunnings worker, what should I use and he gave me Cabot’s clear water based. I have done a light sand and cleaned the boards and applied the varnish and it’s dried rough. Will you be using your board even though it’s rough ? I am not sure if, I should re apply and just use them. I am using them in the linen cupboard.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Hevea Timber fibers go prickly when varnished or wet.

Welcome to the Bunnings Workshop community @Mrs_Wortho32. It's fantastic to have you join us, and many thanks for your question.

Did you use a brush or roller to apply the Cabot's product?

I'd encourage you to sand back the roughness with Flexovit 100mm x 1m 400 Grit Wet And Dry and apply another coat with a good quality brush. Using a roller with this product can pick it up into peaks, causing roughness. I've used a foam brush to reduce the number of brush marks, and it has worked quite well.

You might also like to post an image for us if the roughness is visible.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Hevea Timber fibers go prickly when varnished or wet.

Hey Mate,

thank you so much for you’re reply. I used a foam roller only because, I had so many to do.

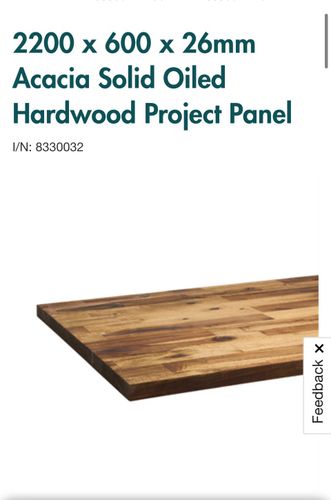

I also did them in the morning before it started to get hot. When I had finished it was hot. I am really confused, the product says it’s oiled and to ready to use, but on Bunnings website the installation guide and product brochure say 2 different things. when I questioned this, the guy at Bunnings said to put a clear coat over it. I explained they are being used for my linen cupboard and won’t be getting wet and he said it’s ok, They still need a coat. I purchased these boards. What are you’re thoughts on this ?

I will post a picture when I get home.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Hevea Timber fibers go prickly when varnished or wet.

The project panel can be used for many different applications @Mrs_Wortho32.

It does come pre-oiled, and this coating would be suitable for projects like desks. The installation guide seems to be concentrating on kitchen benchtops, where a thorough application of oil needs to be applied to both the surface and any cut ends. As far as I can tell, the installation guide is advising additional coats of oil are required for benchtops.

Since this is a linen cupboard and the panel comes with a hard wax oil on it, I'd say applying a water-based clear coat was a reasonable choice. It will prevent any potential discolouration of white linen which would sit on their coating.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Hevea Timber fibers go prickly when varnished or wet.

I think if you clear coat over wax/oil you will get adhesion problems unless you remove the old coating with metho or perhaps better with a wax and polish remover. Basic test if water beads then there is still a coating and if the timber darkens you know the coating has been removed as the water can soak in.

Just for information in South Australia it is a 48 month part time study to learn furniture finishing, the same time it takes to learn cabinet making or furniture making.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Hevea Timber fibers go prickly when varnished or wet

Hi all. I know this is an old feed but thought I send some advice. If a board is just sent through a planer it will not get raised grain when varnished or just very very little . The block glued multi used boards are sent through a speed sander and will have compressed grain from this process and the first moisture, varnish or sealer etc will make the pores in the wood to expand hence prickly surface. The best rule before any costing on timber surfaces that you want to be smooth is to sand them lightly then wipe them with a damp cloth and let dry. This will raise any compressed grain. Sand lightly afterwards and then you can apply your prefered costing. Water based or solvent based. If you are fuzzy you can repeat the water stroking with the cloth twice with sanding inbetween. Happy crafting

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Hevea Timber fibers go prickly when varnished or wet

Hi @hawkan,

Please accept a warm welcome to the Bunnings Workshop community, it is fantastic to have you with us.

Thank you for sharing your experience and advice on this topic, I'm sure our readers will benefit greatly from them.

Jacob

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.