- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

This big shed was taken apart, rebuilt with a higher roof and fitted out with a fresh epoxy floor, a new workbench and new shelving.

- The project

- The tear-down

- The epoxy floor

- The framework

- The wall and roof sheets

- Wrapping up the build

- The finishing touches

- More garage and shed inspiration

The project

When we moved into this house 10 years ago we had a 6m x 3m shed built in the backyard. We had been really happy with the shed we had built at our old house so we went back to the same company and said "Same again, thanks."

Well, we'd forgotten that we had the original built 2.1m tall, and the company didn't ask what height we wanted. When the new shed was built at 1.8m we had a problem – I'm 1.85m tall.

I put up with it for 10 years, ducking as I went through the door, and smacking my head regularly. But in recent years it really started to bother me and we started to explore options for fixing it.

The problem is that it was built like a big garden shed. There was no internal structure, and the Colorbond-sheet walls held up the roof.

Making things harder was the fact that the concrete was poured after the shed was built, and had probably flowed into the bottom C channel and around the screws at the bottom of the walls. So we'd have to screw the new panels into the old holes, which wouldn't be easy. We'd also had a concrete path poured out the front, so the screws on that wall were at or below path height, further complicating disassembly.

Talking it through with a colleague at work (a former boilermaker), he suggested we build a box from steel tubing and then rebuild the old shed on top, filing in the gap below. We could then screw into the new tube rather than trying to find existing holes in the concrete. Winner!

The tear-down

Having hit on a plan, I took detailed measurements of the existing structure, drew detailed drawings, photographed details, and labeled all the parts. As the plan evolved, less and less of the current shed would end up going back in the same place again, but I wanted to know where everything came from and how it was built in case we were unsure of dimensions during the rebuild. Once everything had been taken apart, it'd be too late – we needed to capture all of this while it was still standing.

Then it was demo time. Piece by piece, starting with the roof, it all came down and piled up on the lawn.

The epoxy floor

Since the old concrete slab was in good condition and fairly clean, I decided to epoxy the floor. I figured that while there were no walls, and lots of fresh air, now would be a good time to do it. Following the directions, I etched the slab and applied a coat of epoxy.

It looked great when it was done, but a few months later it was looking a bit dull and blotchy. In hindsight, I think I'd do one heavy coat at the end.

The framework

Next we bought about 70m of 40mm x 40mm square tube. With the assistance of a few friends and a welder, we set about kitting up all the parts we'd need for the new framework, then assembling it all on site.

By this time our original "build a box" plan had evolved into something more complex. We decided to shorten the doors because leaving them at full height would make them too tall when it came to reaching the pad bolt at the top of the second door. We also decided to add additional structure to the corners and along each side to both reinforce and give us something to hold the roof up without relying on the wall panels.

The gap between the middle rail and the floor is the roughly 600mm of height that we added. The welds were all cold galvanised to prevent corrosion, and the visible portions of the frame painted to match the paperbark-coloured sheets that would go on later.

The door frames went back on to check the fit (we used the original frames, and added roughly 300mm to the height). We also reinstalled the window, both to check the fit, and because I didn't want it to get broken laying flat on the lawn. You can see that the original roof framework was reused as-is.

The wall and roof sheets

The next thing was to make it look like a shed again! We bought brand new 2.4m sheeting for the two most visible sides (towards the house and lawn) so that they'd have a nice clean look.

The old sheets from those two sides were cut into 600mm "mini sheets" and used to fill the gap when the original sheets were re-hung on the back and fence sides. Since those sides aren't really visible you don't notice the join, and we saved a fair bit of money by only buying new sheets for half of the shed.

We started on the short, simple side (closest to the lawn) then worked along the back and down the fence. We left the front (with doors and windows) for last.

I also installed brackets and timber studs for pegboards and tool storage into the framework before we sheeted each wall. Having access from both sides of the frame made drilling and screwing the brackets into the steel much easier than working against a steel sheet.

The roof, ridge capping and gutters went back on without a lot of drama. Everything was labeled, and went back exactly where it came from.

Putting the door skins back on the door frames was a challenge. A large sheet-metal brake to bend the sheets around the frame would have made the job much easier. But we got by with clamps, brute force, a rubber mallet and some swearing.

We had a flat flashing panel custom-made to the right dimensions to go above the door and create a lip so that water wouldn't drip and run down the back of the doors.

Wrapping up the build

After that it was all finishing work. The original design had the wall sheets fitting together nicely and screwed at the corners. But subtle changes in fitment and dimensions meant we couldn't easily do that on the new version. So the final flute in each sheet was lopped off with the grinder and new flashing installed on each corner to cover the cuts.

The original flashing was reinstalled to cover the peak in the roof. Downpipes were reinstalled, and the rainwater tank put back in place. The added height meant we needed to add a short length of pipe, as the outlet was about 600mm above the tank. We also pinned the concrete slab with star pickets, built a retaining wall, and barrowed in about a tonne of road base to try and stop the slab escaping downhill.

The original epoxy job on the floor was either applied too thin or didn't like being in the summer sun for a few months (probably both), and was looking a bit patchy. It was OK, but we had enough unmixed epoxy left over to do a second coat. This was applied much thicker, and it looks great. It's got that real smooth sheen you see in a professional workshop.

The finishing touches

During the build we'd had a couple of wet weekends where I couldn't work on the shed proper, so I'd built a 3m workbench out of the leftover steel from the frame. This went along the short side of the shed inside the door. We cut benchtops and fitted those in place.

My cordless drill station was finally hung. The electrician came back, reconnected power, and installed additional power points and lights. We built shelves, and moved everything back in.

Now I don't hit my head on the roof any more, although I do still duck going through the door – old habits die hard.

New shelving lets us make much better use of the space we have. Nothing lives on the floor any more, and I've got some actual workspace for projects. The project is a great success!

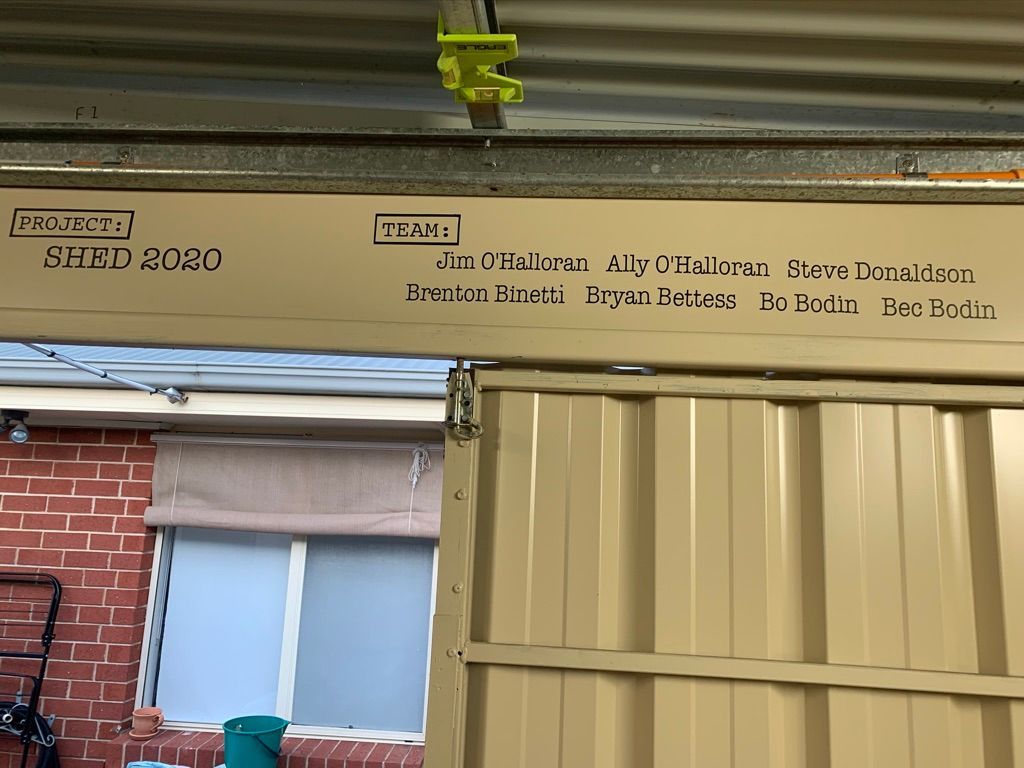

All that was left was to ask my wife to break out the vinyl cutter and acknowledge the great friends who helped make this build possible...

Here's a video of the whole project from start to finish.

More garage and shed inspiration

Bunnings Workshop member Jess put together this brilliant video tutorial and step-by-step guide: How to apply epoxy to a garage floor.

Experienced workshop member Peggers put together another great step-by-step guide: How to build garage storage.

There are also plenty of great ideas in our Top 10 garage and shed projects.

Let us know if you need a hand with your project – we're here to help.

- Tags:

- Garage and Shed

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Wow, what a professional job. I love how you acknowledged your team with their names, I'd be happy to work with you as a manager. I'm sure you're enjoying your project and are rewarded every time you duck through the now right-height doors.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Absolutly brilliant!, Nice work in documenting what you took down and reusing it all ![]()

Especially love the bit in the video that said "No bits left over" hahaha Its what we all wish for!

Definently a nice workshop fitout.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi @Dave-1

Let me tag @jimohalloran to make them aware of your kind words. I think it was brilliant that they sealed the slab first before rebuilding any of the structures. The steel frame certainly made re-assembly a much easier job.

Eric

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

| Subject | Author | Started | |

|---|---|---|---|

| February 2023 | |||

| July 2022 | |||

| December 2023 | |||

| November 2022 | |||

| March 2023 |