The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Featured Projects

- >

- Bench seat using Pine sleepers

Bench seat using Pine sleepers

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

An outdoor bench seat made using three Pine sleepers. Build your own following step-by-step instructions.

The project

This bench seat using three Pine sleepers (2400 x 200 x 50) took about three hours to build from scratch after putting the sleepers through the thicknesser. I could have made the ends simpler, but I like the look of the wedges. All materials are from Bunnings, and I finished the piece with Bondall Clear Gloss.

Just watch out for a bit of a warp along the seat if the piece will always be outside. I used a couple of concrete blocks to keep mine straight.

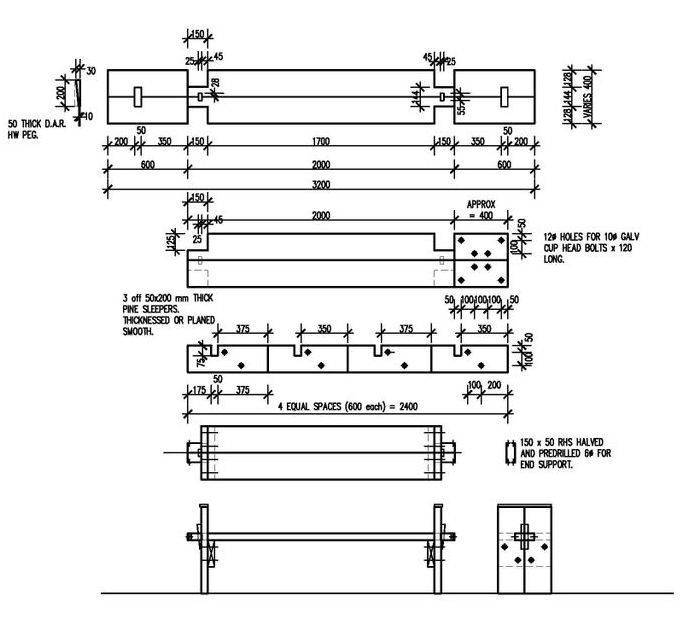

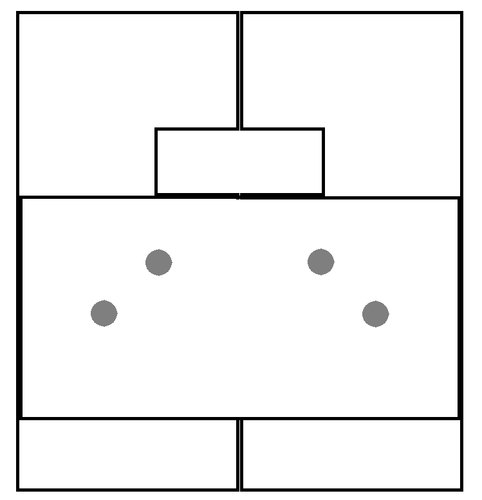

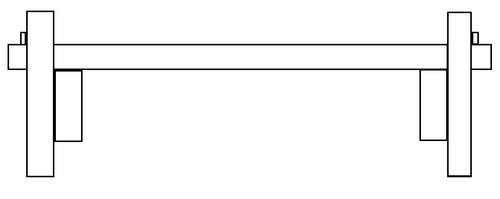

Here is the original design:

I updated the design to include a back rest and found it to be a lot more comfortable using four sleepers instead of three.

How to build this bench seat

Since this has been a popular project within the Bunnings Workshop community, resident D.I.Y. expert Mitchell put together the following instructions based on the original plan shared by cadsman.

Materials

- Three lengths of 200 x 50mm 2.4m H4 Ironwood Classic Treated Pine Sleeper

- Eight Zenith M10 x 120mm Hot Dipped Galvanised Cup Head Bolt And Nut

- 25mm metal strapping.

- Four 40mm timber screws.

Tools

Method

Step one

Take two of the sleepers and cut 400mm off one end. These longer 2000mm sections will be the bench seat and the shorter 400mm sections will be the brace for the legs. Take the third sleeper and cut it into four 600mm lengths. These will be the legs.

Step two

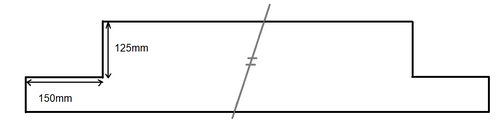

Cut a rebate out of both ends of the 2000mm bench seat sections. The rebate will be 150mm from the end and 125mm wide. This rebated section will fit through the legs.

Step three

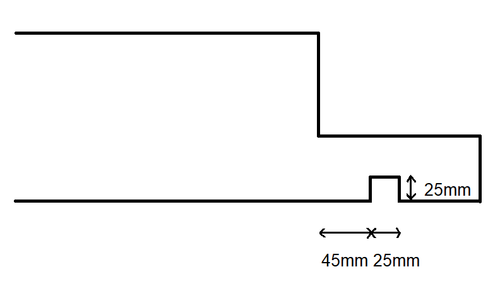

Cut a notch out of both ends of the bench seat sections. The notch will be 25mm x 25mm and is 45mm from the end on the rebated section. It can be created by making two parallel saw cuts into the timber. Once the timber is cut using a chisel, remove and clean up the notched section. This notched section will have a peg placed through it to secure the bench to the legs.

Step four

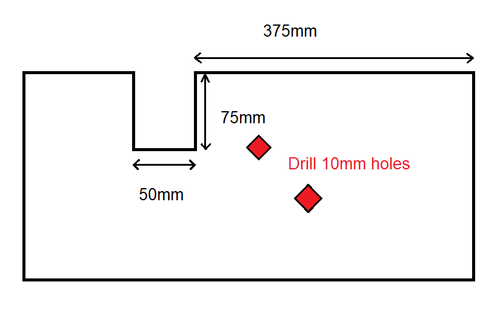

Notch out all four leg pieces. The notch will be 75mm x 50mm and is located 375mm from the bottom of the leg. Drill 10mm holes beneath this notch for attaching the braces.

Step five

Take the two leg halves, placing them together, and place the 400mm brace section directly below the notched out portion of the legs. Drill four holes in the brace, matching the locations of the holes already in the legs. Insert your bolts through the holes and tighten the braces into position.

Step six

Insert the bench section rebates into the notched section of the legs. Take an offcut of timber and create two wedge pieces to lock the bench together. The wedge will need to be 50mm x 25mm and tapered to suit. Since this bench is made from Pine, it is advised to nail in some metal strapping to prevent the wood splitting when hammering in the wedges. If the bench is not completely solid, add some additional timber screws through the joined section to assist.

More furniture projects

Workshop member AndrewJones crafted this bench seat that features mortise and tenon joints using hand tools.

It can be surprisingly easy to create an attractive and functional piece of furniture for your home or outdoor areas. Find ideas for your next D.I.Y. piece in our top 10 most popular indoor and outdoor furniture projects. You can also get great ideas from our Top 10 most popular woodworking projects.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Love that wedge to hold the seat together. Also impressed with the no wastage! I have been trying to figure out some bnch style seating for outdoors and this looks like a good option. Do you have an updated photo withthe backing you mentioned?

Dave

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hello @Dave-1

Let me tag @cadsman to make them aware of your kind words and question. While we're waiting for an answer, I've drawn up a quick render of the plans of the chair to give you an idea of what the backing might look like.

If you have any other questions we can help you with, please let us know.

Eric

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Here is the pic with the back on.

I have found that a 15degree slope to the backrest is about right for comfort.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi Eric, I won't be staining or treating the seats, just let them weather as they go. I like the colour as they spend time in my Pizza Pit.!!

Cheers IanK

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

I do like the weathered look as well, The seating and table I want for my frontyard will have that type of look and feel once I get to make them! I really like that sloping back of the seat. I do have a question about it tho, Does it make it top heavy when you lean back in it or is the sloped back too shallow to impact?

Dave

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

The sloped back at 15 degrees let's you lean back without tipping the seat. I have had the grandkids crawl all over and try to tip, but they can't. So the backs are fine.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects