The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Ground level low-profile deck

Ground level low-profile deck

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Ground level low-profile deck

Hi everyone,

I want to build a deck of around 14m x 1.3m on one of the sides of my house.

I checked many forums, websites and post here and there. I learned a lot but I still have a lot of doubts. Most of the information out there is about huge decks built in which I guess are cyclonic areas or with extreme weather conditions like snow, etc. I live in NSW and I think a ground-level deck could be somehow much and simpler, with fewer components while remaining robust and compliant with the local standards.

As you can see in the pictures below, the area is next to the neighbor lot. Also, I need to dig out some centimeters (maybe around 20'ish cm) in order to make the deck flush with the terrace and side entrance. Currently, there are 4cm between the terrace level and the soil.

- Do I need to leave a gap between the colorbond fence and the deck?

From my understanding, the classic deck structure has concrete pads, some sort of galvanised stirrup like this, posts, beams, joists and the decking board. In order to make it flush with the terrace, If I use all the above, I will need to remove a lot of dirt .

For instance, I was thinking of using like a 300mx300m concrete pad, galvanised stirrup on top of it and then beams and joists at the same level like the following (sorry for my draft 2d/3d sketch).

What would be the minimum required components for a low-profile deck? Which brackets are appropriate for a low-profile deck without posts?

Providing that I need to remove some dirt next to the fence sleepers (see img below) they used to level up the fence:

- I wonder if it could somehow collapse. What can I do to prevent that?

Last but not least, can someone (@MitchellMc ? ![]() ) help me to calculate the beams/joist and concrete pad needed based on the above deck dimensions?

) help me to calculate the beams/joist and concrete pad needed based on the above deck dimensions?

Cheers,

Tavo

Community manager's note: Check out How to build a low-level deck for expert advice.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Ground level low-profile deck

Hi @tavo1421,

90 x 45 outdoor framing timber would be suitable for the ledger, and I'd suggest placing Ramset 12 x 125mm Galvanised DynaBolts every 600-800mm along its length. Once you've placed your Dynabolts through the timber, you can place a stack of five galvanised washers onto the bolts before inserting them into the wall. I'll illustrate this below, and the washers are in red. This gap stops moisture from being caught between the ledger and tiles and prevents premature decay.

Dynabolts get inserted into a hole, and the action of turning the nut expands them.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Ground level low-profile deck

Amazing thanks for the explanation.

I wonder if, on the other side of the deck, where there is not a brick wall but a colorbond fence, I could extend the joists as I explained before? Is there another better way to get closer to the fence?

Thanks again.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Ground level low-profile deck

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Ground level low-profile deck

Thanks again.

Sorry but as I move forward with the design I have new doubts.

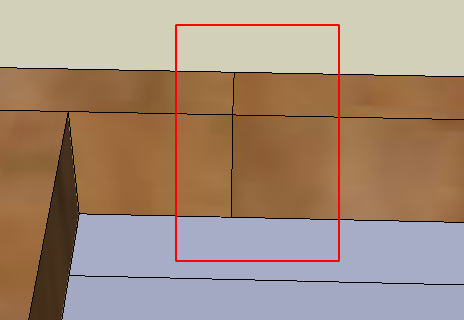

In the side closer to the colorbond, in the joint between two bearers like here:

Which sort of connector should I use? A connector plate like this, Knuckle Nailplate like this or what you recommend?

For the joint bridges like the ones below, should I use a 90 degree connector with nails? Can I use some type of timber screw from the other side? both? which plates and/or screws do you recommend?

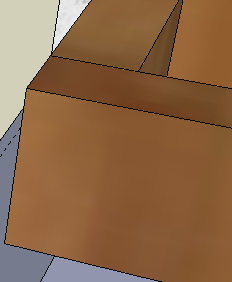

Same for the corners like the one below. Should I use a 90 degree connector and nails from inside? Can I use some type of timber screw from external side? both? which plates and/or screws do you recommend?

Cheers,

Tavo

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Ground level low-profile deck

Either of those two connector plates would be sufficient @tavo1421. Personally, I'd recommend going with the Pryda Nail-On Connector Plate 75 x 125mm so you can drive some decent length nails into the timber.

For the joint bridges, Pryda Joist Hangers Suits 45 x 90mm would be the best choice. Alternatively, you could screw through the timber into their ends.

At the corners, I'd recommend screwing through them with two Zenith 14G x 85mm Galvanised Type 17 Batten Bugle Head Timber Screws. Alternatively, you could use a Pryda Multigrip 100 x 35mm on the inside and outside of the joint.

I hope that answers your questions. Please let me know if there is anything else.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Ground level low-profile deck

How is your deck project going @tavo1421?

It would be fantastic to get an update as your project has been very popular with the community.

Many thanks,

Jason

- « Previous

- Next »

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.