The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Courtyard privacy fence and gate build, ...

Courtyard privacy fence and gate build, Part 2

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Courtyard privacy fence and gate build, Part 2

This is the second part of the project for a privacy screen. I wanted a higher screening then the old side gate as my neighbours across the street could see my pool deck from their patio.

When I designed it originally I was going to keep bees up top behind the handrail as it would stop wind and allow access easily. Since then I have realised that it gets no sun in winter. The bee hives would either collapse or the bees would bail. However I still wanted the privacy so went through with the build. The platform will be used for something at a later date. And yes I have a few ideas ![]()

I hate the idea of hanging a gate off a fence. It will make it lean no matter what you do, and as can be seen the fence has a lean to it now. This whole screen/future gate is freestanding.

Materials

Macsim clever tool (Countersink drillbit)

Macsim 8G * 51mm Square drive Chipboard screws.

Soap

Reclaimed Timber from Various sources.

Tools

Ozito Drill and Impact driver kit

Makita Hammer drill Level

Level

Ratchet straps (Best unspoken tool ever!)

Drill bits various

Chisel

Mallet

Steps

Step 1

The main part of the frame work had been completed in the first stage. (Courtyard privacy fence and gate build) This is the fleshing it out stage. I almost changed the design as I could see how large/tall it was going to be. I decided to keep it the way it was originally designed as the courtyard gets a serious amount of sun in summer and this would help cool the area.

This is for the middle rear post that the handrail would attach to. I ended up putting a second crossbeam up as it did not look strong enough with just one cross beam.

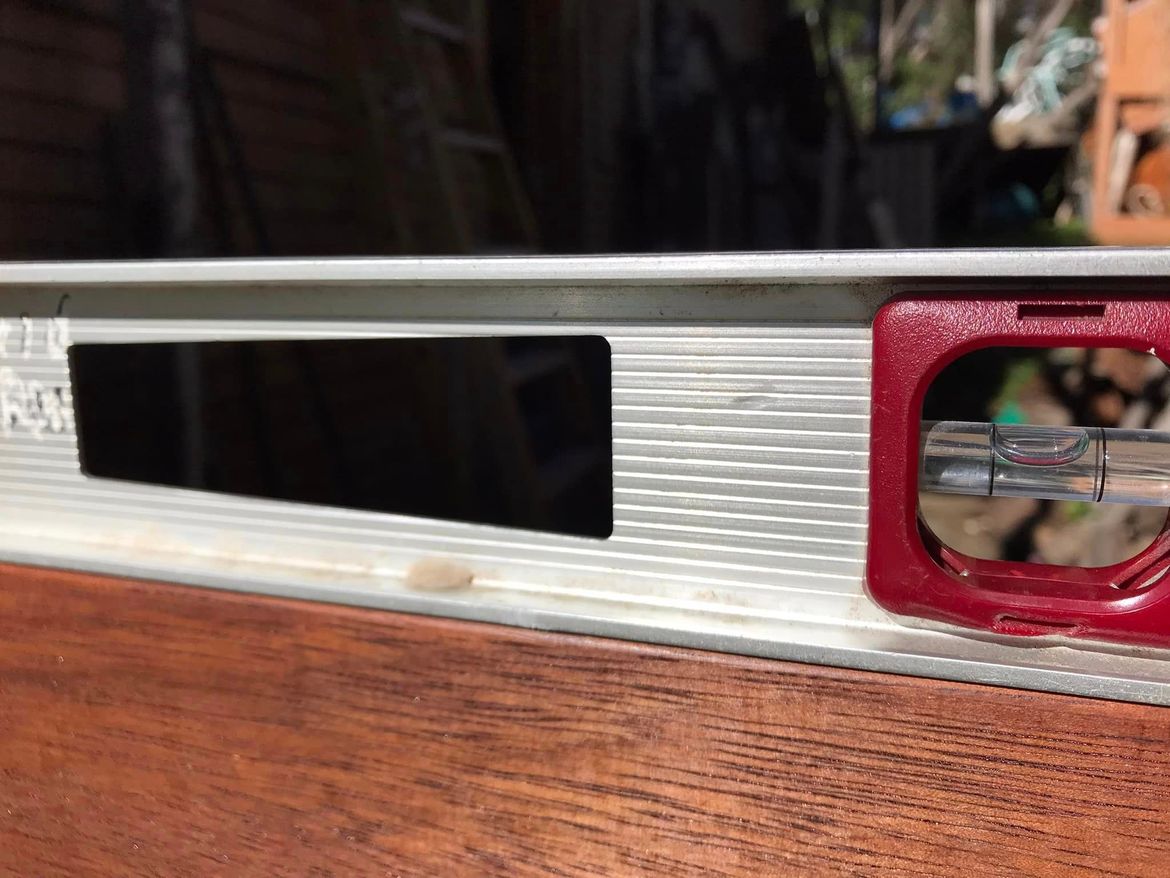

Reusing old timber that has twists and curves in it can be interesting.... You can see how far out of true it was,

All the posts are in and you can see the temporary slat to hold the middle post in its position. It actually set into position as I tightened all the bolts up/plus time.

There is a 19mm slat screwed vertically to the middle post as the post was 15mm out of true at the base (I dont know how I managed that!)

Made up short bits for the floor beams to bolt to. I didnt want any vertical screws for water to just sit in.

Reusing timber can be a pain but I think its worth it as it adds character.

Step 2

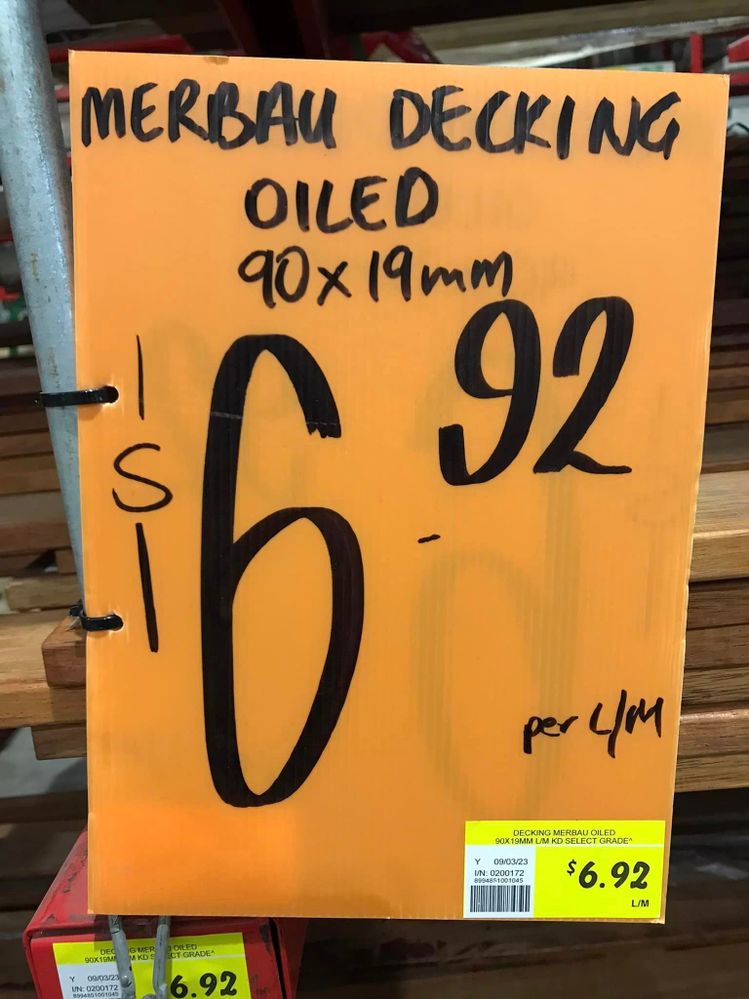

Finally get to start putting the slats up. The bottom two are wider pieces as I managed to get them on special and also I knew I was going to have issues with the stirrups of the posts. (Looking at it I should have turned them 90 deg when I was installing them originally). Live and learn I tell myself.

Old gates have been removed plus their brackets that held them to the wall and the fence. They were NOT coming off easily.

Getting the first slat in place and level. Because I had messed up with the stirrups and bolt heads poking out I cheated by recessing the timber slat to match the head of the bolts (To do this I belted the timber held against the bolt head with a mallet to indent the wood so I could drill it out)

Level ![]() If the first one is level then the rest should be a little easier.

If the first one is level then the rest should be a little easier.

Recessed holes for the bolts to sit in. It worked a dream. Having to drill the pilot hole through the timber and stirrup to be able to use the screws was a pain tho.

Ran into an issue. I had last used these almost a decade ago and when I was using them this time I was shearing them off. I was using them into the same type of timber slats and hardwood frame. For the life of me I couldnt figure out what I was doing wrong..

Sheared off four screws in two pieces of timber... What the!

Bingo... Call me a dolt. The original deck I built I used a torqued drill for the screws. (Impact drivers were not around easily to buy a decade ago) This time I was using an impact driver (I dont know why) and the screws were just snapping. I talked to Bunnings staff and the two staff I asked had some suggestions. (Use stainless screws as I was using the wrong screws or use soap on the screws with the predrilled holes.)

The drill I used for counter-sinking and pre-drilling of the holes. (Same tool I used for the original decking)

Once I had woken up that I was using the wrong drill (I was using an impact driver instead of a torqued drill) life became way easier and didnt shear any more screws at all.

The Bunnings staff member suggested I use soap on the screws. It worked a dream!

Level! ![]()

Step 3

I came up with a complicated way of levering the slats down to be level (Had a few lengths that had a banana shape to them.) Then I thought about the ratchet straps and figured why not give it a go. Sped up the job by 4 times I would say.

The way I was levering the slats down before clamping and drilling them. It was complicated and would slip like crazy.

Time to call it a day. Feeling happy with the way its going.

One thing I found is that the end of the slats were not always square.

At the point of needing to put the deck part down so I could continue with the slats.

Started using my brains. I Used the ratchet straps looped around a lower fixed slat and tighten. Made sure the banana bend was high on one side (Not high in the middle). It was a lot easier doing it this way. The spacer was an offcut piece of 8mm timber

Putting the decking down. Was a little bit of working as to how I would run them with the posts being out. I ended up following the straight line of the front timber slats.

Worked it out and then used some large rivets as spacers.

Used a pair of long nosed pliers and a screwdriver as a flat bar to lever out the rivets. I didnt want to mark the timber with the long nose pliers.

Before the ratchet was tightened.

Sometimes the warp was largish.... Ratchets made it work.

Notching out the floorboards for the deck. Trying to think if I had put the notches on the right side.

Yep, managed to put them on the right side! And more ratchet work needed.

End of the day and I heard a "crack" as I stepped over some tools... I had snapped the drill bit. Off to Bunnings again! I stopped work as I wasnt paying enough attention and was making small mistakes.

Deck is done!

Happy with it. I have left the joists hanging out as may attach something to them later (As in a sail or string of lighting)

Always helps to take a photo of what timber you buy before going to pay for it at the trade desk ![]()

Step 4

Handrail time, Trying to figure out the height I wanted and make sure it would be legal. Also I really didnt want to cut the post height (was just being nervous as once cut it was cut) Finally just bit the bullet and did it.

You can see the ratchet strap I was using on the left.

It was nice getting an edge to the decking part.

Taking shape and realised how tall it actually was.

Posts have been cut, the slats at the front are at the right height. Next stop the handrail. I asked the Workshop community for some suggestions (Workshop question) and actually used one of the suggestions (My idea would have been way to wide with a fierce overhang)

First time ripping a piece of timber. It went well. I Was just nervous doing it.

Making up the edge of the handrail. I made a long "L" edge to stop the flat flexing so much and to allow me to screw the back of it to the posts instead of down into the post (That would allow water to get in and rot)

Notched the right hand end to match the side slats of the deck. I predrilled the holes as I almost split the timber as I was drilling into only 19mm width.

The flat timber on top is 140mm wide and only has screws into the 35mm timber across the back of it. I screwed The 35mm piece to the posts. There is no flex in the top plate and no way water can sit and pool on the top of the posts.

Pretty happy with how it came together.

This is why I had notched the underneath slat. I knew that it would come up against the side slats of the deck area and wanted it to fit nicely.

All done. The sun was going down otherwise the timber shines! One day I will fit the gate to the fence. But as is it is very secure. I will oil it in a week or so when no rain is expected.

I may put some slats between the deck and the top of the fence (ran out of material and money) But will see. This is taken from my neighbours driveway.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Courtyard privacy fence and gate build, Part 2

Hi @Dave-1

Thanks for sharing that update, I was curious to see how the panels would go on once the frame was in place. It looks fantastic and would make a great spot for morning tea or coffee.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Courtyard privacy fence and gate build, Part 2

Thank you! Tho it may be a little hard to get to for morning tea lol It would be a very nice spot tho. The two ideas I have for it are.

A steep staircase that can be taken off as needed (think a ladder with deep steps)

Or and this soudns a little out of the way. But a narrow walkway for a doggo. When I have had a dog in the past they would run from side gate to side gate. and I thought how good would it be if you were a dog and ypu can stand on teh fort and look out at all your lands ![]() (The viewing portal would be a front load washing machine plastic piece reveresed. )

(The viewing portal would be a front load washing machine plastic piece reveresed. )

Need to lay hands on some resources but they are the two ideas I have for it ![]()

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Courtyard privacy fence and gate build, Part 2

Afternoon All

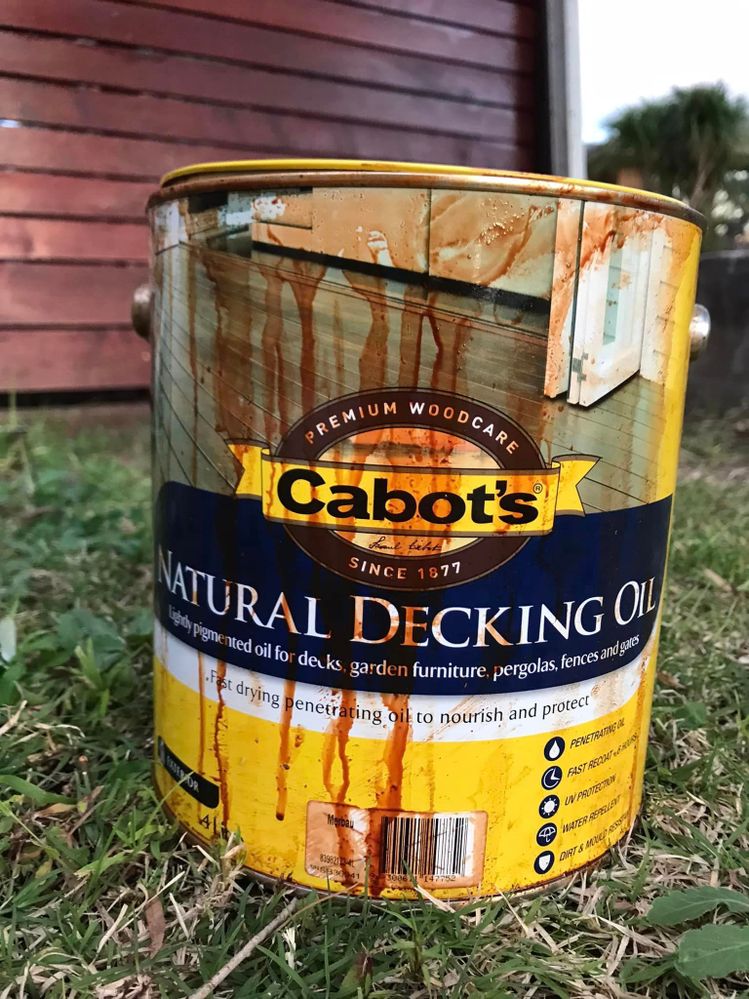

Here are some pics of the Privacy screen after I have given it one coat of oil.

The bare patch is to show the difference between the non oiled and oiled part. Only 5ish weeks since I finished the wall and prob 9ish weeks from start of putting the boards up. Amazing what the sun will do.

Even tho the recycled timber was dry I still decided to oil it. It drank the oil like there was no tomorrow!

Glad I did the underside.

All done and as I was packing the tools away there were spits of rain! The oil had pretty much soaked in but still I was worried. It also rained last night but couldnt see any runoff on the cobcrete this morning. Will have a better look this afernoon when I get home.

Just so I dont loose what oil I used. I had just enough oil for one coat! ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Courtyard privacy fence and gate build, Part 2

Hello @Dave-1

Thank you very much for that update, that Merbau decking oil stain looks great and gives those panels such a beautiful finish. I'm looking forward to the installation of the steps and a good picture of the view from above.

Eric

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.