The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- How to notch fence rails around a curved...

How to notch fence rails around a curved corner?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to notch fence rails around a curved corner?

Hi there,

I want to update a fence by removing some aluminium panels and replacing them with rails and pickets. The existing posts are in good condition, so I'm planning on reusing those - however there's one challenge I'm struggling to wrap my head around.

I live on a corner block and the fencing wraps around a corner in a bevelled/gradual way (pics below for reference). I've watched a range of online tutorials videos and understand that I should notch the posts for the rails to sit in. However, I'm struggling to work out the best way to do this for the sections that curve around the corner. I have found one video that did something similar - however, they opted to cut the rails to match the distance/angles of the inside of the posts and then simply screwed them into the side. I imagine this is not as strong or durable?

Any thoughts on best way to approach?

Thanks heaps

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Notching fence rails around a corner / curve

Hello @jt-trestles (Jacob)

Welcome to the Bunnings Workshop community. It's sensational to have you join us and thanks for sharing your question about your fence rails.

Notching your timber post and inserting the rail into it means that whatever load is placed on the rails it will be transferred to the post because of the notch. If the rail is screwed on directly to the post this means that all the fence weight will be held together by two screws on the post.

I suggest offsetting the position of the rail when you get to the curve. One rail will be at the top the next rail will be at the bottom of the first top rail. In this manner the rail will get a solid grip on the post and will have a full seat on the notch rather than sharing it with the other rail.

Let me call on our experienced members @woodalwaysworks, @diy_hausdesigns and @WoodenGregsWood for their recommendations.

If you have any other questions we can help with, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Notching fence rails around a corner / curve

Thanks EricL,

I ended up going for a slightly different option to your recommendation (I used single notches) and thought I'd provide an update here in case it helps anyone else googling this in the future.

For the corner sections I cut my notches slightly shallower (approx 32mm depth instead of 38mm) and then chiseled in towards the centre of the post manually to the full rail depth. This provided a slightly cleaner finish as the rails ran (mostly) flush into the post and didn't leave big gaps where the notch was deeper, or overhang on the back of the panel.

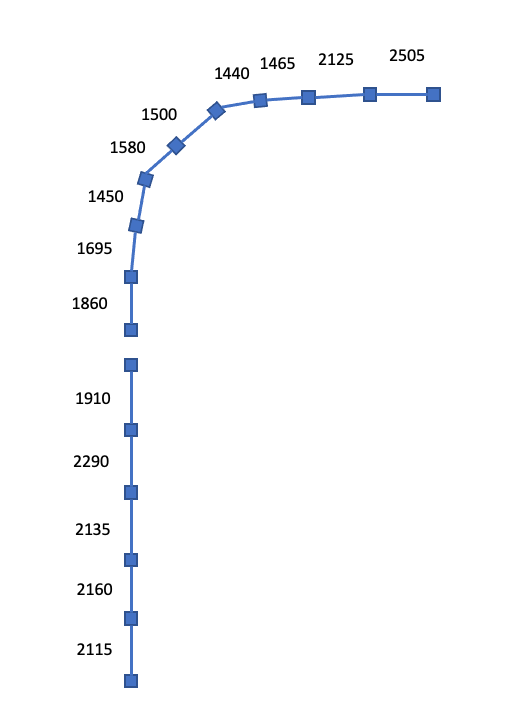

I also had some pretty random angles around the corners so I used a digital protractor to work out mitre angles so that the ends of the rails sat flush in the post notch. I found this video quite helpful for wrapping my head around how to do this.

Here's some pictures of the finished product - definitely not perfect, but good enough for my purposes.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Notching fence rails around a corner / curve

Hi @jt-trestles,

You've done a fantastic job here; you should be proud of the standard you've produced.

Calculating angles for abnormal mitres can be extremely frustrating, so to achieve the result you have is brilliant.

Thank you for getting back to us with your finished project and for sharing how you got it over the finish line. It is always great to see and learn from each other's experiences and to see the methods that were used.

If you have any future projects, please keep us in mind, it would be fantastic to see what else you come up with.

Jacob

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.