The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Living and Bedroom

- >

- Re: how to fill the holes and gouge

How to fill the holes and gouge in my door?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to fill the holes and gouge in my door?

Hi, mates.Good morning!

The handle of my bedroom (image1) is out of work. I removed the old handle and now there are two holes in the door( image2)

Second problem ,the flush pull of new handle is 7mm length,but the old is 12mm, much bigger than new one. (Image3)The old handle also left a gouge in the door.( image 4)I need your guild to fill these holes and gouge before I install a new handle.The thickness of the door is 40mm. Thank you so much!

vica

Solved! See most helpful response

- Labels:

-

Doors and Windows

-

Repairing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: how to fill the holes and gouge

I'm so pleased that worked out for you @newfast. I couldn't bear to see your project halted at this stage after you've put in so much effort.

Keep up the great work!

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: how to fill the holes and gouge

its called the internet, and the marvels of cyber space then it could be the demands on Bunnings servers.

when you start mounting the parts in place, take the door off and lay it flat, the best way to do this is remove the hinge pins that way it is much easer to put the door back up and no screws to try and put back in

I can not stress any stronger use cardboard to make the template for the replacement section that way you can cut the shape need with out wasting timber

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: how to fill the holes and gouge

Hi Folks, I did some basic prep after work, the masomite is kind of slim n light so the wooden packers be best to go behind it.

Removed the main honey comb, vaccumed and gave another round of cleaning edges.

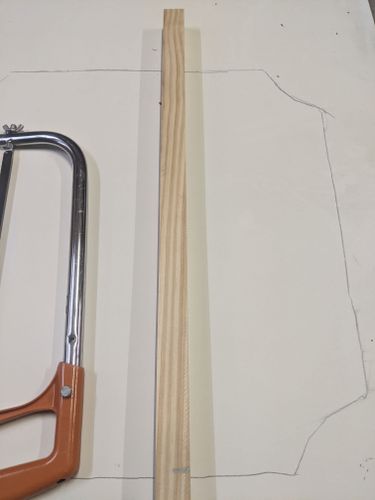

The wooden packer appears to be too big but I managed to insert it and mark it to cut

@r23on I am not sure if removing door be a right steo with my skills ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: how to fill the holes and gouge

It’s just a matter of knocking the pine out of the hinge in doth cases a 75mm nail tapping up ward will remove the pins .

secondly this is why is said to make the packers 50mm longer and to use the masonite as the packers even if the packers were 60mm longer it’s would not matter

slip the packets in 25rmm each side or 30mm each side. the thicket the packer the harder it is to get them in. the other approach is to come in at an angle top to bottom twisting up wards. in other words bring the packer is almost vertical then rotate the packer to the horizontal. to top it off the g clamps will not fit with that material.no where for the clamp to fit

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: how to fill the holes and gouge

Just to add another alternative for packers... to make it easier, given what you have, you could just use strips of Masonite as packers, now that you have plenty. The purpose is just to keep the inserted panel straight, not carry any load. This is what those thin strips of honeycomb were doing before. Suggestion:

Cut 3 strips, the width of the gap inside the door, (between the front panel and back. ie the width that you would have trimmed the timber packers down to). Make the lengths about 40mm longer than the hole, so 20mm can slide up inside each end of the hole.

Put glue down one edge of these strips and 20mm of each other edge's ends and slip in the gap vertically (they will slide down if horizontal), with glued edge at back.

Put 1 strip in centre & other 2 between that and the edges. Now you have 3 stiffeners.

Now cut 2 more strips 50mm wide and glue them in flat (not on edge) halfway into the vertical edges, so they protrude 25mm to form the side supports as shown in @r23on's earlier drawing. Clamp those in until glue dries. It would be wise to also cut some shorter 50mm strips to fill in edge gaps along top and bottom edges, (but not as essential, since vertical packers will align those edges).

Now you will ready to replace the panel.

(Make sure that you make the new panel to fit before you pack the hole, so you can slide the cardboard template in and out. Cut a finger hole in the middle of that template so you can handle it easily.)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: how to fill the holes and gouge

@TedBear damn....that is some serious mind bogling thinking

I will cut the 3 one size and 2 other size strips tomorrow.

1 question ,m:- the masonute seems flimsy when I be cutting whats the best way...put it on 2 shairs or make it stand and hold it in angle while I cut with the saw

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: how to fill the holes and gouge

Hello @newfast

It's great that you've received fantastic advice from @TedBear. I suggest cutting the masonite panel on a flat surface or table to prevent it from oscillating while being cut. You can either get some clamps or have another person hold the panel to prevent it from lifting while you are cutting it.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: how to fill the holes and gouge

The method I use for cutting masonite is often "score & snap", because it is, as you said, thin & flimsy. But you then need to file the edge square since it doesn't always snap off cleanly. A better method for you would be to lay it flat, score the surface with a knife, shallow first to get the line straight, then cut a bit deeper, then put it between chairs (cut-line is close to one of them), then use that groove to guide you as you saw through the board. Use the saw at an almost level angle, so that as many teeth as possible are sliding along the cut. If you saw too vertically the teeth will grab on the thin board and break through, rather than slide through neatly. That's easier and gives a better, smoother cut.

(Of you want to try the Score & Snap method, make sure you score the back too. I'd only use that for the two strips for the edges of the hole, because their width isn't critical, so messy edges won't matter.)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: how to fill the holes and gouge

Not happy with myself....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: how to fill the holes and gouge

Oops; What happened?

Hopefully having extra Masonite means it's an inconvenience, not a disaster.

(I have often described some of my projects as a series of repairs joined together. Welcome to the learning curve of D-I-Y.)

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.