The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: How to install exhaust fan in skilli...

How to install exhaust fan in skillion roof shed?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to install exhaust fan in skillion roof shed?

I want to cool my shed in summer and reduce condensation under the corrugated colour bond roof. Shed made out of weathertex. Not insulated at all.

My shed:

- 6m long 1.6m wide 1.9 - 2.2m high

- there is a wall divide to separate the pool equipment section from tool storage section. The dividing wall is 5cm from the roof, so there is a gap between pool and tool sections. The tool section is about 5m in length

I thought a solar exhaust fan to circulate air about may be better than Foilboards under the roof, If you agree that would work, would one exhaust fan on the tool end of the shed do, and if so, what size? Will the air gaps from the colour bond corrugations allow enough air flow in or do I need a vent somewhere, if so, where do I place that?

Solved! See most helpful response

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to install exhaust fan in skillion roof shed?

Hi @Ritar,

Installing a solar fan would undoubtedly assist with heat build-up in the shed, and I'd recommend a premium version like the Bradford CSR SolarXVENT 250mm Solar Powered Vent. Condensation forms due to warm, moisture-laden air hitting a cold surface. When the roof's temperature drops at night, the air inside the shed condenses on the underside of the roof. Adding a fan could potentially evacuate that warm air from the shed during the afternoon and reduce the condensation overnight. However, insulating the roof will likely prove to be a more effective solution.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to install exhaust fan in skillion roof shed?

Yes, I'm in Australia. Good reminder though about watching out for electrical wires, foil, nails....fraught with issues.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to install exhaust fan in skillion roof shed?

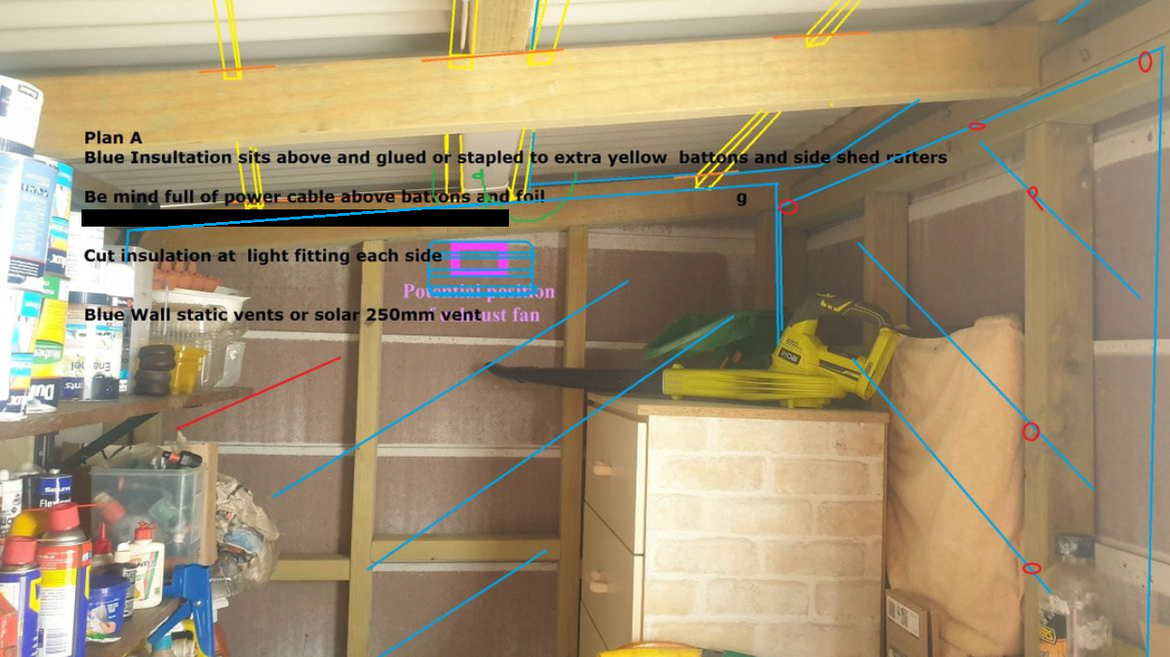

Please see some photos of the shed, inside and out.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to install exhaust fan in skillion roof shed?

Hi @Jewelleryrescue,

The reasoning behind the change in the Electricity Regulations 1995 mandating RCD's for Domestic Installations came about because of situations like this.

Mainly on lighting circuits, there was a 5 year old child that was killed in Rakaia when he climbed an Aluminium ladder put up against the house, no-one knew that the whole metal roof was live at 230V.

Some "electrician" had run a lighting cable with no Earth conductor to some outside lights, right under the roofing iron and screwed through it with a Tek Screw.

He never tested his work and the roof was live from there onwards.

The lights he had installed worked, so no issue with that.

An Insulation Resistance test would have picked this up and an RCD if it had have been installed at the time would have tripped every time, suggesting a serious fault.

That is a serious dropping of the ball, as it were.

Absolutely shameful.

Cheers,

Mike T.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to install exhaust fan in skillion roof shed?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to install exhaust fan in skillion roof shed?

that sounds good. Thank you all for your suggestions and warnings. It's back off to Bunnings I go. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to install exhaust fan in skillion roof shed?

Mitchell, just one more question- will this CSR Solar XVent just sit on the corrugated roof, or are you suggesting it go onto the northern end wall?

The sun disappears from this wall around 2pm so it may not be suitable to get enough heat out before the cooler evening.

What would be a wired version you could also recommend for this space?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Exhaust fan in skillion shed

Thanks Jewelleryrescue for the lead for EPE insulation rolls. It looks like it would be easier to install than stiffer foils boards.

When you say use builders glue, are you saying I glue it directly to the underside of the colour bond roof? Install it like a sheet, or follow the profile of the corrugated roof to minimise air gaps?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Exhaust fan in skillion shed

Hi @Ritar

Normally I would use foil to the outside of frame before the cladding goes on as this serves many purposes. info for new pre built shed owners

Such as a reasonably tight smooth fit and full insulation cover the screws through the cladding and foil will ground the foil to outer shed if metal lights and wiring will never interfere with foil insultation An additional Earth wire can be attached to foil back to the sheds sub fuse board. /so RCD can be in play.

@Ritar Your retro fit.

The EPE foam is not 100% stiff and can be spanned short distances over the roof, sagging wont look good , I want your shed to look good for you, too.

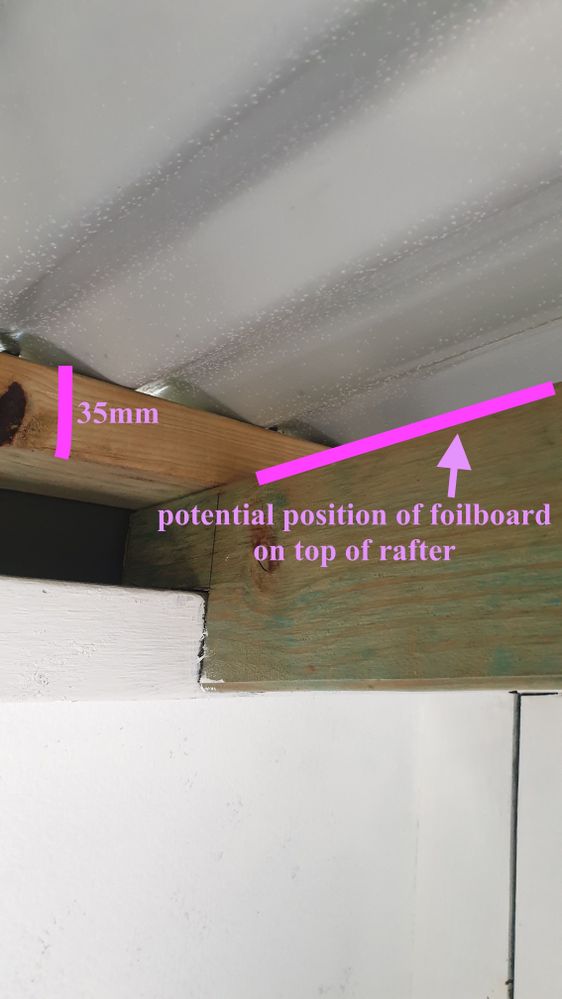

In the attached edited photo it shows extra roof battens level with the top of the beam to sit any insulation on flat.

OR Ok second thought you might as well put the battens on top of rafters as insulation will flex over the bumps. The more battens you have the less the sag in the insulation you can put glue on after foil is in place sqirt up on top of batton below insulation gravity will set it down to the batten . This wont look perfect but more industrial. So lets explore ideas more.

Flat internal roof

You could even use 4-6mm ply cut sheets and make a internal roof lining (painted? your choice) which will capture sandwich the insulation between the roof (and can breath via side roof corragations under the roof.. Screw the sheeting directly to the battons with the insulation on top with glue tack points just to stop it moving, See diagram blue roof panels Plus optional blue insulated sidewall flat lining or just insulation.

You maybe able to attach all this to existing timber side rafters or just add more battons. Center battens do not screw directly below side wiring. in case some one later uses long screw hits the wire.

A cant estimate how much clearance you have above the light fitting or if it is safe so probably best to cut around light fitting .

To be super safe contact a qualified electrician to verify your installation poses no risks.

Optional Static vents work 24/7 one at each end of the shed will cool as a though breeze and they are inexpesive this may be enough not to need roof vent.

If you later use roof vent place it as high as you can get in the ceiling in shed centre.

Please use this as a guide only to formulate your own design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to install exhaust fan in skillion roof shed?

The CSR solar vent would need to go on the roof, though I presumed you might be thinking of going with a powered unit on the wall, given your illustration, @Ritar.

Any of these slimline exhaust fans would work well for powered units.

I'll take this opportunity to remind our community members that a qualified electrician must complete all electrical work, including the installation of earth cables.

Mitchell

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.