- Bunnings Workshop

- >

- Discussion

- >

- Living and Bedroom

- >

- Re: Can vertical Specrite Panels handle ...

Can vertical Specrite Panels handle the weight of a Murphy Bed?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Can vertical Specrite Panels handle the weight of a Murphy Bed?

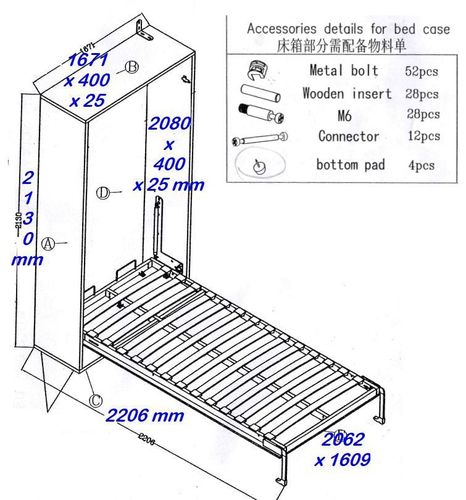

My wife has bought a full Murphy bed kit, all except for the timber bits. Attached is the overall look of the bed from their Instruction booklet.

That leaves me with 2 Questions.

1. As the Specrite panel is a laminated board, will it have sufficient strength to handle the mounts for the frame?

Hint: the usual occupants and dog will add up to about 250 - 300 kg.

My thoughts were to use the SpecRite 2200 x 600 x 26mm Multi-Use Merbau Panel as the best option to hold tight the mounting screws. The backplane and under-bed panels will probably be BC (as the facing panels need to be furniture grade) or CD 17mm ply.

2. The bed frame manufacturers suggest keeping it all together with the fittings shown in the top right of the image. In other words, the kind of light to medium-weight cupboard fixings that you could expect to find in any kitchen, or cupboard flatpack. I have successfully used these many times in the past on kitchen cupboards, shelving, and other furniture but I think the Connector Cam sets are not adequate for fixing these heavy sides to the back plate and transferring all of that strain and stress.

I have bought some packs of the Connector Cam bolts but I am open to suggestions on better ways to fix the backplane to the surrounds and butt join the two pieces of 17mm ply needed to make up the backplane and the pieces under the mattress. They suggested double-ended Cam Connectors but couldn't find any at my Parafield SA store so I also bought some of the Hafele Benchtop connectors only to find they stand too high (22mm high) and will have to go back.

What is left for me to try?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Can vertical Specrite Panels handle the weight of a Murphy Bed?

Hello @ilox

Welcome to the Bunnings Workshop community. It's sensational to have you join us, and thanks for sharing your question about your Murphy bed.

As much as I would like to say yes to the SpecRite 2200 x 600 x 26mm Multi-Use Merbau Panel. I'm afraid it will have to be a no due to the way it's constructed, it might at some point split part as it is technically timber pieces that have been glued together. It's great for bench top use, but as soon as you start using it for something else it would be difficult to tell.

You are better off using the 17mm ply. If you need a thicker piece, it's possible to glue two sheets together and keep them together with screws. In regards to the corner fittings, I propose using Specrite 70 x 35mm 0.9m Short Pine Run Of Mill In the corners. This will help with the structural stability of the frame. Plus, it is more reliable than the Connector Cam Bolts.

If you have any other questions we can help with, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Can vertical Specrite Panels handle the weight of a Murphy Bed?

Thank you for your very helpful reply, Eric. Agree about the possibility of the Specrite Laminated board splitting so I was thinking of going to a solid wood such as 240 x 45 or similar. The framing gear that supports the bed needs a minimum of 240 mm wide so that would be what I was looking for. I had not considered doubling up 17 mm ply but sure, not a bad alternative. If I took this into 400 mm strips that would double to ~34 mm which would give me the secure stable support I am looking for. Unfortunately, I can't find any BC-grade ply in my local Bunnings store, only this CD-grade ply. Maybe Special Orders could get it in for me? I want the outer face at least to be furniture grade.

The other question was about the use of those Cam Connectors. As I said in my first post, I just can't see that they will be a good strong connection for the side fixings and the butt joint of the back and bed panels (17mm BC or CD ply). I was thinking of fixing them with alternate direction Pocket Screws with a decent Gorilla Glue to get the edges level and hold them that way. Do you think that would give me the best outcome?

I like the suggestion of a short piece of wood to hold the screws, I have used that many times before so am very familiar with working that way. I trust that method far more than I would trust the Cam gear. I would normally use ~20 x ~20 but with the inner edge slightly rounded to help it sit into the corner better.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Can vertical Specrite Panels handle the weight of a Murphy Bed?

Hi @ilox,

I'd recommend chatting with the Special Orders team at your local Bunnings stores, as they'll have access to the entire range of plywood products from the suppliers in your area. Accessing BC ply should be an issue, they'll just need to check as to whether they can order individual sheets.

I'd recommend going with pocket screws instead of the cam connectors or even just butt joints and filling the screw holes with timber-matched putty. A timber section to reinforce the joint would be a sound choice.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Can vertical Specrite Panels handle the weight of a Murphy Bed?

Thank you for the suggestions. I have purchased some lovely Victorian Ash from a specialist timber provider. Two pieces for each side, 2200 x 290 x 45 and 2200 x 120 x 45. I will butt join them using glue and 1/2" dowels or similar. That will give me a side of 2080 x 410 x 45.

The facing of the boards that are under the bed but make the face of the 'cupboard' (when the bed is upright) will be 15mm Ecoply faced with 3mm BC ply. That should look good.

I will use the scrap 3mm ply to make strip's for the edges of all four facing edges for the framing plus the bed ply pieces..

The top and bottom panels will probably be cut from rhe 2400 x 600 Specrite sheets. Or maybe one of the 2200 x 900 sheets which will give me both top and bottom plates 1711 x 410 x 33 mm..

A former neighbour chippie suggests using the 75mm hex socket bugle long screws to fix the Ash to the top and bottom plates as the heads will not ever be seen.

Along with the back sheets of 17mm ecoply, all of that should be strong enough to keep the frame square and in place regardless of the weight of the usual bed occupants (one is big build, and other is around 180 kg!).

It all will make a quite expensive bed but with the weight it will have to handle I have to over-specify.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Can vertical Specrite Panels handle the weight of a Murphy Bed?

That sounds great, @ilox. We can't wait to see your project come together and the results, so please keep us updated.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Can vertical Specrite Panels handle the weight of a Murphy Bed?

Well, it has been a long haul to get to this stage but on Thursday I took my Cutlist and Bank card to Bunnings Parafield. I came out around $400 less in the bank but all planned on picking the pieces up and hiring the Handy Ute to get them home.

I admit to leaving a box of Easter Eggs to thank all the Trade and Cutting staff who gave their advice and assistance to make all this come together.

Around Lunchtime today, Sunday, I went through the rigmarole of hiring the ute and then loading all my pieces and offcuts onto the Ute's tray.

Since getting them home I have identified each piece, measured and marked them, and brought the actual parts into the spare bedroom to mock up how it might look.

I think this is going to work and I am very excited.

Oh, after a lot of running around town, because Bunnings won't cut down any outsider timber for obvious safety reasons, I got the 45 mm thickness cut back to 25mm. With plans for the 10mm offcuts, I am delighted with the job by Moyle Bendale Mouldings, just across Cheltenham Parade from the Bunnings Woodville store.

So, tonight I mocked up how it might look. It is great to see it come together after these months of planning, pricing and drawing.

The pieces are just sitting together, just to get the feel of how it might look when done.

The gaps in the back panels have me worried. It has all been cut according to the plans but the gaps do seem to be there.

Note that here we see the B side of the 3mm BC plywood that will be the facing skin when the bed is folded up. In later pictures, you will see that we have chosen to use the C side as a better fit for the tone of the bedroom.

This picture shows the C sides of the 3mm ply. My wife and I, and the future bed users, all agree that this will be the better side to use.

These next photos show the frame and mounts jerry-rigged to check the final width of the bed portion - 1625mm. With the 25mm of each side that makes 1675mm width. The plans say 1671 but their mechanism tells a slightly different story. I think that we will make it, just.

The holes are practice runs with my new Ozito Biscuit cutter. Just love using it!

The pieces of the Ash - 290 and 120 mm, have been side-joined using 9 or 10 biscuits along the 2 m length. The system sure helped keep the pieces in line when gluing together (with gorilla glue).

Now to dismantle the frame before heading to bed or maybe not... sleep is calling.

PS. The adjustment holes in one of my 900 mm Craftrite sash clamps don't line up with the pin for the backstop. Might have to take it back or even drill them out a little more.

PPS: I can post more photos later if anybody wants to see how I joined them.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Can vertical Specrite Panels handle the weight of a Murphy Bed?

Great work, @ilox! You had me worried for a second. I saw your last image first and presumed things had gone horribly wrong and the timber had snapped; now I see it was just a mockup.

I trust our members would love to see every step of the process, so keep those updates coming.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Can vertical Specrite Panels handle the weight of a Murphy Bed?

Update:

I was trying to get it done by Easter. Maybe the next milestone should be Anzac Day?

So here is where I am at on Tuesday 2/4/24.

Here I am using the 10mm offcuts of Victorian Ash to fix onto 15mm Ecoply. I have had to use a double row of 20mm screws abd lots of clamps because the offcut has a slight curve where the bandsaw cut the 45mm down to 25 and 10 mm.

These will be the Top and Bottom of the box. So far the Bottom is completed and in place, drilled and just waiting for the sides to be screwed on. Top is the next job.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Can vertical Specrite Panels handle the weight of a Murphy Bed?

I have sanded down the big sides (2080 × 400 × 25mm) using the Ozito detail sander. So much recharging to get both sheets down to at least ax240 grit finish.

I have drilled for the M8 Insert screws/T-nuts and fitted the side plates that will hold the bed frame axis point.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.