The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Bathroom and Laundry

- >

- Re: Shower liner to go on bowed drywall

How to install shower liner on bowed drywall?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to install shower liner on bowed drywall?

I've watched several DIY shower unit installs. I'm getting a plumber to do most of the work since it's the first time working with such units, and there was existing bath/shower combo pipe work to be removed or rerouted.

But I've got the drywall sheets up (aqua"gib"-like product). And despite many many measurements and careful sanding, it turns out the old timber frame is concave-bowed in the middle. Stud is 2400 (ie 2410mm ceiling). top and bottom line up, but there's a 5mm gap in the corner. My level is about 750mm long, and in every plane and along every stud and dwang/nog, it tested as true and flat before I put the drywall on. Vertical, horizontal, diagonal. Only a few peeks of light at the joint gaps. But put the drywall sheet on - lo and behold, 5mm bow in the center of the mixer/shower head sheet. I've haven't got a third sheet into the tiny room to check the second wall.

Is it savalageable? What can I do? it's a two sided liner with moulding to go in. I REALLY don't have cash to pay a builder or anyone else (a $10,000+ bill elsewhere to pay).

How can I not get such bow in the future - I checked this _dozens_ of times, paranoid level of checking.

And what is the fix? It's a multistory house, with handiplank wall, and I'm not going to replace the whole stud (@ good chunk of wall).

- Labels:

-

Plumbing

-

Renovation

-

Tools and Materials

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shower liner to go on bowed drywall

Welcome to the Bunnings Workshop community @mist42nz. It's brilliant to have you join us, and many thanks for your question about installing drywall.

It sounds like the best solution here would be to remove the sheeting and address the bowed stud. If it's only out by several millimetres, you might be able to pull it back into place and install additional noggins/bracing to fix it in place. Alternatively, I'd suggest taking a planer and fashioning yourself a packer that fills the concave-bowed section. The easiest option might be to adhere a square section of timber to the stud and then plane it down.

It sounds like a 2400mm straight edge to check the rest of the walls would be a good investment.

If you could post some images showing the issue, our helpful members might have other suggestions for you. Shout out if you need a hand uploading pictures.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shower liner to go on bowed drywall

Hmm the 2400mm straight edge is a lot cheaper than I thought. When I did my training (many years ago now) we used to use a concrete screed bar, and they were expensive so I never got one. I used my level (750mm) and a piece of timber. Couldn't get full access due to the old mixer and shower head, but there's a lot of timber in that showerhead wall, since the garage roof (the garage is lower on the section) meets about a meter up the wall, so there's a lot of bracing for that, as well as the old bath bracing and for mounting taps, mixer, shower head, and the new mixer and new sliding rail.

Thing with ripping out the drywall sheets, and screws, and glue, and fixing the stud, is how to get the right measurement. The top and bottom are fine, but the middle not much more that a 5mm shim at the middle.

But looks like I finish the attached laundry and then demo this attempt for the shower, and go over it with that 2400mm straight edge - build it all out 5-10mm, then sand it back to a marked (straight) line. Bit annoying because my table saw is on the fritz and it's going to be a couple of months before I can afford to replace it (it tends to jump a tooth, and I suspect the blade has some angle on it. 20 years will do that)...

Thanks,

Carl

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shower liner to go on bowed drywall

I can imagine it's a frustrating experience, @mist42nz. Likely best to sort it now rather than installing the shower and then running into further issues. Having to remove the shower would be a lot worse.

Let me mention a couple of our knowledgeable members, @TedBear and @Jewelleryrescue, to see if they have any thoughts.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shower liner to go on bowed drywall

So your wall is bowed inwards approx 5 to 10 mm at the middle if I am reading your post correctly and the top and bottom at level with each other?

A bow in a tiled shower would really stand out tiled directly on to that wall so you are right in wanting to address this issue.

Traditionally you would need to remove dry wall and find the studs bowing inwards carpenters would level noggings first, cut the stud halfway though at 45 degrees and pull the stud into straight and add timber plates to each side of now straight stud to restore strength to stud.

You said top and bottom plate are good so you can use a standard string line if you have obstacles on the wall to find areas to build it out. might be suitable. The old gravity plumb line with a flat washer for a plumb can check wall verical at the same time as wall straightness.

No doubt you screwed and glued the dry wall as any one would. I am just tring to rememeber the rules about showers can a second sheet of villaboard be added if you do not want to remove the first sheet. Some one correct me on this if I missed a memo. I think your good you can add a 2nd board and shim it out at the middle after using a string line or straight edge.

But beware if you tiling floor to ceiling as the weight of the tiles need to be well supported by any packing efforts and extra screws used into wall panels.

if it is your property you can decide to use shower wall panels covering the bow and packing it out behind or maybe your adding a modular shower with its own walls. You need to decide if you will be happy with your job in 20 years time or not let yourself guide you the most I think you already know what to do before you asked I hope talking about it makes your decision easier.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shower liner to go on bowed drywall

turnings out those Straight Edges aren't available in the New Zealand Bunnings stores - ended up having to pay $160 for a 2.4m concrete screed which was closest they had.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shower liner to go on bowed drywall

I agree. but it's also how best to do it. If it was convex and bowed into the room I could sand it back. but top and bottom line up, but how to pack the 5mm in the middle and out to 0mm at the ends, solidly enough for a shower room. Also not tile, liner for cabinet style shower. But the other limitation of course, is bathroom so the area is tiny, and it's a refurb, not a new install so I can't muck around too much without damage older wall/weathertightness etc

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shower liner to go on bowed drywall

it's concave, and I'm fitting a tray and fibreglass liner, not tile. (modular). I'm a trustee so technically it's my place and I get the say on what happens and have to foot all the bills, but I'll never be there or use it. That means also a degree of idiot proofing (another reason for not tile).

I could slap on more layers, but it's already small room (having to overlap and block out 100mm of a window already).

being concave it bows away from the room. if it bowed into the room I could just sand it back.But on my level it showed as straight and flat (over the 750mm). I had tried a weight on a string line, but with the breeze and few other factors it didn't really have accuracy in the middle of the wall for this job.

Bunnings New Zealand don't sell a 2.4m Straight Edge, and I had used a bit of kiwi 4x2 to check it , but NZ timber is crap so it was more bowed, warped, and cupped than the wall.

But real puzzle is once I get that sheet ripped out, when I use my new 2.4m concrete screed ($160) to give me a straight line, how do I get a straight line that is secure enough to do the job. it's 0mm at the ends and 5mm in the middle and has to last. And as mentioned this is a multi-level and refurbish job, so I can't cut and wedge it without risking damage to garage roof (which is on the other side of the mixer), and all the rest of the timber in the wall (it's over 30% solid wood already, with the various bracing, packing, screw fixing points, and roof backing/packing for where the garage roof attaches about 1m of the floor - so running a second board upside the stud is totally out. but if I use a 0-5mm shim is it going to be strong enough backing for the aquaboard and shower liner, since people are going to be constantly leaning or pushing on it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shower liner to go on bowed drywall

Hi @mist42nz

I hear you about having to buy tools for potentially a one off deal. I had being there done that for me personally i am glad I bought tool because that job because I know I used my best skills. you might be glad you own it down the road for other uses. I found a straight bit of 2M pine I i guard with my life and keep it sitting flat and out of the weather as I don't own aluminum screed either same boat as you really. If I didnt have that lump of wood i might have to buy a screed straight edge too.

I hear you not able to cut wall etc and I agree, and yes 5 mm timber or aqua board offcut shim will be fine under the aqua board glued and screwed in place. Even 2 times shim on top of each other will be fine against normal wear and tear , Plus you using a fiberglass liner over wall into the base that will flex and absorb alot of people movement before the wall is even touched.

Question : Wont the fiberglass liner cover the wall in question? Wont it hide the 5mm bow I need to tell you no house ever I have seen is 100% straight ( even 2 million dollar houses I used to detail/ finish) If you wish to let this bow slide no one will notice as tiles not used. Can you see any one refusing to use the shower as there is a slight bow on one edge? If the bow is slighly visable at the edge of the fiberglass liner add a bit of quad trim along the edge.

Your the person that needs to assess the bow visability and correct it as you need to to meet your standards. Your the trustee, in a heritage place I would fix it.

Another angle is how big a bow is it area i mean is gyprock plastering it to big an area?

But Dry wall removal option:

in a nutshell . I would use your straight edge and find any stud high points first then measure and find any low points across timber and add packers untill your straight edge or string line(if plumbing in the way) says flat.

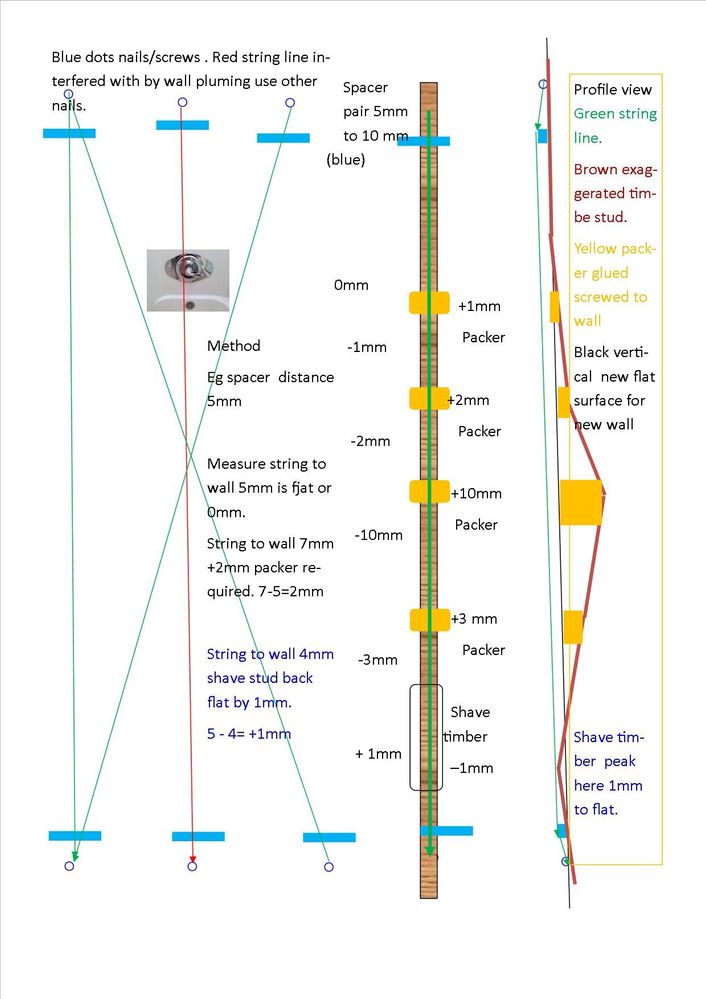

Wall levelling (see drawing might show you quicker.)

You where asking how to do this even if you know other readers might benefit.

I would put 4 or more small nails or screws 4 top 4 bottom of the wall and start a vertical string line on the edge moving across 4 approximate vertical lines across the middle. or across each and every stud in wall. Tip: tie a open non closing loop in end of the builders string ideally so it is easy to move from screw to next screw testing the wall. Easy way is to loop screw 1 at top , wrap string around screw2 bottom and wrap 2nd time another screw to hold suitable tension Push the string flush to wall with you straight top bottom rails and dont let string be obstructed by any thing in its path like the outlets. if outlets hinder straightness move nail or move string at diagonal. See diagram red (bad) and green ok Now tuck any spacer of the same thinkness at the top and bottom of the string. this will hold it off the wall incase it bows out touching the string.

Now measure from the string line to the wall or wall stud timber. EG 5mm spacers ( this means subtract 5 mm off your measurement of 5mm and that is a flat wall spot no spacer required. 5mm- 5mm is zero) ok wall is flat at that spot . If you measure 8mm that means the wall or stud is moving away (bowed inwards from straight by 3mm (8- 5mm space is +3mm that means add 3 mm spacer here (Tip write this +3 on the wall as you go. ) The more timber in the wall the more places to fix more shim glued and screwed the more packer points the firmer the wall this dosnt matter if wall has only studs or a pre existing wall. (Preexisting wall find studs to do string line and attach packers too) If you have a 5 mm spacer and you measure 3mm that means the wall is bowing outwards 5- 3= 2mm and you can shave the extra 2mm off to return the wall to flat. 0mm . When you lay your new sheet it should be very close to flat.

Look at the diagram showing string lines and a pretend timber stud profile going from a radical +1 to -10mm fluctuations add packers and shave wall back to 0mm . This can be applied to your wall whether you remove your first sheet of dry wall or add another sheet of villaboard on top.

A straight edge is great for many things you can measure the gap under the edge to the timber for the shims (hard to do one person) but if you get a bow it causes you to take straight edge off your two top and bottom rails. You will know its a bow so I guess you can plane that a bit and try again.

Well if you wish strip that dry sheet out not to costly i hope for you.

I hear you as to all that timber behind the wall a night mare of ups and downs I am very sure your seeing. But the benifit is the more timber the more avaliable fixing point for packers.

Lets call your vertical wall 0mm from top to bottom. Shave the high spots to 0 mm pack the low spots outwards to match 0mm on every stud making sure noggings and extra wall timber are not protruding past 0mm.

Good luck with your options I so hope my info isnt to taxing to read and understand

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shower liner to go on bowed drywall

The fibreglasss/acrylic sheet comes as a moulded right angle. So yes it covers all sorts of blemishes but in this case, after discussion with plumber last night, the danger is that the liner _might_ pull away from the wall "sometime" in the future (more headaches). 5mm is bad, but not game ending.

However I hate doing a pisspoor job, and trouble shooting is why I put the two critical sheets in first...just in case.

I thought I'd checked it enough and had it nailed (or screwed and glued in this case). But apparently screwed up was all it was.

I had a builder's line in my puch, and you're right - I should of popped a screw in top and bottom plate and checked that it was flat. I tend not to use it as much as I should and relay on the level as "good enough" for most stuff. The thing I hate about the builders line is that whenever there is a bump or protrusion it puts all the other measurements out by that little bit. I've got a chalk pinger but that's not good over long distances and I have to have the right angle and isn't any good for concave stuff.

I'm thinking by using a wider bit of timber or my level, given my angle, I might not been able to see the 1-1.5mm gap. the light not getting through the gap due the thickness of the tool, giving a shadowed effect. A line would have showed the 5mm much clearer and is narrow.

At least the Straight Edge/screed I will spot inwards bows much more easily, since it will rock on the high points. I can also draw a pencil against it, which I can't do with a string line.

Thanks for taking time to draw out the picture it did help. My mind was set on using a full fillet packer, like would be used in fine furniture - which is why a steady 5mm to 0mm is a fiddle to get right. My table saw died on the last job (brushes?). But you're right, I can do it with shorter pieces (eg 300mm long) tailored to the specific fixing point, since the dry sheet goes over it, and the liner will spread the human load a bit so the edge of the dry sheet won't be at risk to impact loads (note in last job I tripped over water bottle and dented the joined piece I'd backbraced, so bit sus on poorly supported drywall now...)

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.

![20221202_211433[1].jpg 20221202_211433[1].jpg](https://www.workshop.bunnings.com.au/t5/image/serverpage/image-id/60593iE40B21356F894F87/image-size/large?v=v2&px=999)

![20221202_211203[1].jpg 20221202_211203[1].jpg](https://www.workshop.bunnings.com.au/t5/image/serverpage/image-id/60594i0CEF2FDC991DF4A9/image-size/large?v=v2&px=999)