The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Featured Projects

- >

- Glass-fronted overhead laundry cupboards

Glass-fronted overhead laundry cupboards

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

These elegant glass-fronted custom laundry cabinets provide plenty of much-needed storage.

The project

I made these cupboards using 16mm melamine sheets for the carcasses, Tasmanian Oak for the doors and Broadline glass.

I had to router the sawn edges of the melamine to tidy up the chipping.

Carcasses built. I made them in two parts for ease of lifting and installation.

The doors were made from Tassie Oak, 42mm x 19mm DAR.

I routered the sides to match the doors on the existing laundry cupboards.

Sample of Broadline glass for the cupboard doors.

Making and gluing the timber panels for the sides and bottom of the cupboards.

Installing the Hafele hinges.

I drilled too many shelving holes. Lesson learned – only drill what you need.

I made the doors about 12mm longer than the cupboard so I don't need any handles. It also looks neater.

Installing the cupboards. Note the homemade overhead cupboard jacks. They were just right for the job at hand.

Carcasses installed.

Now I just needed to install the bottom panel and two side panels.

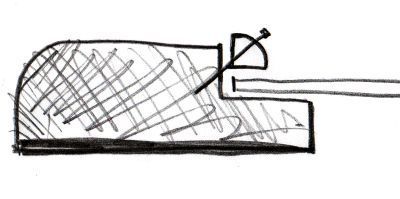

To make the stiles and rails for the joins in the doors I used a router table, two router cutters and jigs that I made with the help of ideas from YouTube. I know that you can use a table saw to make the stiles and rails but I have never tried it. My saw is not that good.

I started learning to use these type of power tools in the last couple of years. I say have a go. If it fails you can always make another one. There's nothing more pleasing than when you get to see the final product.

This is my D.I.Y. router table with a Makita variable-speed hand router mounted under the router plate.

Router bits for stiles and rails.

Jig to cut stiles on router table.

Another style jig for cutting stiles. I find this one much easier to set up and use.

I decided against gluing the top rail of each door in case I need to replace the glass if it was broken. The glass fitted in nicely in the 6mm grooves on the doors.

As you can see in this photo I used small brass screws to hold the rails in place. If this doesn't work I will have to glue them in place.

I coated the cupboards in Bondall Monocel Clear Wood Varnish, Satin. It’s water-based. Good product, reasonably priced too.

Before and after

More inspiration for your laundry

Experienced Bunnings Workshop contributor Adam_W has put together this handy guide to planning a laundry renovation.

You can also check out our Top 10 most popular laundry renovation projects and Top 10 most popular storage projects.

Let us know if you need a hand with your laundry project. We're here to help.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

@JoeAzza You are an inspiration mate. This looks sensational 😃

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi @JoeAzza,

Looks superb! 👍

I'd like to try something like this in our laundry, but on a smaller scale.

The glass - where did you get that?

The router blades - are they sold as a set? Bunnings? Are they 1/2 shaft?

Do you think I could make the router cuts on a small router table without the gigs and rigs?

The router under my table is only 900 watts - enough power to get through hardwood?

Cheers

Graeme.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi @Noyade

Thank you Graeme and @mich1972 for your comments re laundry cabinet.

To answer your enquiries

Q. The glass, where purchased ?

A. I purchased from a local glass wind repairs shop, the glass itself is called Broadline Reeded glass, (20mm center gaps)

Q. The router blades - are they sold as a set? Bunnings? Are they 1/2 shaft?

A. The Stile and rail (tongue and groove) cutters are for 19mm thick timber, with a 1/2inch shank, available from Ebay or Timbecon, which is also online

Q. Do you think I could make the router cuts on a small router table without the gigs and rigs?

A. The router under my table is only 900 watts - enough power to get through hardwood, I would definitely recommend making a jig for this kind of routering to hold and guide the timber on a router table.

The router I used is a Makita RP2301FC 3 -1/4 HP Router, 2100 watts, I'm not sure if a 900 watt router would take a 1/2 shank router bit or have the power to cut hardwood, maybe @EricL might be able to answer this question.

If you have a table saw, you can cut the stile and rails using the saw, there are many you tube ideas that you can look at. Here is a link to one of them.

Cheers

Joe

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Thanks for your detailed answers, Joe.

Unfortunately none of my tools would have this degree of accuracy, especially that table saw seen in the video clip.

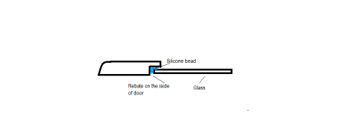

I'll possibly try a rebate with some sort of small quad molding to hold the glass or more likely, plastic, in place.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi @Noyade

I like your idea to rebate and put beading around the frame.

You could also make the door frame , the rebate the inside of the door, then just put a silicone bead around the edge after the glass and frame is fitted, I suggest you finish coat the frame of the door before fitting the glass.

A glazier can fit and silicone the glass to the door for you if you ask them to do it.

Good luck.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Thank you for the very detailed pictures - beautiful cupboards. Have bookmarked for future reference ![]()

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects