The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- How To

- >

- How to waterproof a shed floor

How to waterproof a shed floor

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Beginner

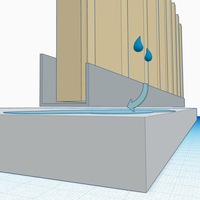

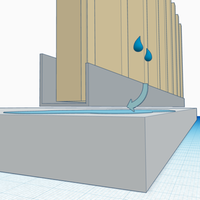

Water seeping under shed walls can cause damage to your stored items and be a potential safety hazard.

Here is a simple guide to waterproofing a shed on a concrete slab using an aluminium angle and sealant.

You can also keep items dry in your shed by installing a new floor. Check out our guide How to install a shed floor for step-by-step instructions.

Let us know if you have any questions.

Steps

Step 1

Clean the concrete slab.

Use a pressure washer to remove any dirt or debris on the concrete slab outside the shed. Make sure the area is dry before proceeding. This will help ensure the aluminium angle adheres properly to the shed wall.

Step 2

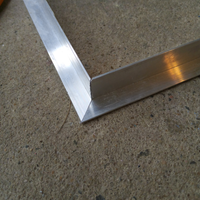

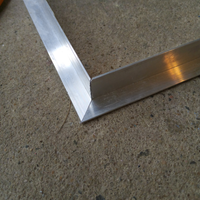

Cut the aluminium angle.

Use a tape measure to measure the length of the shed wall that needs to be covered by the aluminium angle.

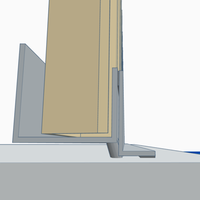

Cut the aluminium angle to size with a hacksaw. It's a good idea to use safety glasses and gloves while cutting. You can use a mitre box to cut the aluminium angle at a 45-degree angle for the shed corners.

Step 3

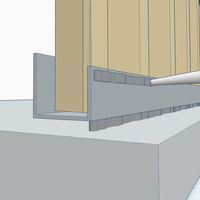

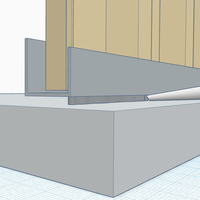

Apply sealer under the shed wall.

Cut the sealer nozzle with a retractable knife and insert it into your caulking gun. Don't forget to wear safety gloves and cut away from your body.

Starting at one end, apply sealer along the bottom of the shed wall where it meets the concrete slab. Apply the sealer evenly and smoothly.

It’s important to apply enough sealer to contact the concrete slab and the underside of the shed wall. This will prevent the water from seeping under the wall and into the shed.

Step 4

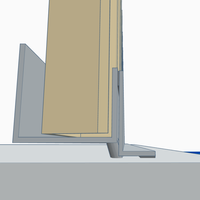

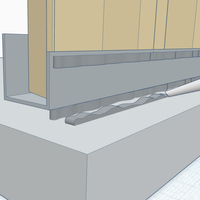

Apply sealer on the shed and concrete slab.

Apply two more sealer beads, one on the vertical face of the shed's bottom trim and one directly in front of it on the concrete slab. This will help ensure the aluminium angle is firmly secured to the shed wall and concrete slab.

Step 5

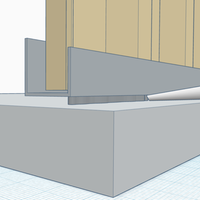

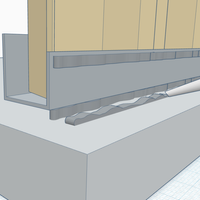

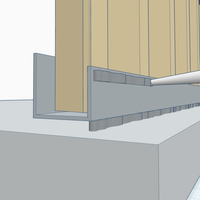

Attach the aluminium angle.

Attach the aluminium angle to cover the gap between the shed wall and concrete slab. Press the angle firmly against the wall and concrete, ensuring it is level and straight.

Repeat Steps 1 to 5 for all four walls of your shed. If a smaller trim piece has been used on the bottom of your shed's door, apply only the sealant to the door's front edge.

You have now successfully sealed your shed.

Materials

- Aluminium angle, like Metal Mate 20 x 12 x 1.4mm 3m Aluminium Unequal Angle - Silver

- Sealant, like Sika 300ml Grey Sikaflex 11FC Plus Polyurethane Adhesive Sealant.

Tools

- Tape measure

- Mitre box

- Caulking gun

- Retractable knife

- Hacksaw

- Pressure washer

- Safety glasses

- Gloves.

Images

You must be a registered Workshop community member to comment. Please join Workshop or sign in to join in the discussion.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.