- Bunnings Workshop

- >

- Featured Projects

- >

- D.I.Y. home office desk using Beech pane...

D.I.Y. home office desk using Beech panel

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

This sturdy home desk was sanded super-smooth, fitted with a cable tray and finished with a wax polish.

The project

With all the working from home in the past couple of years, it was time to upgrade my humble home table to a decent working surface.

Materials

This is what I used for the project:

1. Beech Laminated Panel - 2200 x 600 x 26 mm

2. Zenith 8G x 20mm Gold Passivated Button Head Stitching Timber Screws - 100 Pack

3. Bondall 500ml Monocel Timber Bench Top Oil

4. Trojan 140mm Surshape Plane

5. Sandpaper: 80 grit, 120 grit, 240 grit and 400 grit

6. Gilly's 200ml Clear Carnauba Polish

7. Ikea Adils legs, black

8. Matrix Cable Organiser Tray Black

9. Various tools and bits and bobs.

Steps

Renting in the city means I have no workshop space, so my balcony was commandeered for this work. The first step was the first (of many) trips to Bunnings to get all the stuff.

The Beech wood panel was cut down to 1300 x 600mm for the desktop. I'm not sure what to do with the other pieces. I'll think of something later.

All the materials ready to go.

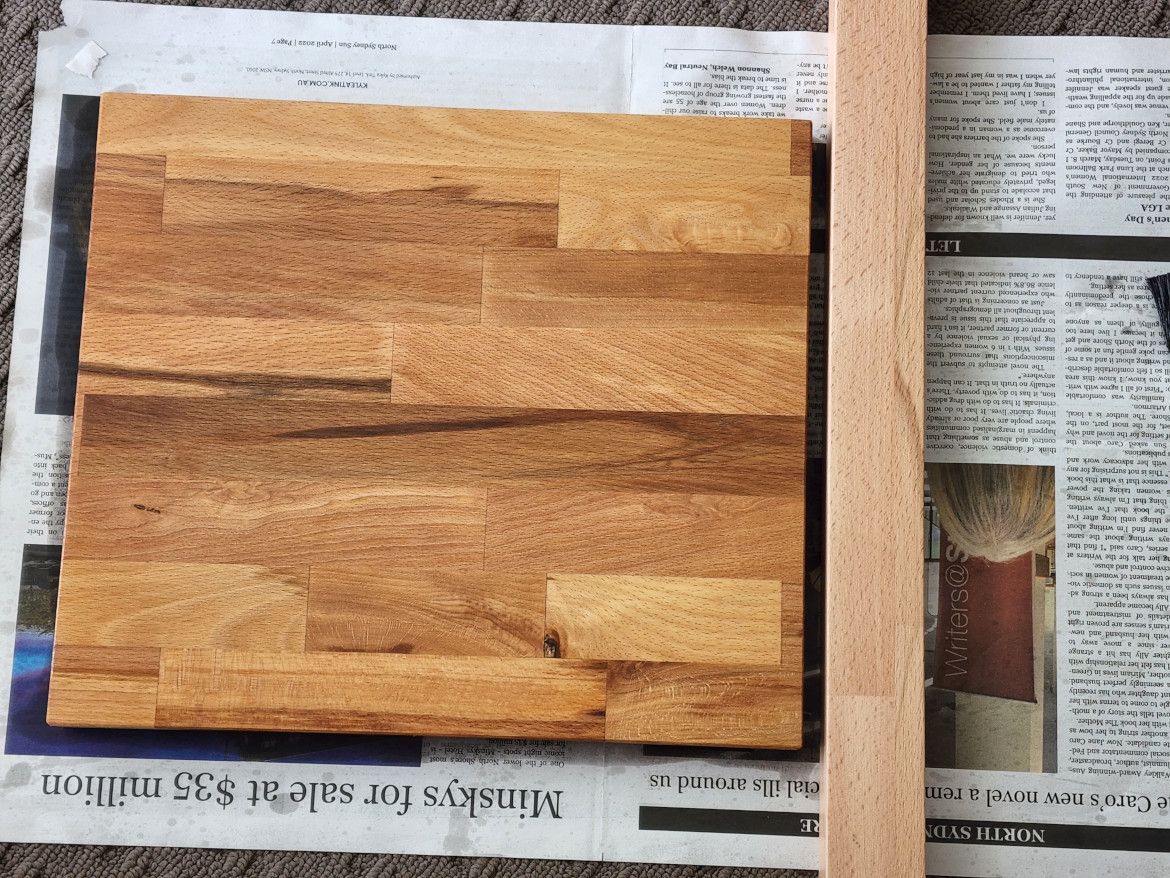

I did a test coat on the offcuts: the Bondall Monocel benchtop oil on the left and Cabot's 250ml Clear Water Based Cabothane Interior Varnish Matt on the right. I liked the Bondall oil more and went with that.

The next step was sanding down the panel to a smooth finish – I started with 80 grit, then 120 grit, then 240 grit, then 400 grit for a fine, smooth finish. Doing this manually without a sander was a real workout!

The edges were quite sharp, so I used the Trojan Surshape plane at a 45-degree angle on the edges to round them out just a little bit and sanded it down to a smooth finish.

Once it was sanded, vacuumed and cleaned thoroughly, I applied three coats of Bondall Oil, allowing it to dry for about two days between coats. It was rainy in Sydney so it took longer to dry.

I rounded off the edges slightly.

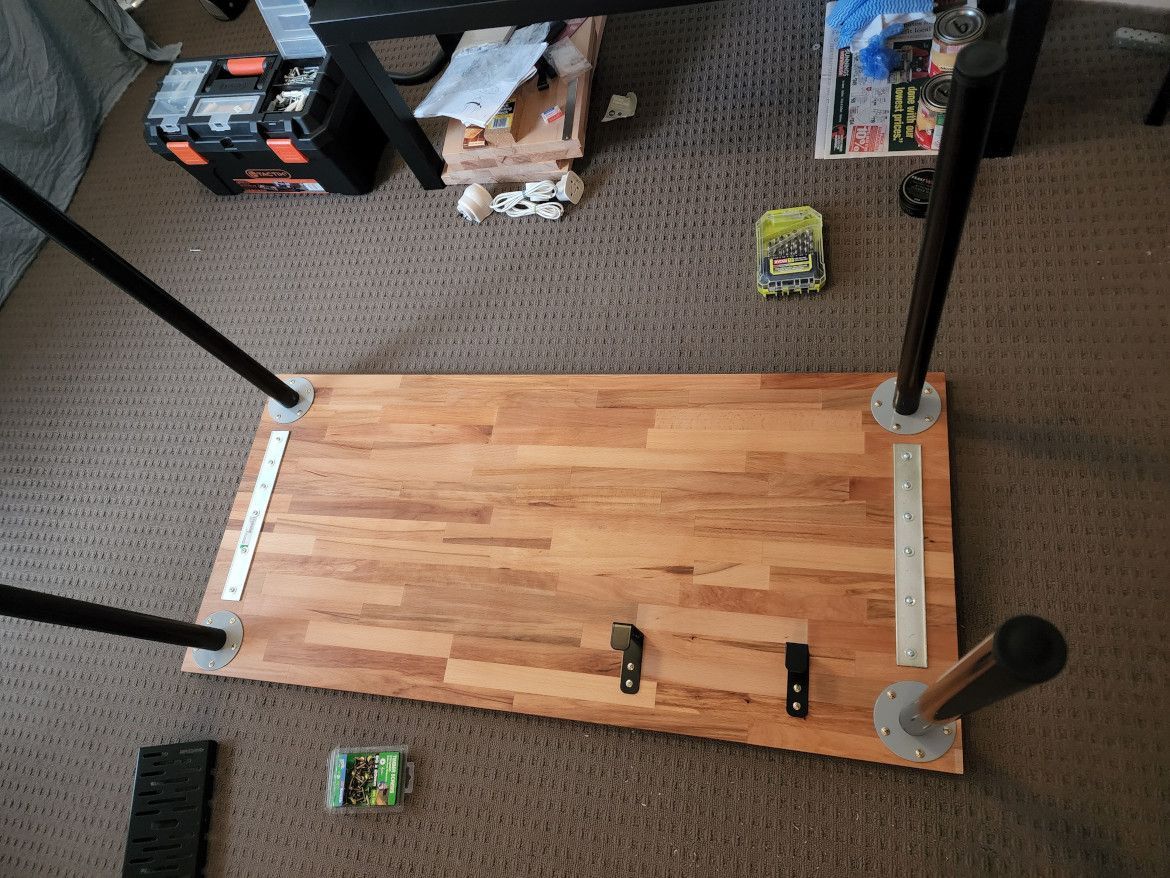

I set the mounting plates 6mm in from the edges.

I attached a bit of tape to the drill bit to indicate a depth of 19mm to drill the pilot holes for the leg plates.

Leg plates attached.

I waxed both sides of the panel.

I noticed the panel was warping a little, by about 2 mm on one side, so I attached a Carinya 340 x 40 x 3.5mm Zinc Plated Mending Plate - single at both ends, which straightened it out. Hopefully it holds!

I also attached the cable tray on the underside. Then I flipped it over and gave it a final wax and left it to dry for two days.

All finished and ready to use.

These panels are very versatile. I wish they came in different thicknesses.

The next project is a drawer cabinet on wheels for under the desk. I would would have loved to use the Beech panel for this too but 26mm is too thick for an under-desk drawer.

More home office inspiration

Bunnings Workshop member MyKindofBliss set up workspaces for two people in this coastal home office makeover on a budget.

Workshop member robchin took just an hour to build this simple and spacious desk using a SpecRite Teak Panel and RapidMesh Furniture Legs.

There are also plenty of great ideas in our Top 10 most popular desk projects and our Top 10 most popular indoor furniture projects.

How to build a desk

Experienced Workshop member Peggers shared a step-by-step guide to building your own desk.

The Bunnings team has also shared these helpful guides to get you started:

Let us know if you need a hand with your own project. Start a discussion and tell us what you need.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

@vr_sydYour project looks great, well done! I also want to say a huuuuuge thank you for such a detailed post showing all of the items and steps you took, this is really worth it's weight in gold because it gives folks like myself that 'ah haaaa, so that's how you did that' moment 😃

Cheers,

Jason

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

@BoeingFan Thanks for the kind words Jason ![]()

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects