- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Intermediate

You can create an awesome cubby house for your kids using recycled pallet timber.

This cubby has an additional shop and can be built over a few weekends for a minimal cost. And you can feel great in the knowledge that you’ve created something special for your kids while helping to save the planet by recycling pallets otherwise destined for landfill.

Steps

Step 1

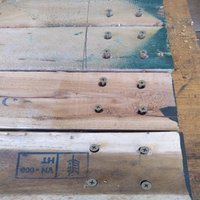

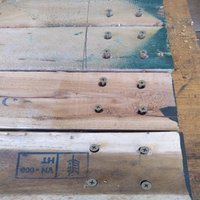

1/16Pallets can be sourced from many different locations. It is best to use unstamped pallets or those with a HT (heat treated) stamp to avoid risk of exposure to chemicals. Many Bunnings locations offer free pallets and they are perfect for this project.

You can use a pinch bar to remove the individual boards from the pallet, but using a cordless reciprocating saw slicing between the boards and beams and cutting the nails is an efficient option. This method stops a lot of wastage from broken boards which will inevitably happen when using a pinch bar. It also means you don’t need to hammer out many nails, as once the nails are cut the boards are ready to use.

After you have a quantity of boards you might like to grade them depending on how straight they are, the extent of any damage, and where you’ll use them in the project. You’ll be using the best boards for the floors so it is nice and flat. Any damaged boards can be cut down for use on the walls and around the windows.

Step 2

2/16The base of the cubby will be a full-sized pallet. Select a pallet with a solid construction as the floor.

Step 3

3/16Time to fix the upright posts. Remove the second board and second last board from the pallet with a pinch bar. For the upright posts we will be using 4 spare runners from a disassembled pallet. Take the four runners and mark the height of the base pallet’s runner on them. Countersink and pre-drill holes suitable for 75mm coach screws in the side of these vertical posts. Cut the tops at a 45-degree angle to suit a pitched roof before installing.

Step 4

4/16We now move onto laying the floorboards. Cut and pre-drill four blocks to support the first and last board in the corners with 75mm screws. Begin laying new boards across the length of the pallet fixed with 50mm screws. As you progress along the pallet you will need to remove the old boards and replace them with new boards butted up against the previous one. A small infill piece can be used to finish off next to the post.

Step 5

5/16Installing beams will give the frame rigidity. Take measurements between uprights and cut spare runners to suit width. Pre-drill horizontal runners and join uprights together with 75mm screws on all four sides. This will secure our posts together.

Step 6

6/16For the pitched roof supports, take four spare runners and cut one end of them at a 45-degree angle. Pre-drill them and screw the angled pieces together with 50mm screws. Install on the upright posts as the roof supports with 75mm screws.

Step 7

7/16Take three spare boards and cut to size for divisions where doors and windows will be placed. Pre-drill and screw into position with 50mm screws. Here I have created a door plus a window on the front and a door on the side. The door on the side will be used to access the shop section of the cubby.

Step 8

8/16Begin fixing boards to the walls. A brad nail gun will be helpful in holding the boards in place until they are permanently screwed in position with 50mm screws. Start at the base and work your way to the top of the walls. Take a saw and cut the overhanging timber boards flush with uprights.

Step 9

9/16Now onto the roof. Start placing and fixing the roof boards into position with 50mm screws or a brad nail gun. If the cubby is going to be in the weather, a sheet of builders underlay plastic can be added before placing the boards. Finish off the left-hand side of the roof line by cutting off the roof support then add the last finishing board.

Step 10

10/16To finish the roof, infill boards at the front and rear underneath the cubby roofline using 50mm screws or a brad nail gun. You will need to cut the tops at a 45-degree angle to suit the roof line.

Now you have completed the cubby portion of the project.

Step 11

11/16Time to build the shop floor, which will be made from three quarters of a full-size pallet. Take a full-sized pallet and with a saw cut off a quarter of it by sawing through the runners.

For the upright posts, we will be using four spare runners from a disassembled pallet. Take four runners, pre-drilling mounting holes in them as these will be the upright posts. Remove the first board and install the uprights in all four corners with 75mm screws. Once the uprights are in place, add supports for the first and last board. Continue to install floorboards in the same fashion as the cubby floor.

Step 12

12/16For the shop roof beams, measure the distance between the upright posts. Cut four boards to suit the length and pre-drill holes in the ends. Install them as horizontal supports beams on all four sides with 75mm screws.

Step 13

13/16A shop bench is a fun and practical addition. Measure the height at which you would like the shop shelf to sit. Cut and pre-dill three runners to a suitable length to fit between upright posts and then install them into position with 75mm screws.

Take spare boards and cut to length to suit shop counters. Fix them into the horizontal beams with 75mm screws.

To finish the corner of the counters, take a spare piece of board and screw it into the void between the shelves with 100mm screws. Cut a radius with a jigsaw on this infill piece.

Step 14

14/16Time for the shop’s wall panelling. Cut to length, pre-drill and install three beams with 75mm screws to make up the bottom surround. This will be used to fix the boards to for the wall panelling. You can now start fixing the boards around the outside.

Step 15

15/16Begin the shop’s skillion roof by cutting to length and fixing a beam to the high side closest to the cubby with 75mm screws. Lay your roof boards across the roof fixing them to the beams either side with 50mm screws or a brad nail gun. Once they are laid, mark a straight edge and cut to length.

Step 16

16/16You’re now the proud owner of a pallet cubby house with shopfront. You might choose to paint the cubby or even build additional elements like fruit and flower boxes, decorative cut-outs and doors. You could also decorate with curtains and other accessories. Adding the finishing touches is really up to your tastes and perhaps a good opportunity for your children to contribute some ideas to really make it their own.

Materials

Tools

- Approximately 12 pine pallets

- 50mm brad nails

- Treated pine screws sizes 10-8 x 50mm, 10-8 x 75mm, and 10-8 x 100mm

- 16 x 75mm coach screws

- Cordless drill driver

- Circular saw or Compound mitre saw

- Jigsaw or handsaw

- Pinch bar

- Hammer

- Brad nail gun (optional)

- Cordless reciprocating saw (optional)

Images

- Tags:

- Outdoor

You must be a registered Workshop community member to comment. Please join Workshop or sign in to join in the discussion.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

| Subject | Author | Posted | |

|---|---|---|---|

| September 2021 | |||

| July 2021 | |||

| November 2021 | |||

| July 2021 | |||

| January 2022 |