The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: Workshop shed build

Workshop shed build

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Workshop shed build

Some people go away for their holidays... and then there’s me, who takes four weeks leave to build shed.

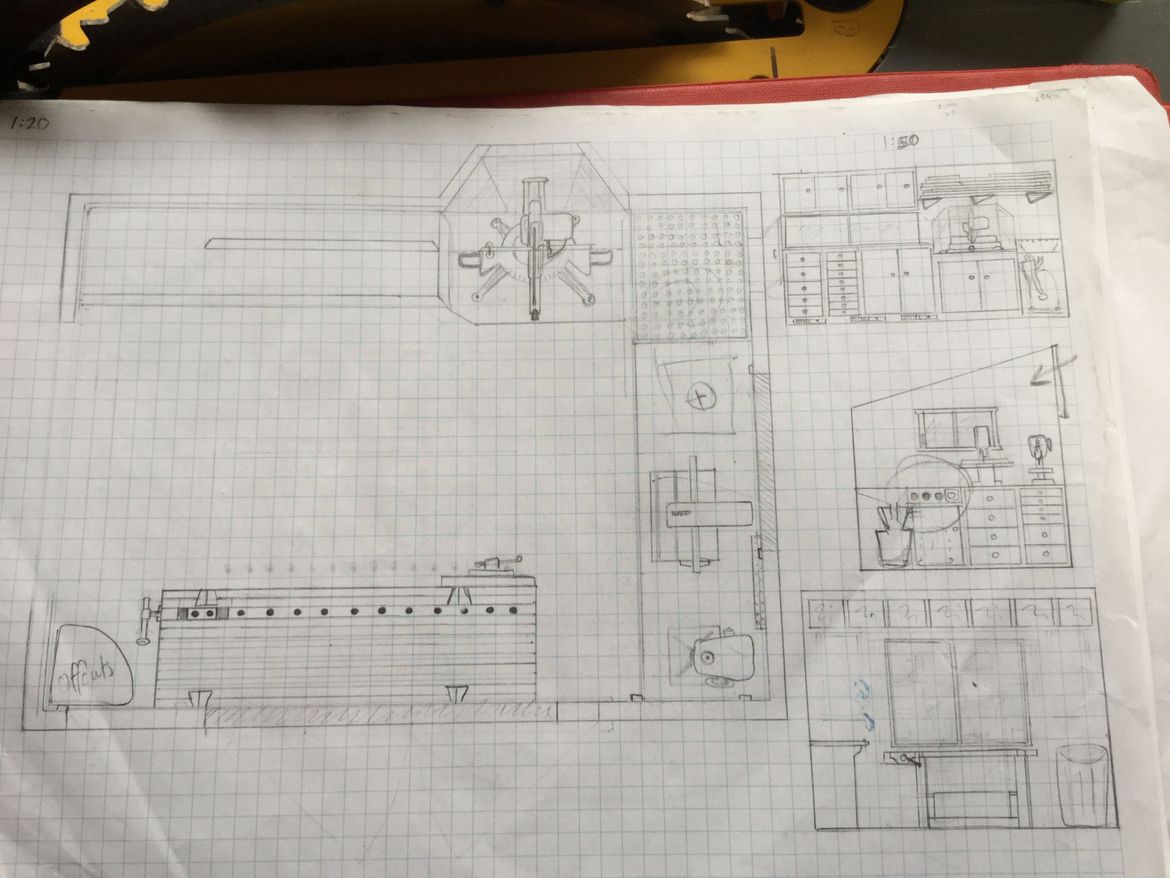

There was sort of a plan - a couple of drawings and some framing layouts, but nothing spectacular. After a year and a half of collecting unwanted timber, house wrap, insulation, Colorbond, trim, OSB and screws from local house construction, I was ready to go. Purchased some framing timber, flooring and timber for the subfloor, five sheets of OSB and the Ryobi 3 piece nailer / stapler set. Add two secondhand windows and assorted flashing and fixings, stir in a dollop or door hardware and cap with the 5.1m x 240mm LVL bearer I found on the side of the road.

Solved! See most helpful response

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Workshop shed build

It’s 3.6 x 2.7m to come in under the requirement for a permit, which is 10m2. Lucky we're metric, as 12' x 9' is too big!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Workshop shed build

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Workshop shed build

Downdraft sanding table is completely irrelevant given how wimpy my shop vac is and how much the table saw kicks out anyway. Table saw will go on a rolling stand (ragnbonebrown.com plan) and live under the bench that’s going on the west wall, with router mounted in the extension wing. This will all be 5mm higher than the workbench so I can use it as outfeed.

Mitre saw station will be ever so slightly right of where it is on the plans due to final stud placement. Hope that’s all clear as mud @Farside!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Workshop shed build

many thanks @Kiwifr33, clearly you have given this enough thought to have a scale plan. I find it encouraging you are not griping about space as my shed cannot be any bigger, possibly a tad smaller. I am also contemplating mounting tools on mobile stands so I can move them to an outside landing. I am thinking of adding solar PV panels and a couple of batteries to power the shed.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Workshop shed build

I have designs on a downdraft table 2000 x 600 with a dog hole top. Given that stuff will drop through the dog holes I may as well try collecting it while making it and it is a good test of the $48 bigW vacuums.

Only things that don't roll around are the Kreg Mobile Worktables, they have to fold up and be carried ( hopefully not too far as they are not light ) and my new today Bosch 18v wet dry extractor that will have a rolling base made for it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Workshop shed build

Thanks @Brad - do you have any advice on castors? The table saw will be around 30kg and bandsaw 40+, but I don’t want to break the bank. And in your experience are two locking castors enough?

Cheers.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Workshop shed build

Have you got any pics of the finished exterior of the shed @Kiwifr33? Be great to see it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Workshop shed build

Would love to @Kermit, but it’s still a work in progress

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Workshop shed build

Latest

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Workshop shed build

My Kreg router table roughly 900 x 600 has 4 locking castors and it's easy to move. Stable with all 4 locked, with only 2 locked it will move if you push on the free end. They are expensive...

Assembly table much the same size with 2 fixed and 2 locking, not so easy to move. Stable as the Kreg and set me back $35 for the set.

New bench 2000 x 600, given it would be hard to move at the best of times I am going with 4 locking at $22 each.

Table saw is 35kg and has it's dedicated fold up stand with 2 wheels.

Mitre sax is 32kg and has a fold up stand with extending arms. Folding it up can be an experiance...

I don't have a bandsaw but I think it being a square base you could get away with 2 free and 2 locking castors. Table saw fixed and locking is the cheap option or for easier movement 4 locking.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.