The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- How to mount post supports (stirrups) on...

How to mount post supports (stirrups) on a concrete slab?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to mount post supports (stirrups) on a concrete slab?

Hello. I'm building a carport. I need to mount galvanised post supports (stirrups) on a brittle concrete slab. Normal procedure would be to use Dynabolts, but I'm worried they will but additional unnecessary stress through the slab and perhaps crack it. Can I instead use an adhesive to anchor bolts in place (sometimes referred to as a 'chemical anchor' ) ? If yes, what sort of adhesive would be recommended ? Many thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Mounting post supports (stirrups) on a concrete slab.

Hassal147

There are heaps of products just for this. Mark your holes, drill out with a masonry bit. Clean out the holes fill with epoxy eg Ramset ultra fix plus or Ramset Cemset 101 masonry anchoring adhesive cartridge. Place stirups in place and push threaded rod to bottom of holes allow to set before tighten. Pushing rods through stirup holes helps avoid line-up problems latter. From memory we used the ultra fix plus and its nozzel mixed the epoxy for you as you inject it. I used cut threaded rod with nuts alread on them. You can buy sets of threaded rod with a notch just for this. You'll find all this stuff near dyna bolts in the aisle where screws and bolts are at Bunnings JDE

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Mounting post supports (stirrups) on a concrete slab.

Thanks for your prompt reply. Much appreciated. I'll let you know how I go.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Mounting post supports (stirrups) on a concrete slab.

"I'm worried they will but additional unnecessary stress through the slab and perhaps crack it."

I've had similar thoughts with Dynabolts, especially close to the edge and then someone introduced me to concrete bolts. I was skeptical at first, but as the Monkee's song goes - "Now I'm a Believer!"...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Mounting post supports (stirrups) on a concrete slab.

Hello @hassall147

It's great that you've received fantastic advice from @JDE and @Noyade. Both their recommendations are spot on. But since you asked about chemical anchors the Ramset ChemSet 101 Injection Kit or the Ramset 300ml Chemset UltraFix™ Plus are both ideal anchors for your project.

My number one tip to using these chemical anchors is to make sure that the holes you drill out for them are totally clean. If you have an air compressor and air gun attachment use them to blow out all the dust. Then use a bottle brush to remove any loose cement debris in the hole and blow it out again. You can also use a shop vacuum cleaner to suck out all the cement dust.

It sounds like a fantastic project, any updates you can provide while building it would be much appreciated.

If you need further assistance, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Mounting post supports (stirrups) on a concrete slab.

That's exactly my problem. The holes are going to be much closer to the edge of the slab than I would like, so I will definitely follow your advice. Many thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Mounting post supports (stirrups) on a concrete slab.

@hassall147 So did you go with the Anka Screws or the Ramset chemical anchor?

I'm putting posts up as well, would be good to know which options should I go with.

Thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Mounting post supports (stirrups) on a concrete slab.

Regards drilling (rotary hammer/SDS) close to the edge of concrete.

What do you guys think is "too" close?

I did this around 12 years ago. Both 10mm concrete bolt holes were drilled approximately 35 mm from the edge of the concrete. It's rubbish concrete that I laid 5 years previously.

I was 99.5% certain the concrete would split/chip/crack.

Amazingly - it survived.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Mounting post supports (stirrups) on a concrete slab.

Unfortunately, I'm waiting for Bunnings to re-open to the public before I can source hardware, but will go with threaded studs and a chemical anchor, not least because I've only got 65mm clearance between the bottom of the stirrup and the base plate. I want at least 100mm in the slab. I'll keep you posted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Mounting post supports (stirrups) on a concrete slab.

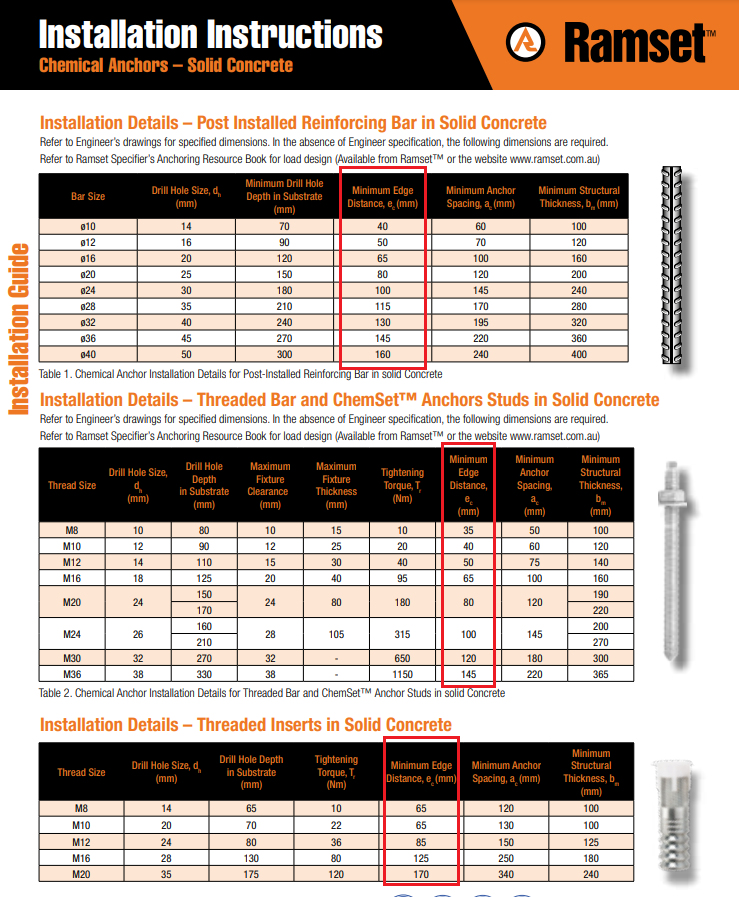

Here are the specifications from Ramset on minimum edge spacing. Using Ankascrews or chemical adhesives over Dynabolts gives more flexibility when fixing close to the edge of the slab. These min distances are specified so that the fixings meet their designed load ratings.

Mitchell

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.